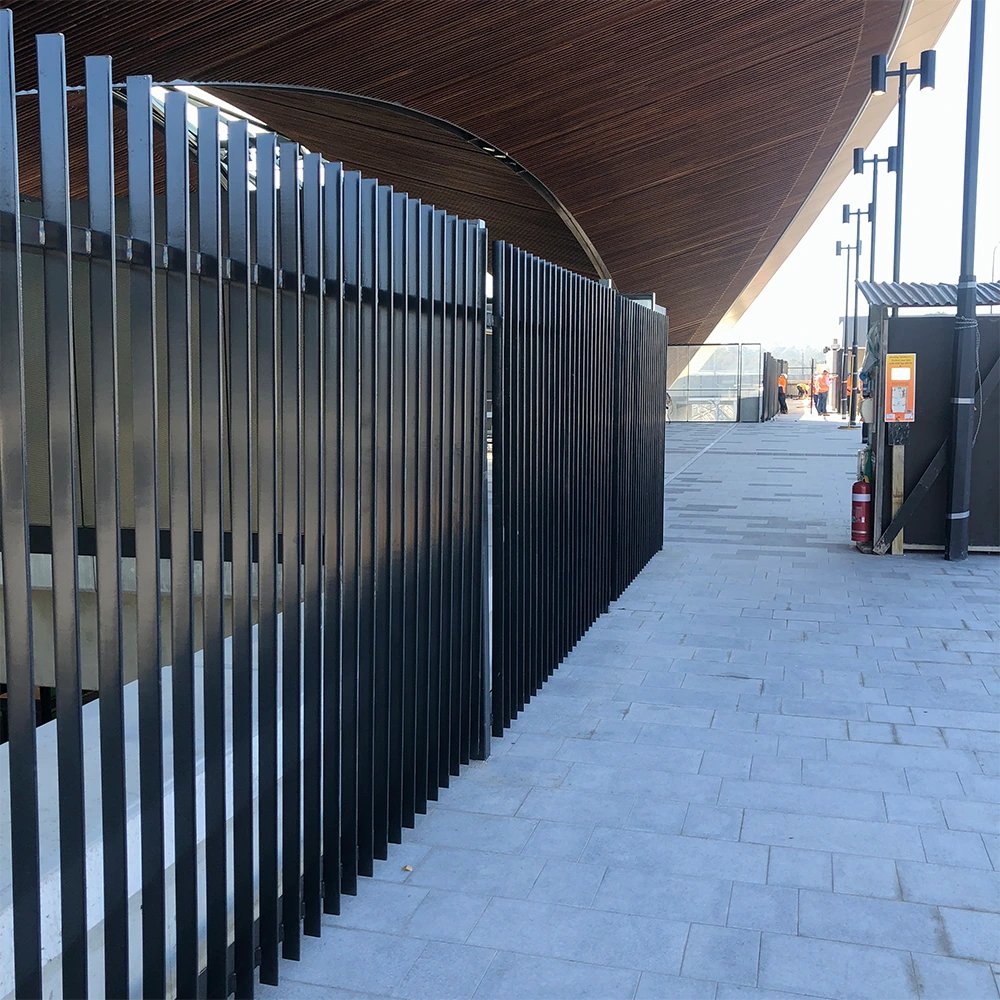

The BMP Metal Vertical Slat Fence is a purpose-built security system for commercial and industrial sites. Its clean, vertical-slat profile delivers a contemporary look while the welded construction provides real protection for assets and people.

Why Choose BMP Slat Fencing

-

Modern, distinctive look: Vertical slats create a unique architectural profile.

-

Security you can trust: Slat pickets are direct-welded to the rails for rigidity and durability.

-

Built for harsh environments: Hot-dip galvanizing and/or powder coating for corrosion resistance.

-

Material options: Standard galvanized steel; aluminum and stainless steel available on request.

-

Fast, clean installs: Compatible posts, brackets, and caps; modular system.

-

Customizable: Sizes, materials, colors, gaps, and workmanship to suit your project.

