Garrison Fencing: Compliant with Australian and NZ Standards

- 20GP container loading: 140 kit

- 40HC container loading: 320 kit

- HS code: 7308900000

- Packing: Metal stillages

- Price: $38.99 - $109.12 per kit

- Welding: Silicon Bronze Welding & stainless steel wire welded

- MOQ: 140 kits

- Rails: 40mm x 40mm and 45mm x 45mm, etc.

- Color: Available in any colors from RAL color charts

- Description

- Production Process

- Colors

- Standard

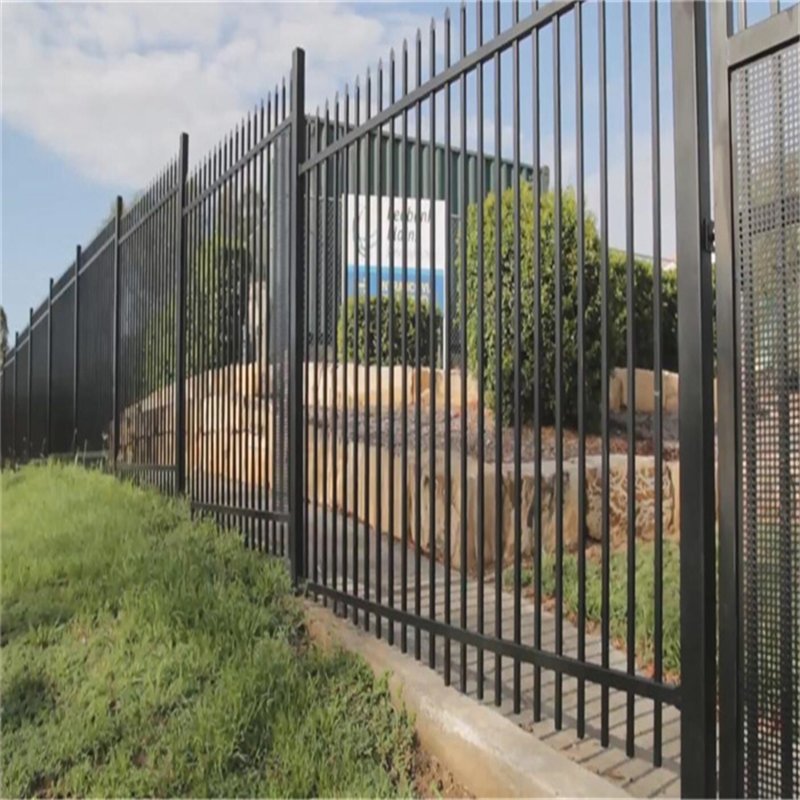

At BMP, we commit to delivering high-quality garrison fencing that meets the stringent standards of both Australia and New Zealand. We design, manufacture, and finish our products to comply with the following standards, ensuring durability, safety, and exceptional performance.we take pride in offering garrison fencing solutions that not only meet stringent Australian and New Zealand standards but also provide superior aesthetics and security features. A key aspect of our fencing is the use of black powder coating and the option of crimped spear tops or flat tops, which are both popular choices for enhancing the fence’s appearance and deterrent capabilities.

Black Powder Coating for Superior Protection and Appearance

- Durable Finish: Our garrison fences are typically finished with a high-quality black powder coating, compliant with AS 4506:2005 – Metal Finishing – Thermoset Powder Coatings. This standard ensures that the powder coating is applied correctly, resulting in excellent adhesion, hardness, and resistance to chipping, scratching, and UV degradation.

- Corrosion Resistance: The black powder coating provides an additional layer of protection over the hot-dip galvanized steel (AS/NZS 4680:2006), enhancing the fence’s ability to resist corrosion. This is particularly beneficial in harsh environmental conditions, such as coastal or industrial areas.

- Aesthetic Appeal: The sleek black finish offers a modern and professional appearance that complements a variety of architectural styles. It enhances the visual appeal of the property while maintaining a strong security presence.

