Rubbish Bin Cage – Durable and Portable Waste Solutions by BMP

- Price: $48.33 - $111.22

- MOQ (Minimum Order Quantity): 100 kits

- HS Code: 73809000

- Production Time: 7-14 days

- Customized: Available

- Size: 1.5m x 1.8m x 1.8m or customized

- Finish: Hot-dipped galvanized

- Description

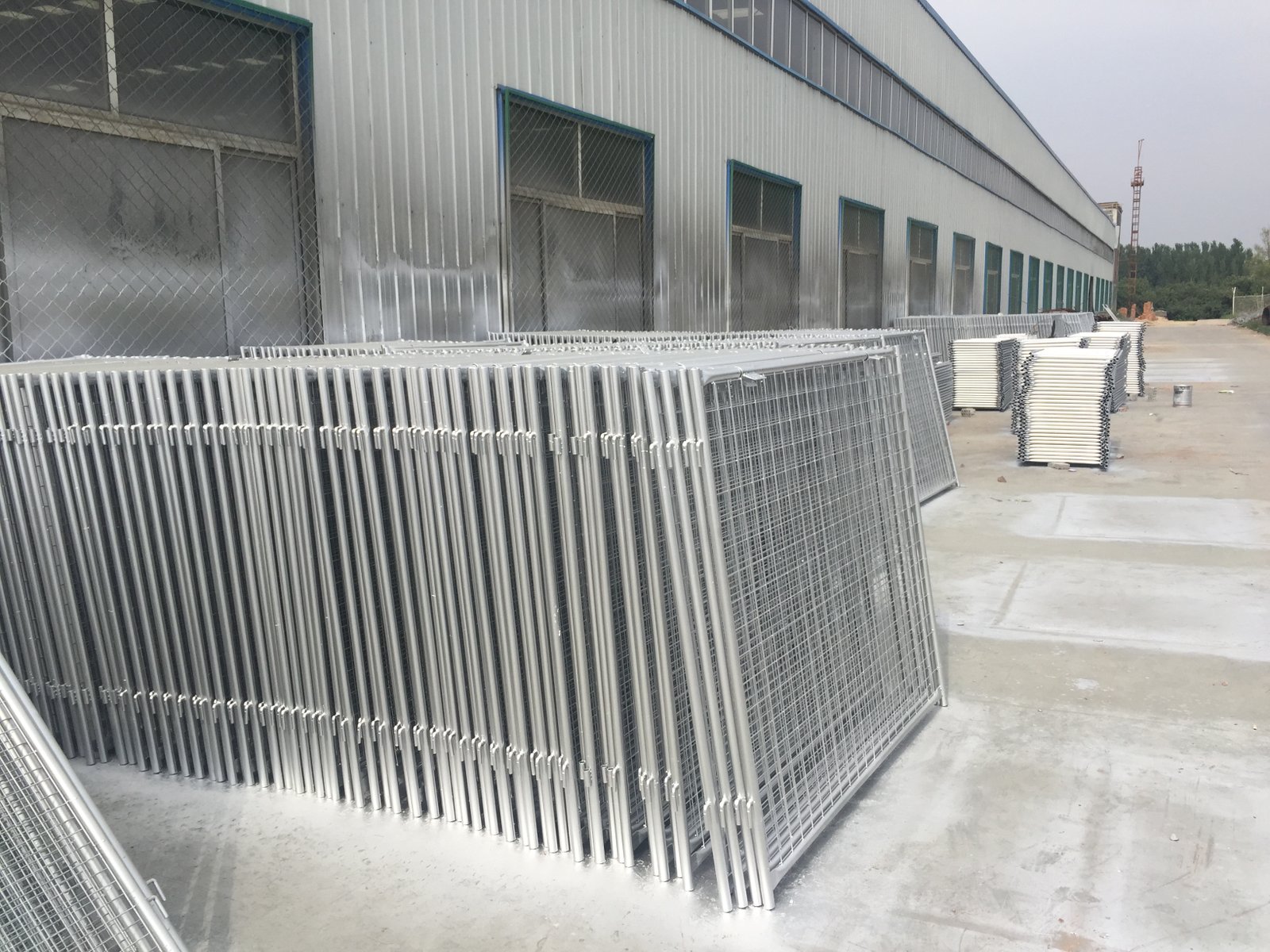

Maintaining a clean and organized construction site is essential for smooth operations and compliance with environmental standards. BMP’s rubbish bin cage offers a practical and durable solution for waste containment across construction and industrial sites. With their robust, portable design, these cages are easy to assemble, providing long-lasting performance and effective waste management.