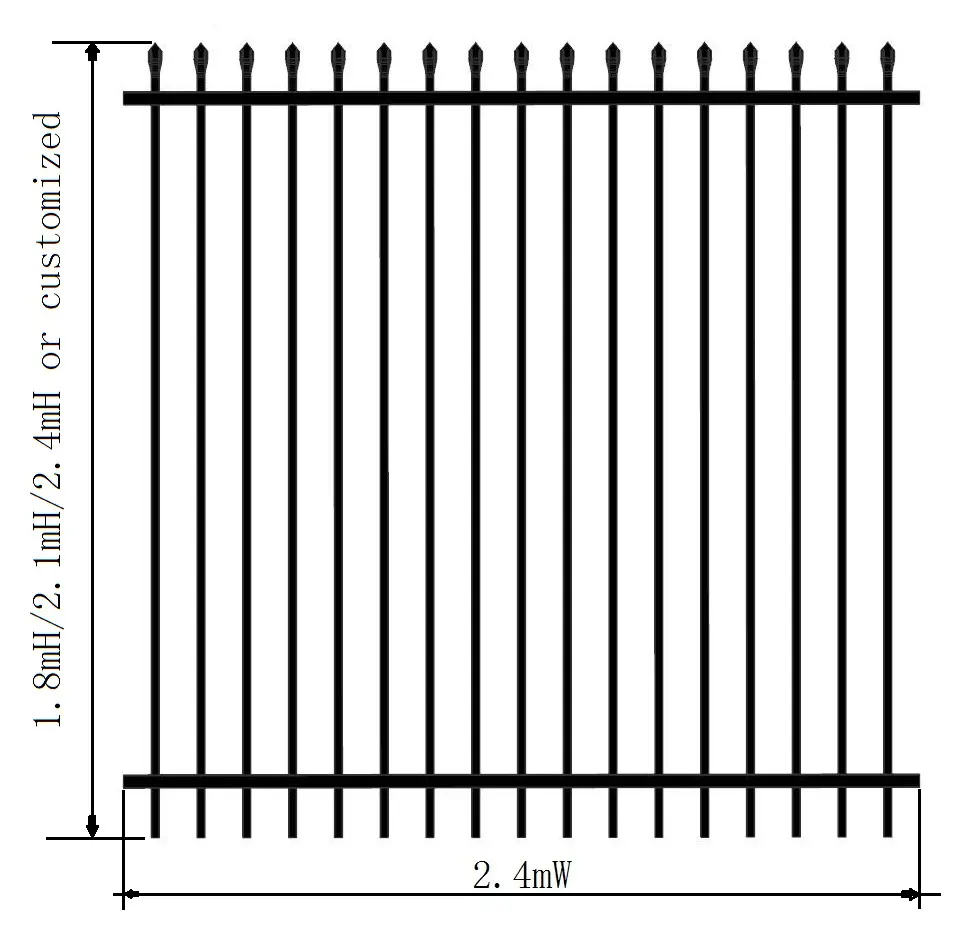

Metal Vertical Slat Fence Specifications

Model No.: FDCI113001

Standard panel sizes (mm): 2400×900 / 2400×1200 / 2400×1500 / 2400×1800 (custom sizes available)

Top & bottom rail: 40×40×1.6 mm

Slat picket: 65×16×1.2 mm

Slat pitch: Centre 46 mm, Gap 40 mm

Material: Galvanized steel (Aluminum / Stainless optional)

Finish: Hot-dip galvanized (HDG) and/or powder-coated (epoxy-polyester)

Colour: Black standard; custom colours available

Install note: Allow 10–14 mm total bracket gap so a 2400 mm panel fits a daylight opening of 2410–2414 mm.