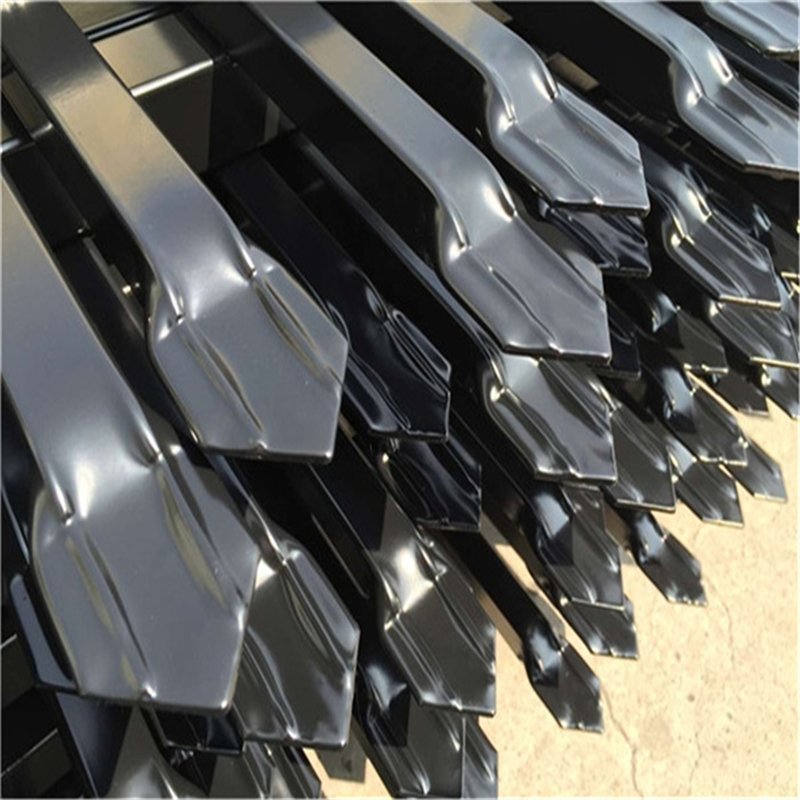

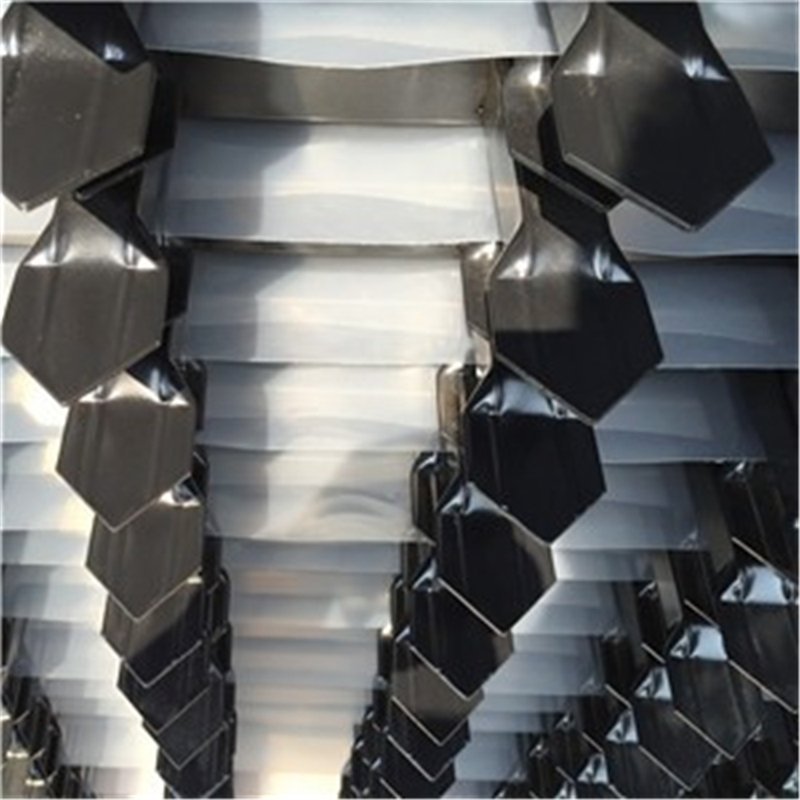

Crimped Spear Tops and Flat Tops: Customizing Your Security

We offer garrison fencing with two main top designs:

Crimped Spear Tops

Enhanced Security: The crimped spear top design features pointed pales that act as a physical deterrent against climbing and intrusion. This makes it an ideal choice for high-security areas like industrial sites, schools, and government facilities.

Visual Deterrent: The aggressive appearance of spear tops sends a clear message about the security level of the property, potentially discouraging unauthorized access.

