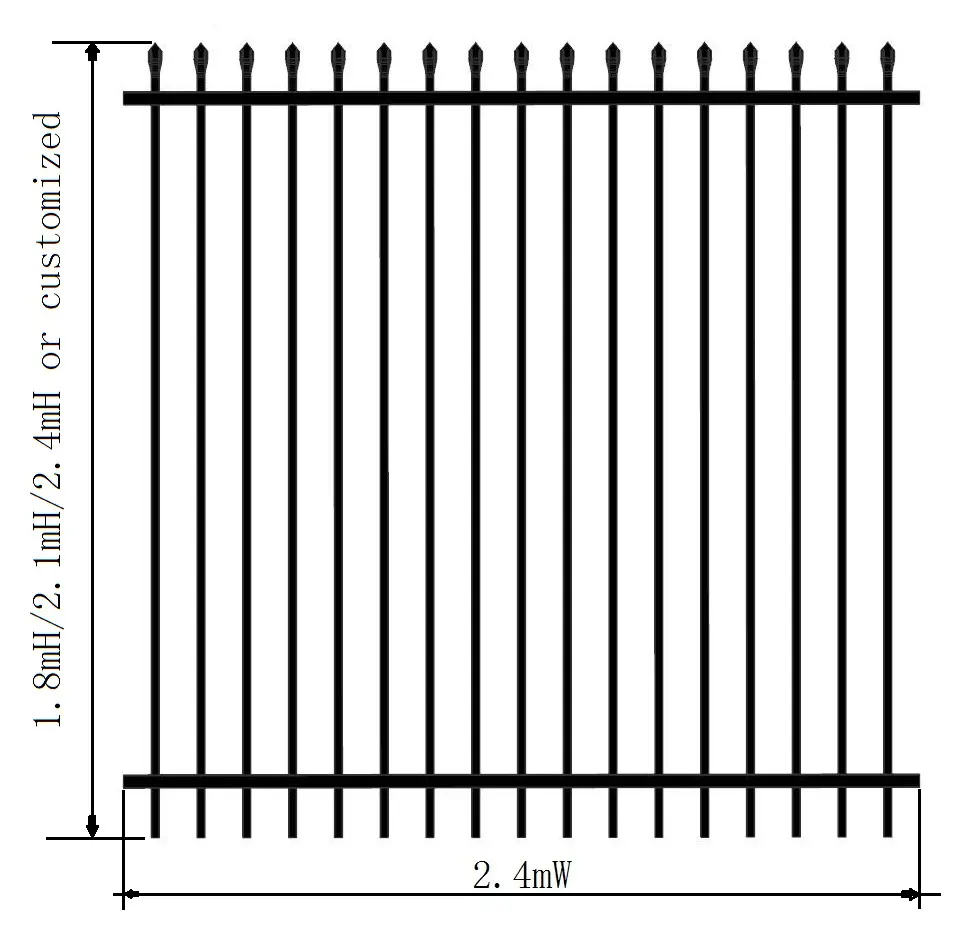

spear top aluminum fencing

- Fasteners standard: AS 1214 (304 stainless steel)

- Coating/performance standard: AS/NZS 3715

- Protective coating guidance: AS/NZS 2312.2

- Government security alignment: CPNI-aligned design ethos

- Panel material: 6063-T6 aluminum alloy

- Alternate strength note: 6063-T5 typical yield ≥160 MPa

- Steel equivalence: ≈275 MPa yield equivalent strength at ~65% less weight than mild steel

- Spear tops: 50 mm, marine-grade aluminum, anti-climb deterrent

- Welding: Robotic MIG, ISO 3834-2 certified

- Salt-spray resistance: 3,000 hours (coating system)

- Corrosion protection (3-stage): chromate conversion + epoxy primer + UV-stable polyester topcoat

- Total coating thickness: ≥80 μm

- Service life (typical): ≥25 years urban; ≥15 years coastal

- Installation efficiency: pre-assembled + CNC-punched holes; ~40% labor reduction

- Color options: Custom RAL / Colorbond® matches

- Description

BMP is a leading China-based manufacturer and supplier of spear top aluminum fencing for commercial, industrial, and residential sites. Our systems are designed to meet the rigorous demands of AS 4421:2019 Level 2 security environments while preserving clean, modern lines and long-term durability.

Why Our Fences Stand Out

-

Deterrence by design: Precision-formed 50 mm spear tops in marine-grade aluminum provide both a strong visual barrier and functional anti-climb protection.

-

Built for harsh sites: From government facilities seeking CPNI-aligned barriers to coastal properties facing salt spray, our finishes and fasteners are specified for high-corrosion environments.

-

Strength without weight: Panels use 6063-T6 aluminum and deliver structural equivalence to mild steel (≈275 MPa yield) at ~65% lower weight for easier handling and faster installs.