What is a Rubbish Bin Cage?

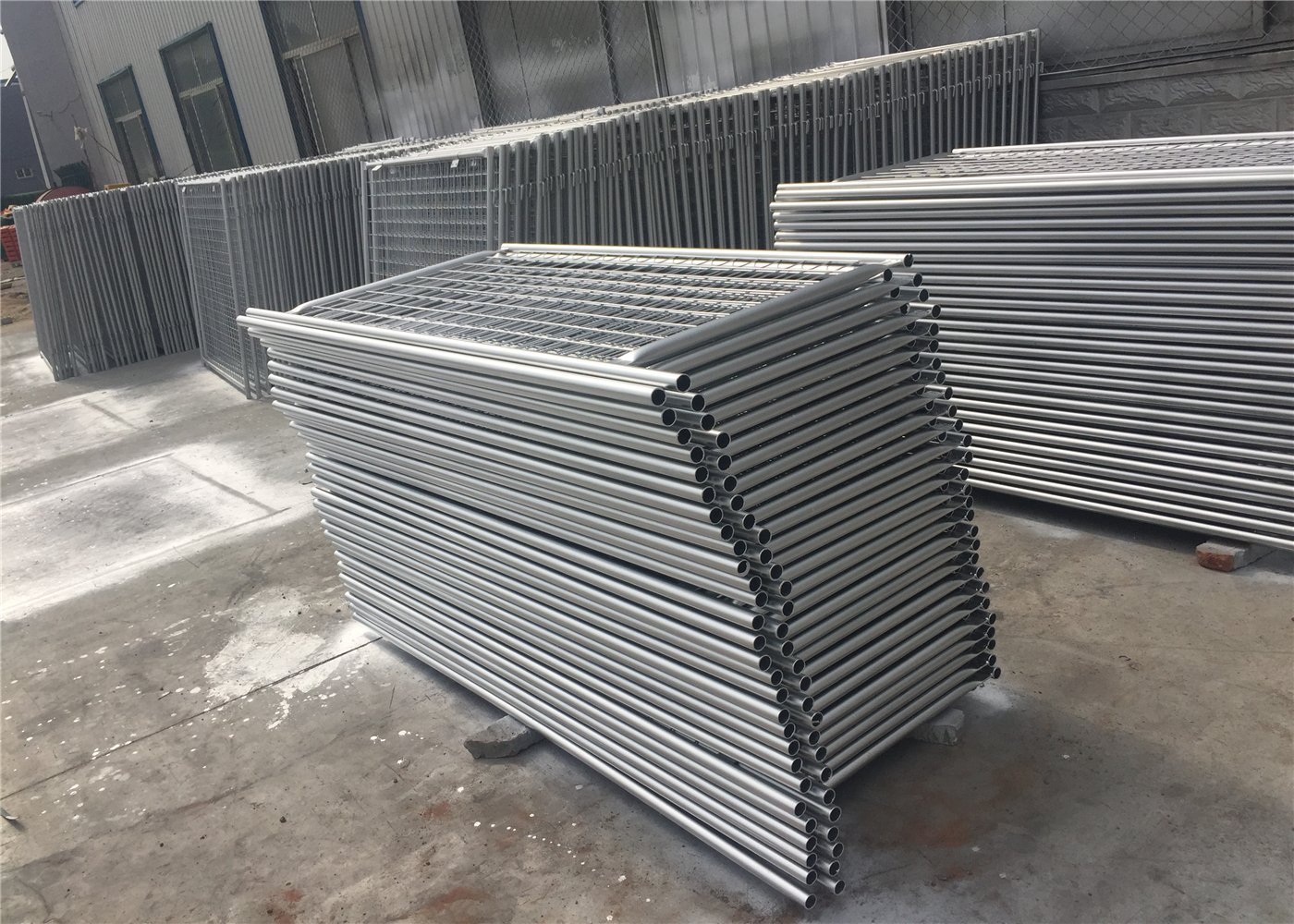

A rubbish bin cage is a heavy-duty, welded wire structure used to securely hold and contain waste materials on construction and demolition sites.BMP manufactures its rubbish bin cages using hot-dipped galvanized steel for rust resistance, ensuring they withstand harsh site conditions. These portable cages feature panels, gates, and clamps that assemble quickly to create a reliable waste containment system.