Compliance with Standards: Our spear top fences are engineered to meet AS 4100:2020 – Steel Structures and AS/NZS 1170.2:2021 – Wind Actions, ensuring they provide both structural integrity and resistance to wind loads.

Flat Tops

Safety: Flat top garrison fencing offers a safer alternative where the risk of injury from sharp edges needs to be minimized, such as in residential areas, parks, and playgrounds.

Modern Look: The clean lines of the flat top design provide a contemporary aesthetic that can enhance the property’s curb appeal without compromising on security.

Versatility: Flat tops are suitable for various applications and can be customized with additional features like decorative elements or branding.

| Flat top | Crimped Spear |

|

|

Specifications

Cheapest Garrison Fencing Specifications

| Fence Height (mm) | Fence Width (mm) | Upright Pale Thickness (mm) (25mm×25mm) | Upright Spacing (mm) | Quantity: Pale (pcs) | Cross Rails (mm) | Post Height (mm) | Square Post Section (mm) |

|---|---|---|---|---|---|---|---|

| 1800 | 2400 | 1.0 (25mm×25mm) | 101 | 18 | 40×40×1.2mm | 2400mm | 65×65×3.0 |

| 2100 | 2400 | 1.0 (25mm×25mm) | 101 | 18 | 40×40×1.2mm | 2700mm | 65×65×3.0 |

| 2400 | 2400 | 1.0 (25mm×25mm) | 101 | 18 | 40×40×1.2mm | 3000mm | 65×65×3.0 |

| 2700 | 2400 | 1.0 (25mm×25mm) | 101 | 18 | 40×40×1.2mm | 3300mm | 75×75×3.0 |

| 3000 | 2400 | 1.0 (25mm×25mm) | 101 | 18 | 40×40×1.2mm | 3600mm | 75×75×3.0 |

Standard Garrison Fencing Specifications

| Fence Height (mm) | Fence Width (mm) | Upright Pale Thickness (mm) (25mm×25mm) | Upright Spacing (mm) | Quantity: Pale (pcs) | Cross Rails (mm) | Post Height (mm) | Square Post Section (mm) |

|---|---|---|---|---|---|---|---|

| 1800 | 2400 | 1.2 (25mm×25mm) | 101 | 18 | 40×40×1.5mm | 2400mm | 65×65×3.0 |

| 2100 | 2400 | 1.2 (25mm×25mm) | 101 | 18 | 40×40×1.5mm | 2700mm | 65×65×3.0 |

| 2400 | 2400 | 1.2 (25mm×25mm) | 101 | 18 | 40×40×1.5mm | 3000mm | 65×65×3.0 |

| 2700 | 2400 | 1.2 (25mm×25mm) | 101 | 18 | 40×40×1.5mm | 3300mm | 75×75×3.0 |

| 3000 | 2400 | 1.2(25mm×25mm) | 101 | 18 | 40×40×1.5mm | 3600mm | 75×75×3.0 |

Heavy duty Garrison Fencing Specifications

| Fence Height (mm) | Fence Width (mm) | Upright Pale Thickness (mm) (25mm×25mm) | Upright Spacing (mm) | Quantity: Pale (pcs) | Cross Rails (mm) | Post Height (mm) | Square Post Section (mm) |

