Categories

- Recent Updates

Hot Dip Galvanized Crowd control barriers look similar in photos, but their real service life is decided by one thing: how well the steel is protected at the exact points that get scratched, stacked, dragged, and welded. Hot-dip galvanizing is one of the most effective corrosion systems for barrier fleets because it protects steel even after handling damage—if you choose the right production route.

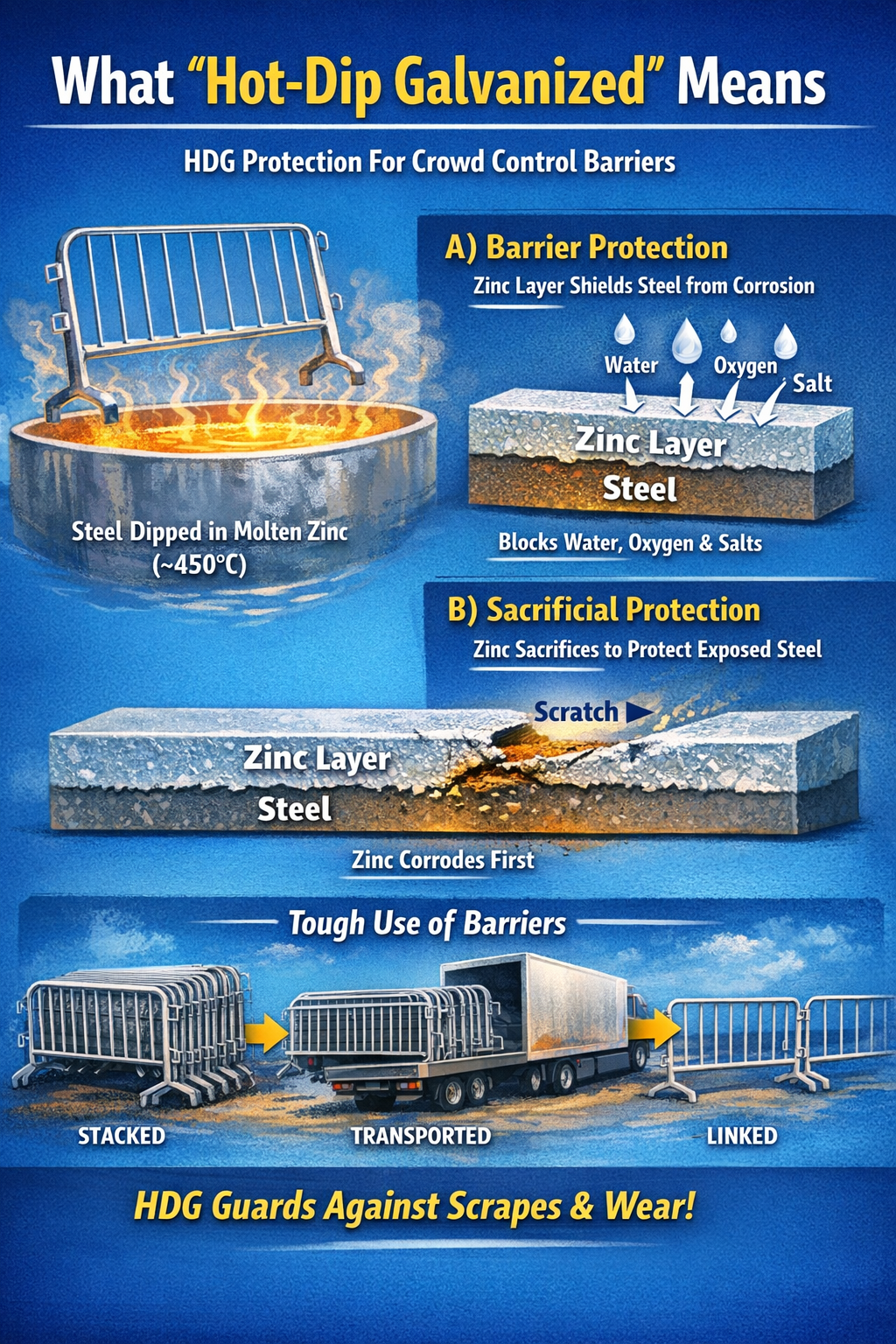

Hot-dip galvanizing (HDG) is a process where steel is cleaned and then dipped into molten zinc (around 450°C). The zinc doesn’t simply “coat” the steel like paint. It forms a metallurgically bonded zinc/iron layer system that is strongly attached to the steel surface.

