Powder coating is a modern, environmentally friendly finishing technique used extensively to protect and beautify metals and other surfaces. Unlike conventional liquid paints, powder coatings use dry, powdered formulations composed primarily of polymer resins, pigments, curatives, and additives. These powders are electrostatically charged and applied to the surface of the material, creating a uniform, attractive, and durable protective layer after curing. Due to its exceptional chemical stability, physical strength, and superior UV resistance, powder coating has become the preferred choice in industries ranging from construction and architecture—particularly for outdoor applications like temporary fencing, crowd control barriers, garrison fencing, and gates,clearvu fence—to consumer goods and industrial equipment.

What is Powder Coating?

Powder coating is a dry finishing method commonly used to apply protective and decorative coatings onto metals and various other materials. Unlike traditional liquid paints, powder coatings do not require solvents. Instead, they involve electrostatically spraying a finely ground powder, typically composed of polymer resins, pigments, curatives, and specialized additives onto the surface of an object. Once coated, the item is cured in an oven, resulting in a durable, uniform, and high-quality finish.

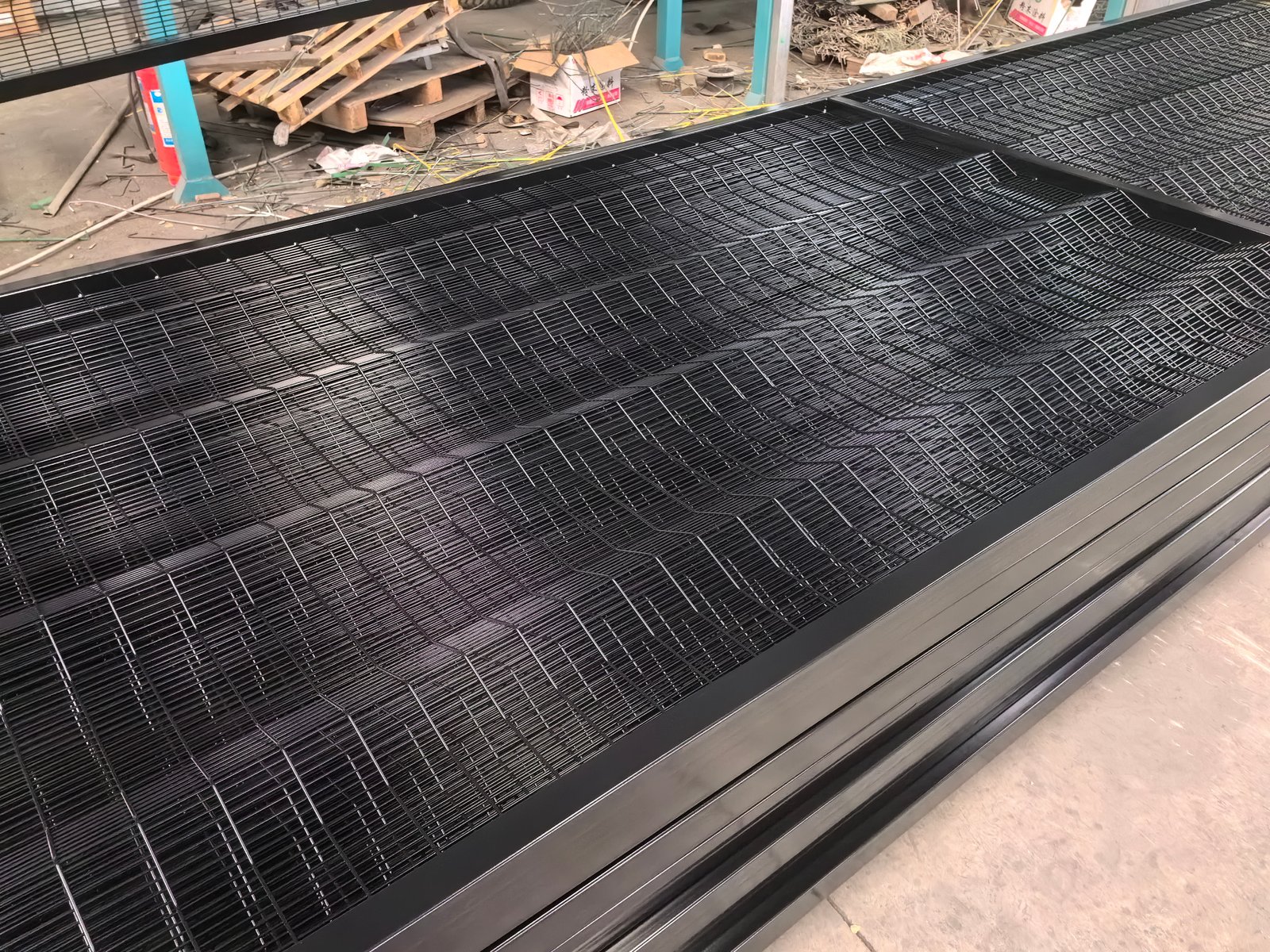

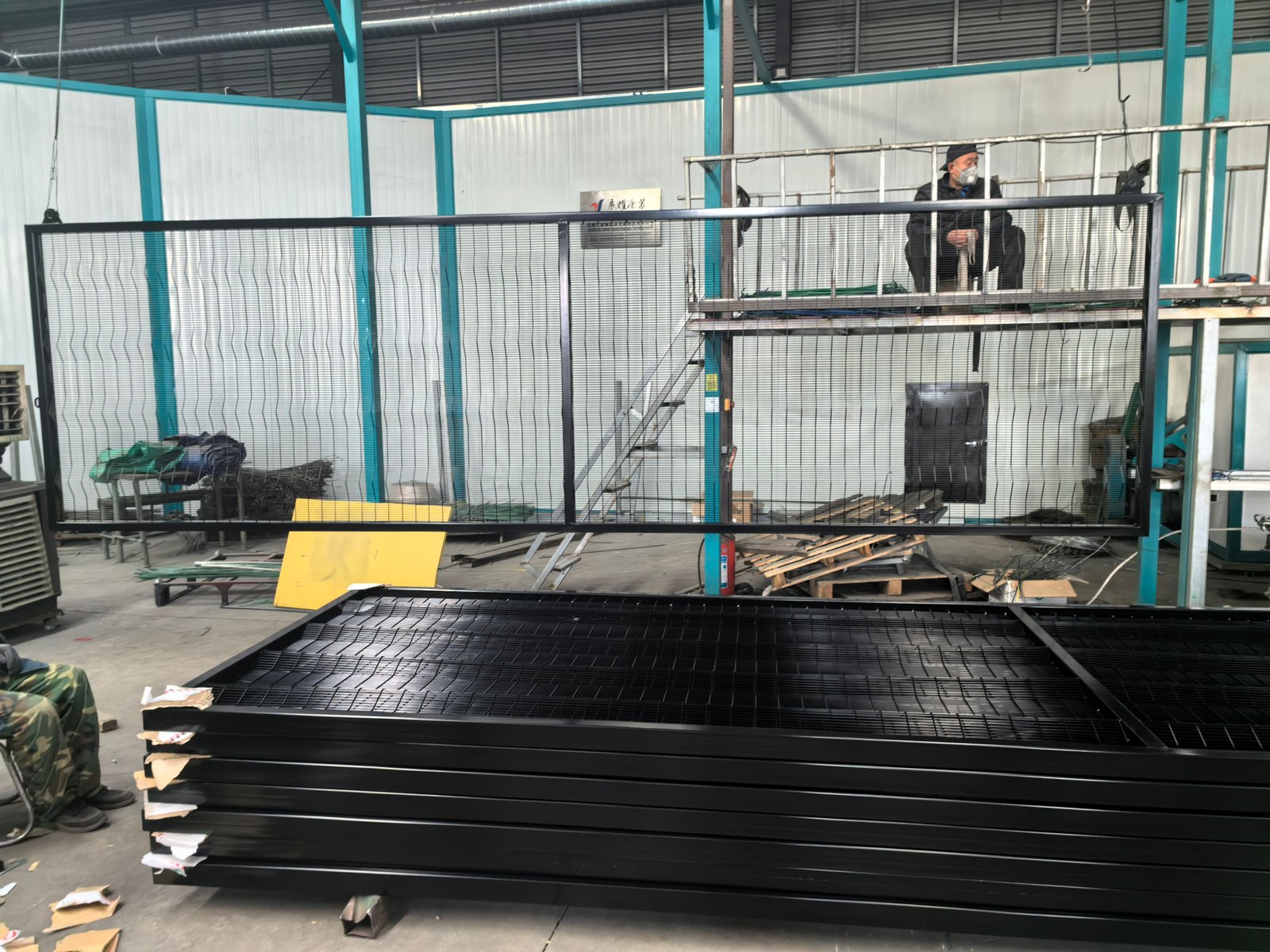

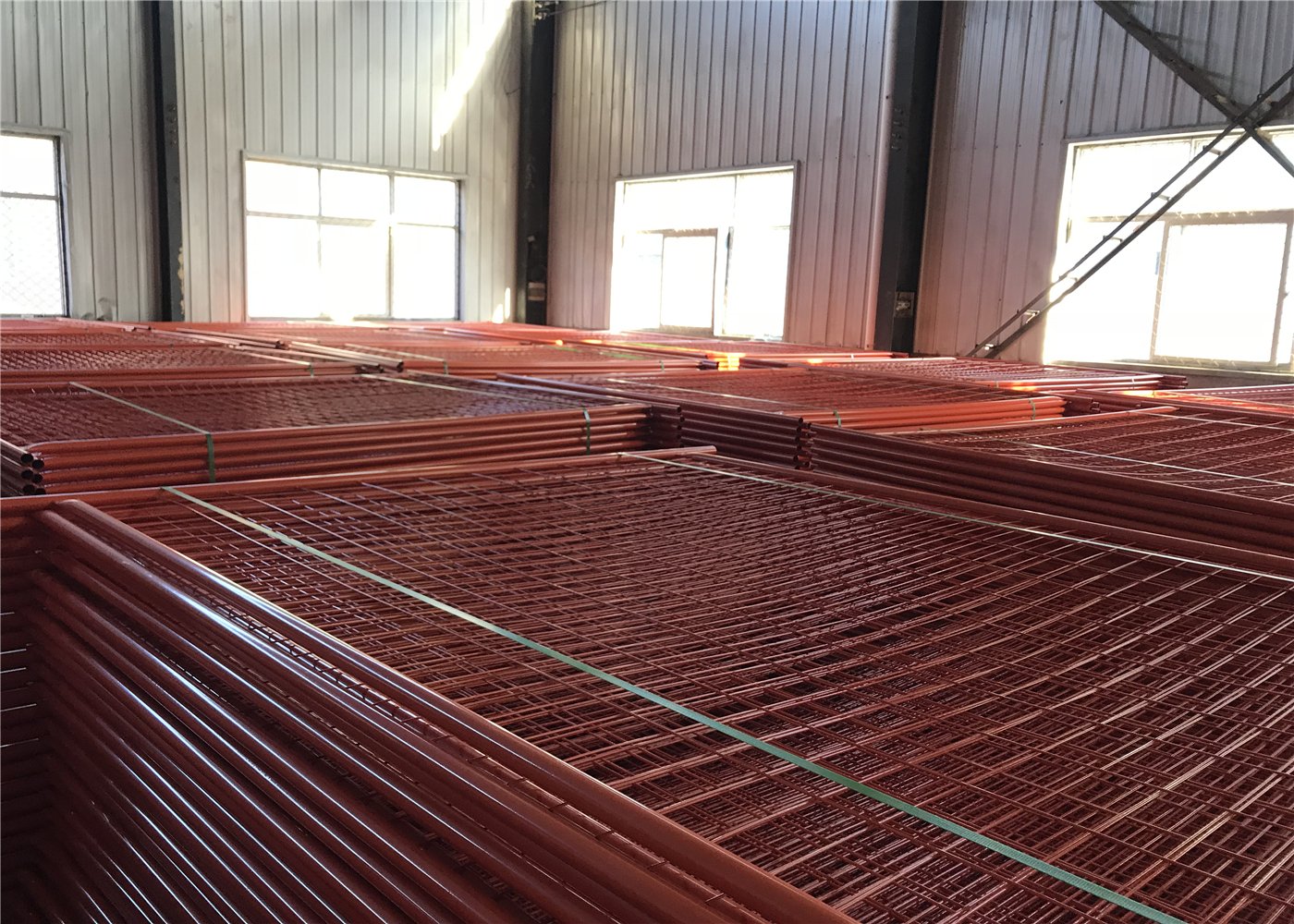

Powder coatec clearvu fence

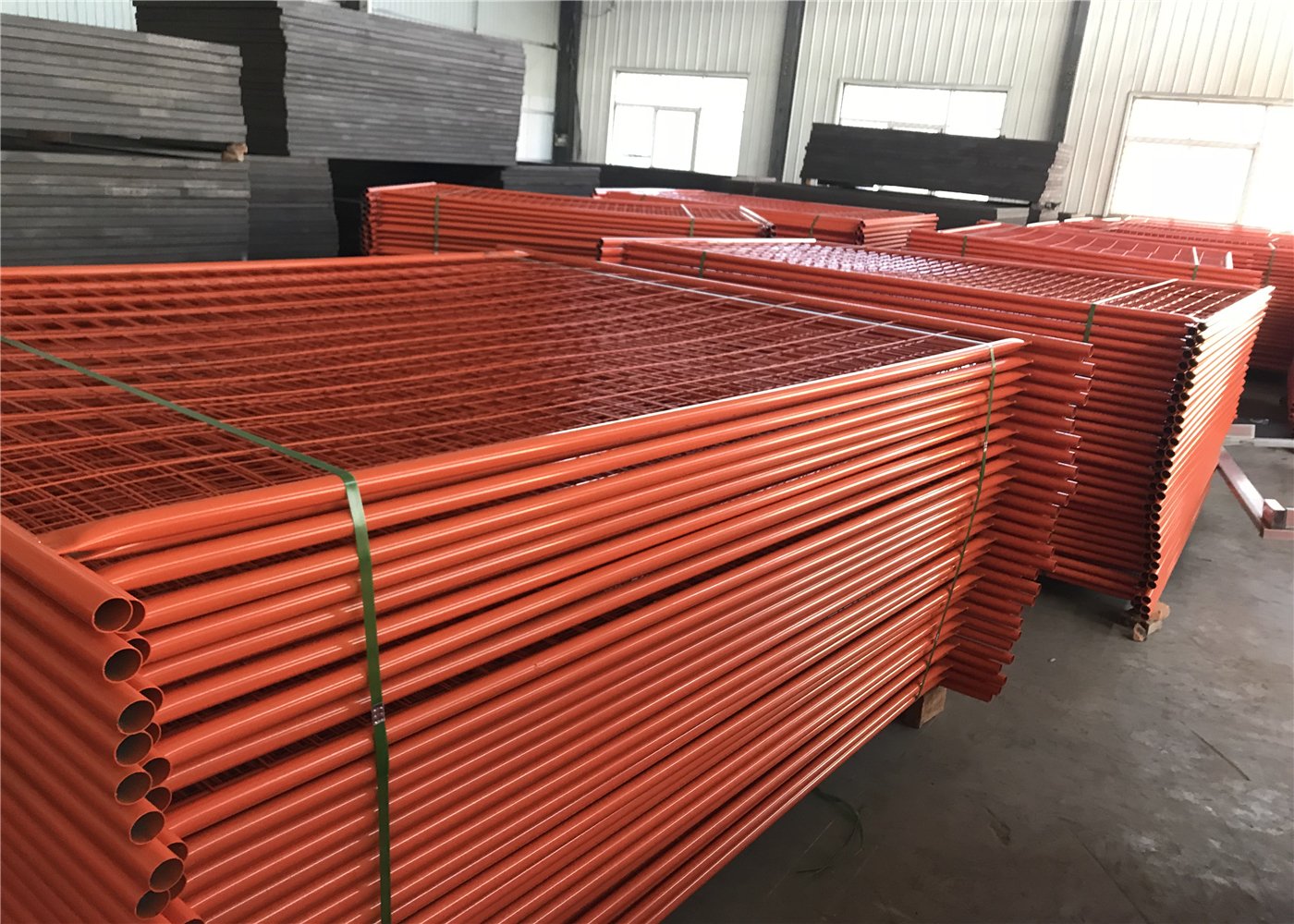

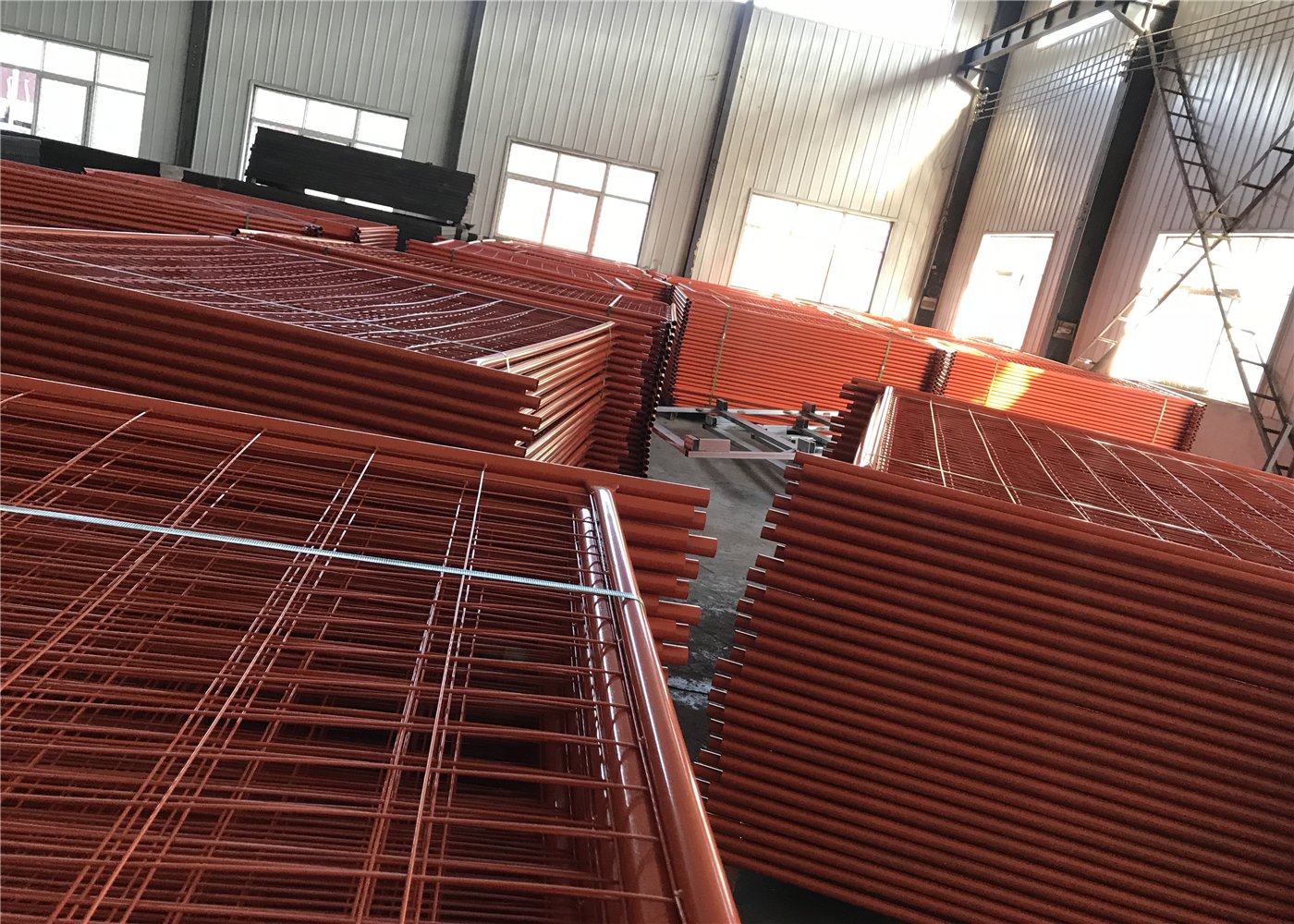

Temporary Fencing Surface Treatment Powder RAL 2009 Coated

Crowd Control Barriers -Powder coated

Chemical Composition of Powder Coatings

Powder coatings typically consist of four primary components:

1. Resins (Polymers)

Resins define the fundamental characteristics and performance of the coating. Common resins include:

- Polyester Resins: Offer excellent UV and weather resistance, ideal for outdoor applications like fencing, gates, and architectural elements.