|---|---|---|---|---|---|---|---|

| 1800 | 2400 | 1.6 (25mm×25mm) | 101 | 18 | 40×40×2.0mm | 2400mm | 65×65×3.0 |

| 2100 | 2400 | 1.6 (25mm×25mm) | 101 | 18 | 40×40×2.0mm | 2700mm | 65×65×3.0 |

| 2400 | 2400 | 1.6 (25mm×25mm) | 101 | 18 | 40×40×2.0mm | 3000mm | 65×65×3.0 |

| 2700 | 2400 | 1.6 (25mm×25mm) | 101 | 18 | 40×40×2.0mm | 3300mm | 75×75×3.0 |

| 3000 | 2400 | 1.6(25mm×25mm) | 101 | 18 | 40×40×2.0mm | 3600mm | 75×75×3.0 |

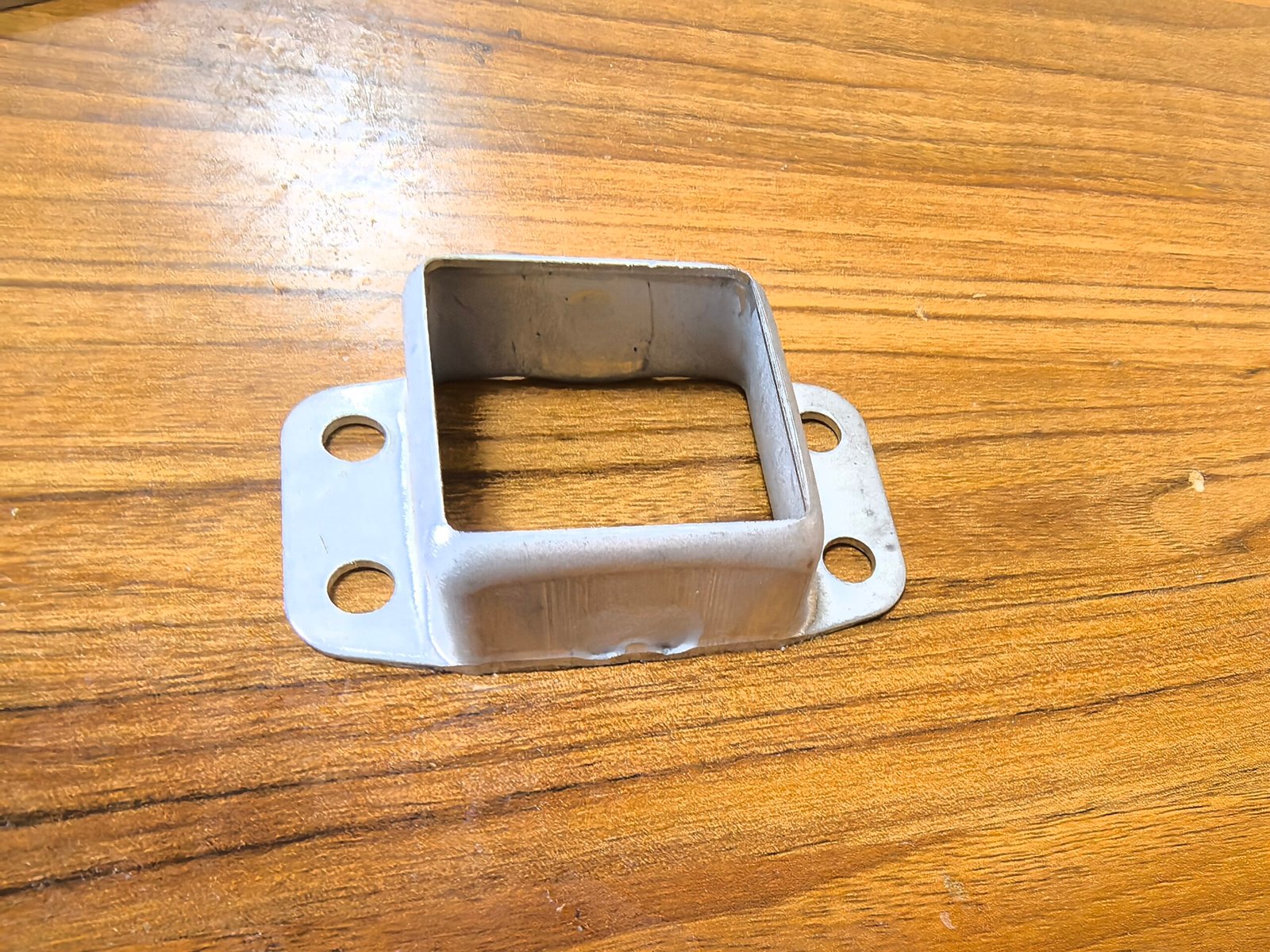

Garrison Fencing Bracket 40mmx40mm Specifications

| Specification | Details |

|---|---|

| Length | 84mm |

| Width | 48mm |

| Height | 40mm |

| Wall Thickness | 3.00mm – 4.00mm |

| Included Screws | 4 Tex Screws |

| Bracket work with garrison fencing panels | Polyester powder coated garrison fencing come with 4 tex screws |

|

|

| Black Powder coated Minimum 80 microns | Aluminum Made Garrison Fencing brackets |