-

Three-stage corrosion protection:

-

Chromate conversion coating

-

Epoxy primer

-

UV-stable polyester powder topcoat

-

-

Weld integrity you can trust: ISO 3834-2 robotic MIG welding ensures joint consistency and panel stiffness. Assemblies are validated to 8 kN/m lateral loading per AS 1170.1.

Configurations & Bespoke Engineering

Standard panel heights range from 1800 mm to 2400 mm. Our engineering team can tailor:

-

Spear geometry and picket spacing for security or pool-safe requirements (including solutions aligned with AS 2156).

-

Post spacing and footing design for site wind loads.

-

Ground-penetrating systems for either concrete footings or driven posts.

Product Specifications spear top aluminum fencing

Spear Top Panel Options (Powder Coated Finish)

2400 H (mm) × 2400 W

| Horizontal Rail | Vertical Picket | Weight (kg) |

|---|---|---|

| 40×40×2.5 | 25×25×2.0 | 25.15 |

| 40×40×2.0 | 25×25×1.6 | 20.58 |

| 40×40×1.6 | 25×25×1.2 | 16.63 |

2100 H (mm) × 2400 W

| Horizontal Rail | Vertical Picket | Weight (kg) |

|---|---|---|

| 40×40×2.0 | 25×25×1.6 | 18.49 |

| 40×40×1.6 | 25×25×1.2 | 14.29 |

1800 H (mm) × 2400 W

| Horizontal Rail | Vertical Picket | Weight (kg) |

|---|---|---|

| 40×40×2.0 | 25×25×1.6 | 16.43 |

| 40×40×1.6 | 25×25×1.2 | 12.70 |

Materials: Panels constructed from 6063-T6 aluminum alloy.

Spear Tops: 50 mm, marine-grade aluminum.

Accessories — Fence Posts

| Post Size (mm) | Length (mm) | Weight (kg) |

|---|---|---|

| 65×65×3.0 | 3000 | 6.05 |

| 2700 | 5.44 | |

| 2400 | 4.84 | |

| 65×65×2.5 | 3000 | 5.08 |

| 2700 | 4.57 | |

| 2400 | 4.06 | |

| 65×65×2.0 | 3000 | 4.10 |

| 2700 | 3.69 | |

| 2400 | 3.28 |

Color Options

We powder coat in custom RAL or Colorbond®-matched colors. Provide your color number and we’ll produce samples for approval.

Performance Advantages spear top aluminum fencing

- High-strength aluminum: 6063 series alloy (typical ≥160 MPa yield in T5 and higher in T6), coating systems aligned with AS/NZS 3715 and tested to 3,000-hour salt spray—ideal for coastal sites.

- Stainless fasteners: AS 1214-certified 304 stainless hardware maintains connections under 8 kN/m horizontal loading (AS 1170.1).

- Robotic welded connections: ISO 3834-2 processes at critical joints deliver stiffness consistent with AS 4687 lateral load performance.

- Customizable geometry: Heights 600–3000 mm, picket spacing 50–200 mm, and any RAL/Colorbond® color to meet site security and aesthetics.

- Fast installation: Pre-assembled panels and CNC-punched connection points cut on-site labor by ~40%; compatible with AS 3600 concrete footings or driven posts.

- Factory-direct value: Typical 15–20% cost advantage versus local distributors.

- Extended service life: 25+ years in urban settings and 15+ years in coastal zones (finishing practice aligned with AS/NZS 2312.2).