HDG protects steel using two linked principles:

A) Barrier protection (physical shielding)

The zinc layer acts as a barrier between the steel and oxygen/water/salts, slowing corrosion reactions.

B) Sacrificial (cathodic) protection

Zinc is more reactive than steel. If the coating is scratched and steel is exposed, zinc will corrode first and help protect nearby steel—this is why small scratches don’t immediately become red rust.

Why this matters for crowd control barriers:

Barriers are constantly handled (stacked, transported, linked/unlinked), so scratches are normal. HDG’s sacrificial protection is the key advantage over coatings that only work when perfect.

“Service life” in barrier terms means: how long the barrier stays structurally reliable and visually acceptable without frequent rust repairs.

Early rust typically starts at:

The right Hot Dip Galvanized route is the one that protects these points and stays intact under abrasion.

Process: fully weld and assemble the barrier → then hot-dip galvanize the finished product.

Principle (why it usually delivers the longest outdoor service life):

Real barrier outcome:

Best choice for rental fleets, outdoor storage, coastal environments, and high-handling operations.

Key technical requirement:

Hollow sections need correct vent/drain design to avoid trapped chemicals/moisture inside tubes.

Hot dipped galvanized crowd control barriers

Process: Hot Dip Galvanized tubes/parts first → weld into a finished barrier later.

Principle (why weld areas rust early if not repaired):

How protection is restored (principle of repair):

Real barrier outcome:

If repairs are weak or inconsistent, you typically see rust rings at welds while the rest still looks fine.

Welded After Hot-Dip Galvanized crowd control barriers for australia

This is not a different “galvanizing chemistry,” but a finishing/cooling method: after dipping, the barrier cools naturally in air (instead of quenching).

Principle (what air-cooling affects):

Why it is often discussed: white rust

Real barrier outcome:

Air-cooling is beneficial when combined with correct storage and packing practices, especially right after galvanizing.

air cooled crowd control barriers

Process: steel strip is galvanized on a continuous line → then formed into tube → used to fabricate barriers.

Principle (why it’s cost-effective but often shorter-lived in rough outdoor service):

Real barrier outcome:

Good for budget projects or short-term/indoor use, but weld points and high-wear zones can rust sooner in outdoor hire fleets.

pre-galvanized crowd control barriers for sale

| Route / Type | Protection at welds & cut ends | Handles stacking/abrasion | Typical outdoor durability | Main risk point |

|---|---|---|---|---|

| Welded before HDG | Excellent | High | High | Needs proper vent/drain design |

| Welded after HDG | Weak unless repaired well | Medium | Medium–Low | Weld rust if repair is poor |

| Air-cooled HDG | Excellent | High | High | White rust risk depends on wet storage |

| Pre-galvanized | Weak at welds unless repaired | Medium–Low | Low–Medium | Thin coating + weld zones |

If you want Hot Dip Galvanized barriers that last in real outdoor and rental conditions, specify these items clearly:

Q1: Is “galvanized” always hot-dip galvanized?

No. Some products use pre-galv tube or thin zinc methods. The service life difference shows up at welds and wear points.

Q2: Why do welds rust first?

Because welding removes zinc locally and creates a heat-affected zone that is more corrosion-active unless the zinc protection is properly restored.

Q3: What is white rust—does it mean failure?

White rust is a zinc corrosion product caused by wet storage with poor airflow. It is often cosmetic early on, but severe cases can consume zinc and reduce coating life.

Q4: Which type is best for outdoor hire fleets?

In most real barrier use cases: welded before hot-dip galvanizing gives the most consistent long-term protection.