|

|

Garrsion Fencing Bracket -A

| Specification | Details |

|---|---|

| Length | 90mm |

| Height | 25mm |

| Wall Thickness | 2.00mm |

| Insert Hole for Tex Screw | 6mm x 2 |

| Finish | Hot dipped galvanized, polyester powder coated available |

|

|

Garrsion Fencing Bracket -B

| Specification | Details |

|---|---|

| Length | 90mm |

| Height | 35mm |

| Wall Thickness | 2.00mm |

| Insert Hole for Tex Screw | 6mm x 2 |

| Finish | Hot dipped galvanized, polyester powder coated available |

|

|

Garrsion Fencing Bracket -C

| Specification | Details |

|---|---|

| Length | 75mm |

| Height | 25mm |

| Wall Thickness | 2.00mm |

| Insert Hole for Tex Screw | 6mm x 2 |

| Finish | Hot dipped galvanized, polyester powder coated available |

|

|

Garrsion Fencing Bracket -D

| Specification | Details |

|---|---|

| Length | 75mm |

| Height | 25mm |

| Wall Thickness | 2.00mm |

| Insert Hole for Tex Screw | 6mm x 4 |

| Finish | Hot dipped galvanized, polyester powder coated available |

|

|

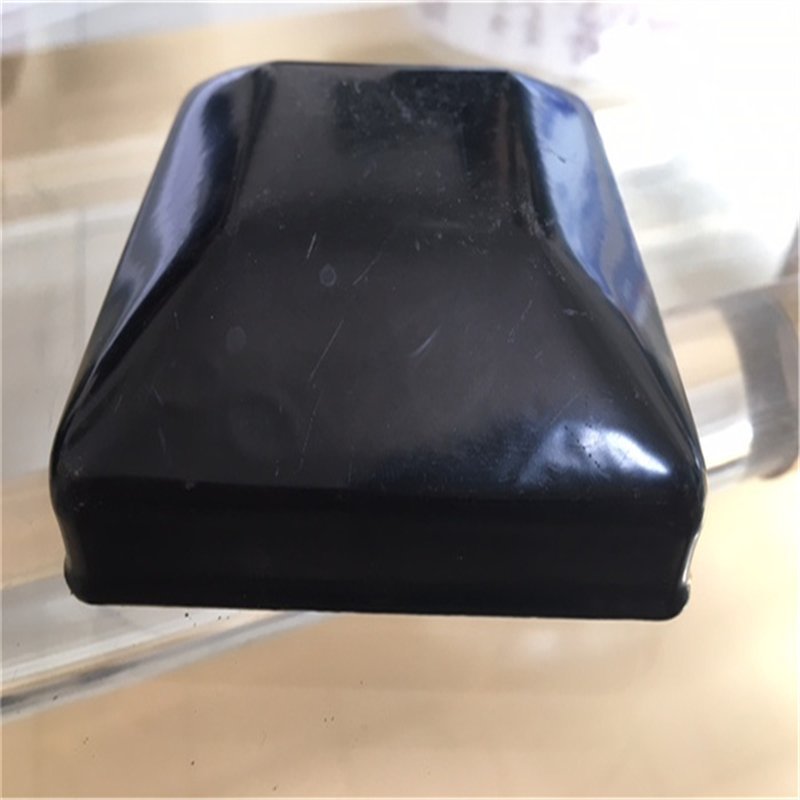

Garrison Fencing Post Caps

| Specification | Details |

|---|---|

| Cap Options | UV Treated Plastic Caps, Steel Caps |

| Suitability | Fits 65mm x 65mm Fence Posts |

|

|

| Plastic Caps | Steel Caps |

Tips for Choosing Between Steel Caps and Plastic Caps:

- Durability:

- Steel Caps: Offer superior durability and withstand impact and harsh weather conditions better than plastic caps.

- Plastic Caps: UV-treated plastic caps resist fading and cracking in sunlight but are generally less durable than steel in high-impact situations.

- Corrosion Resistance:

- Steel Caps: Ensure they are galvanized or coated to prevent rust and corrosion, especially in coastal or humid environments.

- Plastic Caps: Naturally immune to rust, making them a good choice in corrosive environments.

- Aesthetic Appeal:

- Steel Caps: Provide a sleek, modern, and industrial look, suitable for high-security or commercial fencing projects.

- Plastic Caps: Available in a variety of colors and finishes, offering more design flexibility for residential or decorative projects.

- Strength:

- Steel Caps: Provide additional strength, especially for fencing in high-security or heavy-duty applications.

- Plastic Caps: More lightweight but still sufficient for standard residential or light commercial use.

- Cost-Effectiveness:

- Steel Caps: Higher initial cost but lower long-term maintenance due to their strength and durability.