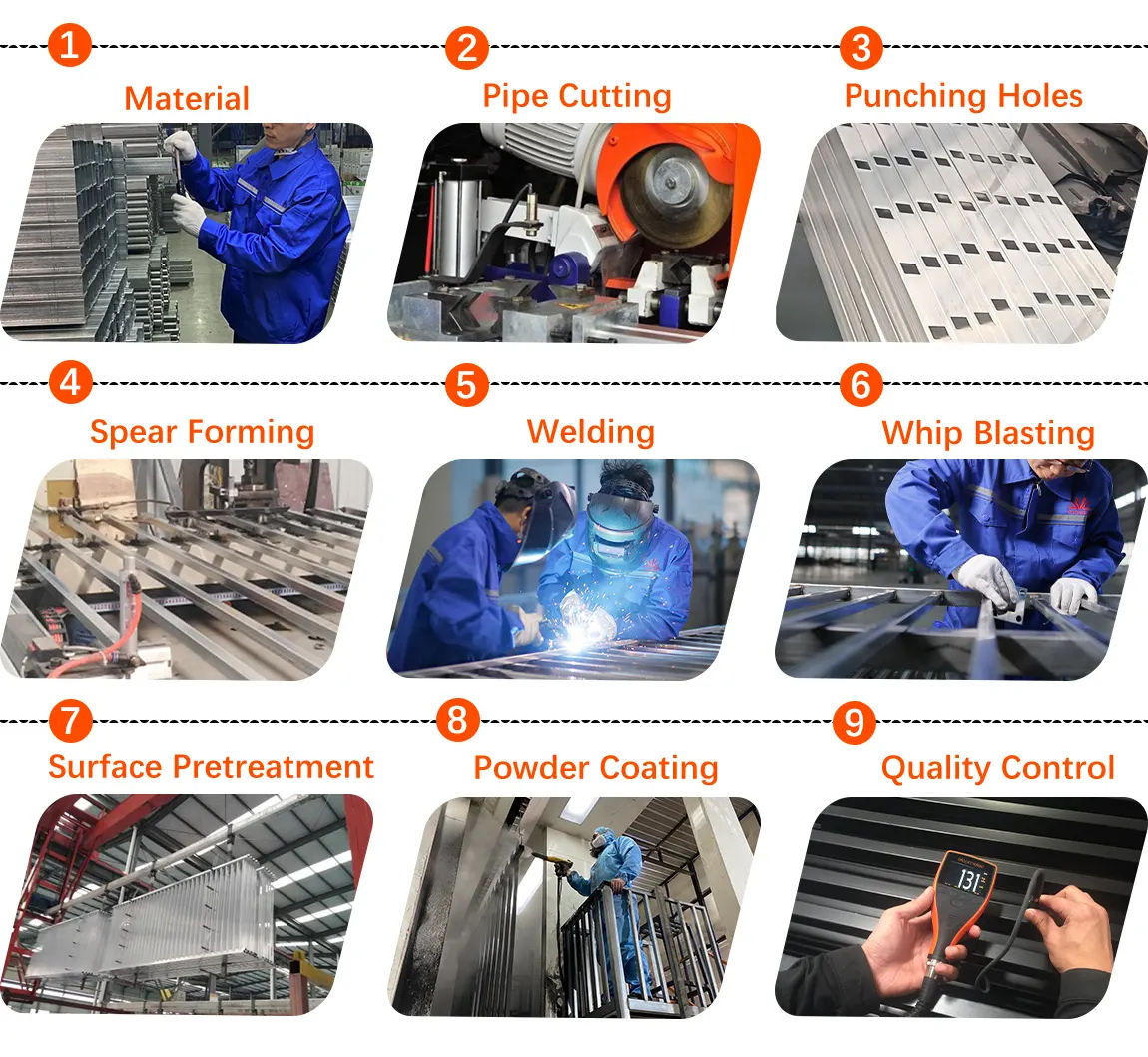

Manufacturing Process

- Material inspection – Verify OD, wall thickness, and cut lengths; reject any surface-defective stock.

- Precision cutting – Calibrated saws deliver clean, accurate lengths for rails, pickets, and posts.

- CNC punching – Consistent, jig-controlled hole patterns for fasteners and brackets.

- Spear forming – Automated shaping ensures uniform 50 mm spear profiles.

- Robotic MIG welding – ISO 3834-2 certified processes for repeatable, high-strength joints.

- Surface cleaning – Post-weld blasting removes residues and prepares surfaces.

- Pretreatment – Chromate conversion plus pure-water rinses enhance corrosion resistance and coating adhesion.

- Powder coating – Epoxy primer + polyester topcoat electrostatically applied and oven-cured.

- Quality control – Cross-cut adhesion checks and micrometer verification of ≥80 μm total coating thickness.

Typical Applications spear top aluminum fencing

- Residential: Yards, gardens, and pools—security with curb appeal.

- Decorative: Elegant boundary definition for frontages and patios.

- Commercial: Professional perimeter security that remains welcoming.

- Parking areas: Clear demarcation and access control.

- Parks & recreation: Playgrounds, sports fields, walkways—safety with visibility.

- Industrial: Warehouses and factories—non-rusting, low-maintenance security.

|

|

|

|

Frequently Asked Questions spear top aluminum fencing

Is the fence customizable?

Yes. BMP tailors sizes, picket spacing, and finishes to your project. Our engineers can assist with site-specific design and documentation.

How easy is installation?

Panels arrive pre-assembled with CNC-punched holes. Aluminum’s low weight simplifies handling and speeds installation, reducing labor time.

Which properties is it suited for?

Homes, schools, businesses, and industrial facilities—anywhere that requires credible security without sacrificing appearance.

How does the spear top enhance security?

The 50 mm spear profile acts as a visual deterrent and anti-climb feature, helping prevent unauthorized access.

What maintenance is required?

Aluminum won’t warp, rot, or rust. Rinse periodically with mild soap and water to keep the finish looking new.

How do I request a quote?

Share your drawings or basic dimensions, target height, color, and any standard requirements. BMP will provide a tailored quotation promptly.

Aluminum fence