Key Features

- Durable Construction: Made with hot-dipped galvanized steel for rust resistance and long-term strength.

- Portable and Lightweight: Designed for easy assembly, disassembly, and transportation between job sites.

- Strong Framework: The welded mesh panels supported by steel pipes create a sturdy structure that withstands heavy loads.

- Customizable Options: Choose from various sizes, pipe diameters, and configurations to meet specific project requirements.

- UV Protection: The base is made from UV-resistant polypropylene to protect against sun damage.

- Cost-Effective: The reusable design reduces waste management costs over multiple projects.

Specifications

| Component | Specifications |

|---|---|

| Height | 1500mm |

| Length | 1800mm |

| Frame Pipe Options | 32mm (Standard), 42mm, 48mm OD (Optional for stronger frames) |

| Frame Pipe Thickness | 2mm |

| Mesh Aperture | 50mm x 50mm, 60mm x 150mm |

| Wire Diameter | 4mm |

| Finish | Hot-dipped galvanized |

| Clamps | 12 clamps included for assembly |

| Base Dimensions | 600mm x 220mm x 150mm (L x W x H) |

| Base Material | UV-resistant polypropylene, designed to be filled with concrete |

| Panel Components | 4 panels, 2 gates/lids |

Why Choose BMP’s Rubbish Bin Cage?

- Durability and Strength

The hot-dipped galvanized finish ensures resistance to corrosion and rust, making these cages ideal for long-term use in demanding environments. The 4mm wire mesh and welded construction provide robust strength to handle heavy loads. - Easy Assembly and Portability

BMP’s rubbish bin cages feature a flat-pack design, allowing for easy transport and quick assembly at the job site. Clamps and welded hooks ensure secure connections between panels, gates, and lids. - Cost-Effective Solution

Unlike disposable waste solutions like skip bins, BMP’s cages are reusable and require minimal maintenance, offering significant cost savings over time. - Enhanced Safety and Environmental Responsibility

BMP’s cages help prevent waste from blowing away in windy conditions or during transportation, promoting safety on site. They also ensure compliance with Australian waste management regulations, reducing environmental impact.

Applications of BMP’s Rubbish Bin Cage

BMP’s rubbish bin cages are versatile and well-suited for various waste management tasks:

- Construction Sites: Securely contain building and demolition waste.

- Industrial Projects: Manage industrial debris and scrap materials effectively.

- Public Events: Efficient waste collection for festivals, concerts, and sporting events.

- Residential Projects: Keep waste organized during home renovations or landscaping projects.

FAQ – Rubbish Bin Cages

1. What is a rubbish bin cage?

A rubbish bin cage is a durable, welded wire structure designed to contain waste securely at construction or industrial sites. BMP’s cages are portable, long-lasting, and easy to assemble for efficient waste management.

2. What materials are used in BMP’s rubbish bin cages?

BMP’s cages are made with hot-dipped galvanized steel for corrosion resistance, and the base is constructed from UV-protected polypropylene.

3. What sizes are available for BMP’s rubbish bin cages?

BMP offers standard dimensions of 1500mm in height and 1800mm in length. Custom sizes are available based on project requirements.

4. Can I use a rubbish bin cage for multiple projects?

Yes, BMP’s cages are reusable and built to last, making them ideal for use across multiple sites.

5. How do I assemble a BMP rubbish bin cage?

Assembly is simple: connect the panels, gates, and lids using the included clamps. For added stability, you can fill the base with concrete.

6. Are rubbish bin cages cost-effective compared to skip bins?

Yes, rubbish bin cages are a more affordable, long-term solution. Their reusable design reduces costs over multiple projects, while requiring minimal maintenance.

7. Can BMP customize rubbish bin cages?

Yes, BMP offers customizable options for dimensions, pipe sizes, and other features to meet specific needs.

Conclusion: Rubbish Bin Cages – The Ideal Waste Management Solution

BMP’s rubbish bin cages provide a durable, portable, and cost-effective alternative to traditional waste management methods like skip bins. With their hot-dipped galvanized finish, UV-resistant base, and easy-to-assemble design, these cages ensure secure and efficient waste containment on construction and industrial sites. By reusing them across multiple projects, you’ll save money while maintaining environmental responsibility and compliance.

Contact BMP today to learn more about our rubbish bin cages or request a customized solution tailored to your next project!

Rubbish Cages