- Plastic Caps: Lower upfront cost and still durable for standard use, making them cost-effective for residential projects.

Why Garrison Fencing Uses Stainless Steel Wire Welding or Silicon Bronze Welding

In the fabrication of garrison fencing, the choice of welding method and filler material is crucial to ensure the fence’s structural integrity, durability, and corrosion resistance. Two commonly used welding materials are stainless steel wire and silicon bronze wire. Both have specific advantages, especially when working with galvanized steel, which is the standard material for garrison fencing due to its corrosion-resistant properties.

Challenges with Welding Galvanized Steel

Before diving into why we use these materials, it’s important to understand the challenges that come with welding galvanized steel:

- Zinc Coating Vaporization: The zinc coating on galvanized steel can vaporize at high temperatures during welding, leading to the loss of corrosion protection around the weld area and producing toxic fumes harmful to welders.

- Weld Quality: The presence of zinc can lead to porosity and inclusions in the weld, compromising its strength and integrity.

- Heat Distortion: High heat input can cause warping or distortion of steel components, affecting the fence’s appearance and structural alignment.

|

|

|

|

Advantages of Silicon Bronze Welding

Silicon bronze welding involves using a copper-based filler wire containing silicon. This method is often referred to as MIG brazing.

1. Lower Melting Point

- Reduced Heat Input: Silicon bronze melts at a lower temperature (~980°C) compared to steel (~1500°C). This means less heat is required, minimizing the risk of distorting the steel and preserving the zinc coating.

2. Preservation of Zinc Coating

- Minimal Zinc Burn-off: Lower welding temperatures reduce the vaporization of the zinc coating, maintaining corrosion resistance near the welds.

3. Corrosion Resistance

- Enhanced Protection: Silicon bronze is highly resistant to corrosion, adding an extra layer of protection to the welded joints.

4. Aesthetic Appeal

- Clean Welds: Produces smooth and visually appealing welds with minimal spatter, which is beneficial for fences where appearance is important.

Advantages of Stainless Steel Wire Welding

Stainless steel wire welding uses stainless steel filler material in the welding process.

1. High Strength and Durability

- Robust Welds: Stainless steel provides strong, durable welds capable of withstanding mechanical stresses.

2. Corrosion Resistance

- Resilient Joints: Stainless steel is inherently corrosion-resistant, ensuring the weld joints remain rust-free even if the zinc coating is compromised during welding.

3. Compatibility with Galvanized Steel

- Effective Joining: With proper technique, stainless steel wire can effectively weld galvanized steel, although managing the different properties of the metals requires care.

Why These Methods are Preferred

Minimizing Damage to Zinc Coating

- Silicon Bronze: Its lower heat input means less zinc vaporization, preserving the galvanized coating’s integrity.

- Stainless Steel: While it operates at higher temperatures than silicon bronze, experienced welders can minimize zinc damage through controlled techniques.

Reducing Health Hazards

- Fewer Toxic Fumes: Less zinc vaporization means fewer harmful fumes, creating a safer working environment for welders.

Improving Weld Quality

- Silicon Bronze: Produces cleaner welds with less porosity.

- Stainless Steel: Offers strong, reliable welds when done correctly.

Applications in Garrison Fencing

- Silicon Bronze Welding is ideal when:

- Preservation of the zinc coating is a priority.

- Working with thinner steel sections prone to heat distortion.

- A high-quality aesthetic finish is desired.

- Stainless Steel Wire Welding is suitable when:

- Additional strength at the weld joint is required.

- The added corrosion resistance of stainless steel is beneficial.

- Welding thicker steel components where heat distortion is less of a concern.