|

|

Product Details

-

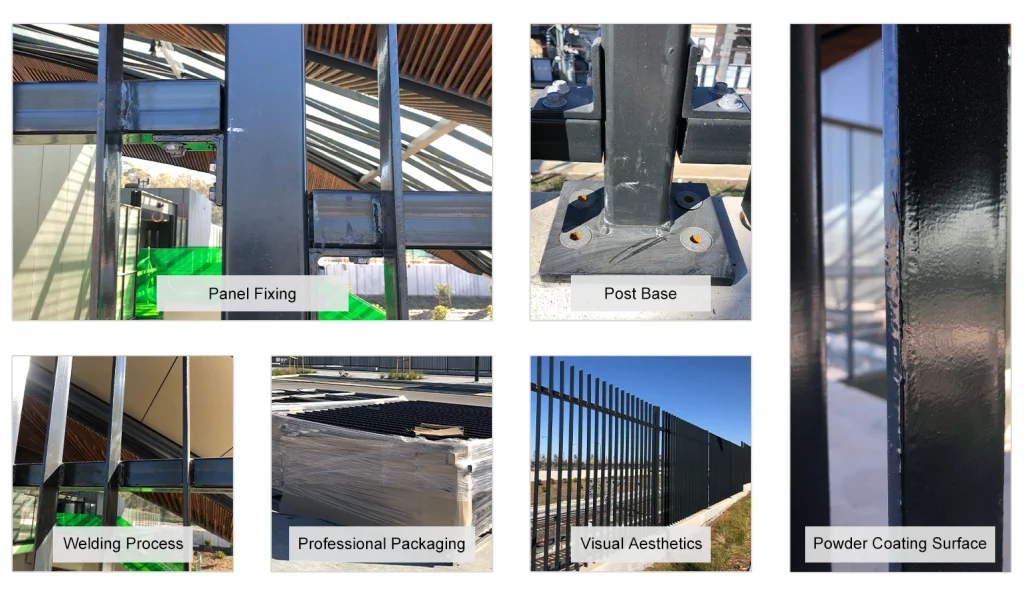

Installs with BMP posts, rail brackets, and fasteners—quick and convenient.

-

Optional post bases for slab mounting; stable and secure.

-

High-quality powder coat: anti-rust, anti-peel, and corrosion-resistant surface.

-

Precision welding for strong, durable panels with an even visual rhythm.

-

Protective packaging: wrapping film + cardboard + steel frame for safe transport.

Related Accessories Metal Vertical Slat Fence

-

Black metal flanged posts

-

Fence brackets / post brackets

-

Plastic square caps (polypropylene)

-

Screws and fixing hardware

Advantages

-

Signature vertical-slat aesthetic with strong security presence.

-

Accessory-driven install reduces labour and speeds deployment.

-

Multiple metals & finishes for the right strength-to-weight and environment.

-

HDG / powder coat delivers long-term anti-corrosion performance.

-

Broad use cases: commercial, industrial, craft/retail, and more.

-

High-standard manufacturing for consistent quality.

BMP Production Process

-

Material inspection: Verify tube dimensions and wall thickness per drawings.

-

Cutting: Precision cut to length.

-

Slat forming: Flatten/straighten tubing into slat profile.

-

Welding: Assemble and weld pre-galvanized steel into rigid frames.

-

Grinding & polishing: Remove slag/impurities; prep surface.

-

Galvanizing (HDG): Enhance corrosion protection and powder adhesion profile.

-

Powder coating: Epoxy-polyester, high-temp cure; min. film ≥80 μm.

-

Quality control: Check strength, wall thickness, and coating thickness on each panel.

-

Packaging: Professional crating for safe transport.

Applications Metal Vertical Slat Fence

-

Critical infrastructure: Data centres, electrical substations

-

Logistics: Warehouses, distribution hubs

-

Government & corrections: Secure perimeters and controlled areas

-

Retail & parking: Complexes, car parks, access control

FAQs Metal Vertical Slat Fence

-

Design support? Yes—send requirements (sketch/text); BMP engineering will design to spec.

-

Need it fast? We plan production to your quantities and types—contact us early.

-

Samples? Custom without tooling typically 7–10 days; sample free, freight collect.

-

Lead time? Depends on order volume; large-scale capacity for quick turnaround.

-

Customization? Yes—size, material, colour, workmanship, and accessories to suit your site.