- Epoxy Resins: Provide superior chemical and corrosion resistance but are susceptible to UV degradation, making them ideal for indoor applications or primers.

- Hybrid (Epoxy-Polyester) Resins: Balance chemical resistance and appearance quality, suitable for indoor applications such as household appliances.

- Acrylic Resins: Excellent color retention, gloss stability, and UV resistance, suitable for premium outdoor uses.

2.Powder Coatings Pigments

Pigments provide color and opacity, enhancing visual appeal and protective qualities. Typical pigments include:

- Inorganic Pigments: Titanium dioxide (white), iron oxides, carbon black—known for stability and UV resistance.

- Organic Pigments: Offer vivid colors but may have lower UV resistance.

3. Curatives (Cross-Linkers)

Curatives chemically react with resins during curing, creating a tough, stable coating. Common curatives include triglycidyl isocyanurate (TGIC), glycidyl esters, and dicyandiamide.

3. Flow Modifiers

Flow modifiers, such as acrylic copolymers, improve surface smoothness, minimize imperfections, and enhance aesthetic quality.

4. Other Additives

Various additives enhance additional characteristics, including:

- Degassing agents (e.g., benzoin) to prevent surface defects caused by gas formation.

- UV Stabilizers: Including Hindered Amine Light Stabilizers (HALS) and UV absorbers, protecting coatings from UV degradation.

Chemical and Physical Properties of Powder Coatings

Chemical Properties

- Corrosion Resistance: Excellent protection against oxidation and corrosive environments.

- Chemical Stability: Resistance to solvents, acids, and alkaline substances.

- Eco-friendly: Virtually no VOC emissions, making it environmentally safer compared to traditional liquid paints.

Physical Properties

- High Adhesion: Strong bond to substrates ensures longevity and reduces peeling.

- Durability and Abrasion Resistance: Withstands scratches, impacts, and abrasion.

- Flexibility: Maintains integrity under stress, preventing cracking and peeling.

- Thermal Stability: Typically stable at temperatures up to around 200°C (392°F).

- Uniform Coating Thickness: Achieves consistent film thickness, generally ranging from 50 to 150 microns.

Achieving UV Resistance in Powder Coatings

UV resistance is critical, especially for outdoor applications such as temporary fencing, crowd control barriers, garrison fencing, gates, and outdoor architectural components. UV resistance is achieved by incorporating:

1. UV-Stable Resins

Selecting UV-resistant resins such as polyester or acrylic ensures prolonged outdoor performance and minimizes degradation caused by sunlight.

2. UV Absorbers

Chemical compounds (e.g., benzotriazoles, benzophenones) that absorb and dissipate UV radiation, thus protecting pigments and resins from breakdown.

3. Hindered Amine Light Stabilizers (HALS)

HALS additives neutralize free radicals formed during UV exposure, significantly extending coating durability by preventing degradation and maintaining the coating’s appearance and integrity.

4. Pigment Selection

Choosing inorganic pigments (e.g., titanium dioxide) enhances UV stability and prevents color fading, preserving aesthetic quality over extended exposure.

Applications of Powder Coating

Powder coating is widely utilized due to its robustness, versatility, and superior finish. Key applications include:

- Architectural Elements: Temporary fencing, crowd control barriers, garrison fencing, gates, railings, window frames, and outdoor structures.

- Industrial Equipment: Machinery parts, tools, electrical enclosures, and structural components.

- Furniture and Fixtures: Outdoor furniture, metal shelving, racks, tables, and decorative items.

- Electronics & Consumer Goods: Appliances, bicycles, fitness equipment, electronics casings.

- Automotive Industry: Automotive trims, wheels, engine components, and exhaust systems.

Conclusion

Powder coating stands out as an advanced and efficient coating technique, offering exceptional durability, aesthetic versatility, environmental benefits, and cost-effectiveness. By carefully selecting chemical components, especially UV stabilizers and resins, powder coatings achieve outstanding performance in both indoor and outdoor applications, becoming an essential solution across various industries.