Welding way of garrion fencing

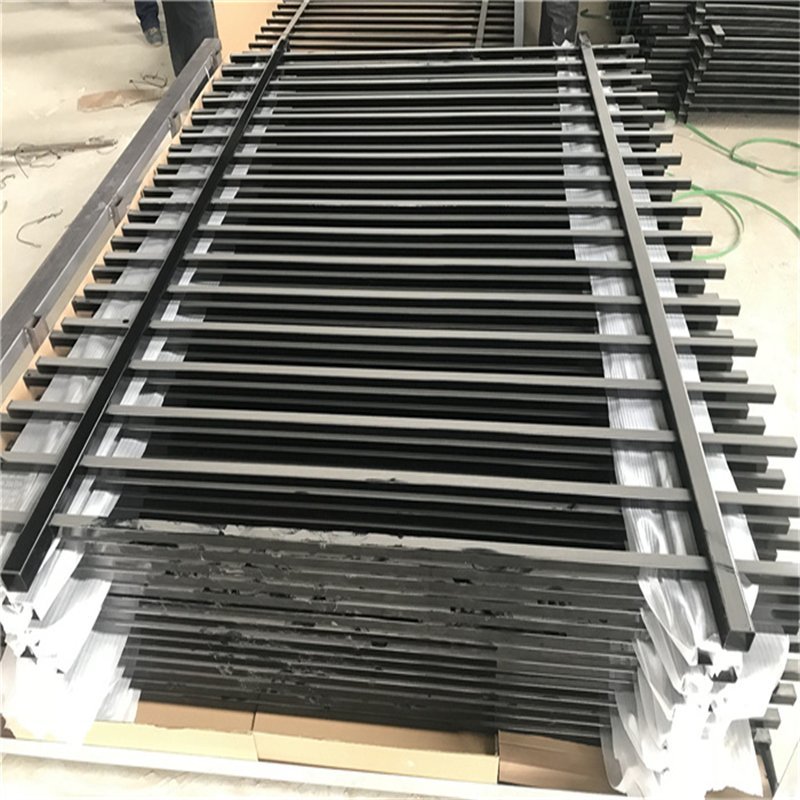

Our garrison fencing offers two primary construction methods to suit different needs and preferences: face-welded and punched rails with welded pales. Both options provide excellent strength and durability, but each has distinct benefits, depending on the application and aesthetic requirements.

| Face welded | Punched Rails welded |

|

|

Face-Welded Garrison Fencing

In face-welded garrison fencing, the upright pales are directly welded to the front face of the horizontal rails. This method provides a seamless and sleek look, with the welding beads located on the front and back of the fence for added strength.

- Strength & Stability: Face-welding offers increased rigidity, as each pale is directly welded onto the rails, creating a solid structure that resists impact and pressure.

- Sleek Aesthetic: The face-welded design gives the fence a smooth, uninterrupted appearance, making it a popular choice for applications where aesthetics are important, such as commercial properties, parks, and residential areas.

- Corrosion Resistance: When combined with hot-dip galvanization, face-welded garrison fencing offers superior protection against rust and corrosion, ensuring the fence remains strong and visually appealing over time.

Punched Rails with Welded Pales

In this design, the horizontal rails are punched with evenly spaced holes through which the upright pales are inserted before being welded in place. This construction method creates a more integrated connection between the rails and pales.

- Enhanced Durability: By punching holes in the rails and inserting the pales, this method ensures a strong mechanical connection. The welded pales provide additional strength, making this type of garrison fencing ideal for high-security applications where increased robustness is required.

- Neater Appearance: The welded joints in this design are often less visible, providing a cleaner and more refined finish. This makes it suitable for locations where both security and appearance are critical, such as schools, government buildings, and industrial sites.

- Customization Options: With punched rails, it is easier to accommodate different spacing and pale sizes, allowing more flexibility in design. This can be particularly useful for projects requiring specific spacing for security or aesthetic purposes.

|

|

|

|

Benefits of Both Types of Garrison Fencing

Regardless of whether you choose face-welded or punched rails with welded pales, both types of garrison fencing share common benefits:

- Security: Both options provide a high level of security due to the strength of their construction and the spacing of the pales, which makes it difficult to climb or breach.

- Customization: Available in various heights, widths, and pale thicknesses, you can customize either type to meet your specific needs. Additionally, both methods are compatible with powder coating or hot-dip galvanization, ensuring longevity and resistance to weather.

- Low Maintenance: With durable finishes and sturdy construction, both face-welded and punched rail garrison fences require minimal maintenance, even in harsh environments.

Applications

- Face-Welded Garrison Fencing: Ideal for residential areas, commercial properties, public parks, and schools where a clean, modern appearance is desired along with solid security.

- Punched Rails with Welded Pales: Suitable for high-security areas such as industrial complexes, warehouses, government facilities, and other critical infrastructure that requires a more robust fence.

Why Choose BMP for Garrison Fencing?

- Compliance with Standards: All of our garrison fencing, whether face-welded or punched rails, complies with Australian and New Zealand standards, ensuring safety, quality, and durability.

- Custom Solutions: We offer a range of customization options to ensure the fencing perfectly meets your specific requirements, from pale spacing to finish options.

- Expert Craftsmanship: Our skilled welders and fabricators ensure that every weld is secure, strong, and built to last, whether you choose face-welded or punched rail designs.

Whether you need sleek and modern face-welded garrison fencing or heavy-duty punched rails with welded pales, we provide high-quality fencing solutions designed to meet your security and aesthetic needs. Contact us today to find out more about which option best suits your project.

How to Properly Pack Garrison Fencing Panels, Posts, and Accessories to Minimize Damage During Transportation

Proper packaging is essential to ensure that garrison fencing panels, posts, and accessories arrive at their destination without damage. By following these detailed guidelines, you can significantly reduce the risk of scratches, dents, and other transportation-related damages.

Bracket packed in paper made cartons |

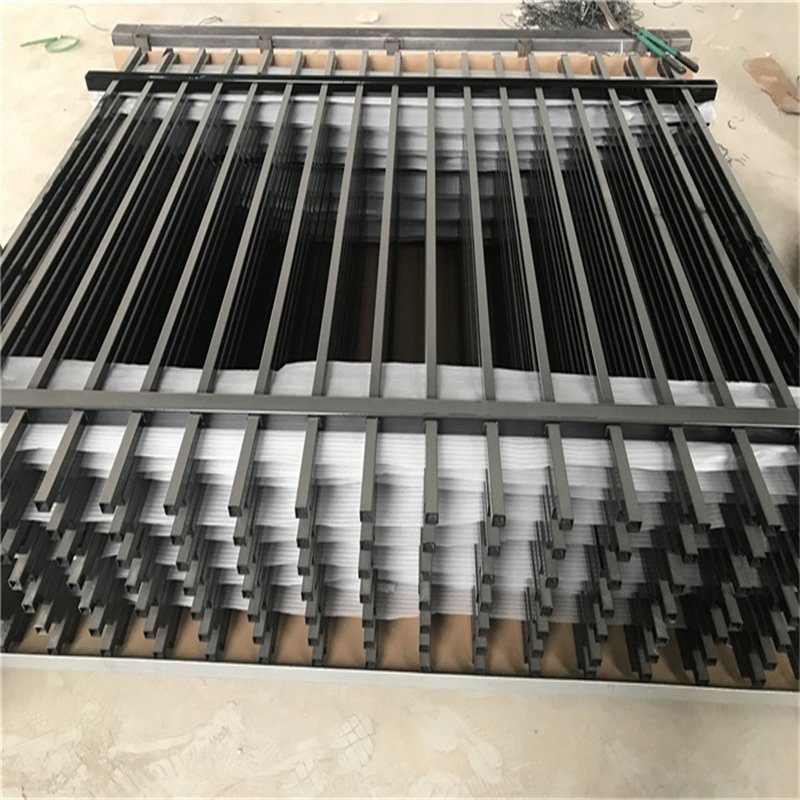

Garrison Fence panels packed in metal stillaged wrapped with plastic film |

Garrison Fencing Post wrapped with bubble plastic film avoid cracked poyester layers |

Each fence panels with plastic film |

Packing Garrison Fencing Panels

To protect fencing panels during transit, adhere to the following steps:

- Protect the Base: Place bubble wrap at the bottom of the pallet. This prevents the bottom fence panel from making direct contact with the metal pallet, reducing the risk of scratches or abrasions.

- Reinforce the Pallet: Attach four metal corners to the pallet. This strengthens the structure and maintains its integrity throughout transportation.

- Distribute Tension Evenly: Insert a metal plate beneath the plastic banding straps. This ensures that the force from the straps is evenly distributed and prevents them from cutting into the panels.

- Shield the Top: Place a wooden plate on top of the stacked panels. This protects them from any weight applied from stacked pallets above during transit.

|

|

|

|

Packing Garrison Fencing Posts

When preparing fencing posts for shipment, follow these precautions:

- Base Protection: Line the bottom of the pallet with bubble wrap to prevent direct contact between the posts and the metal pallet.

- Pallet Reinforcement: Install four metal corners on the pallet to enhance strength and prevent shifting or collapse during transportation.

- Prevent Direct Pressure: Place a metal plate under the plastic banding straps to avoid excessive force on the posts, which could lead to bending or other damage.

- Top Protection: Add a wooden plate on top of the posts to safeguard them from the weight of any additional pallets stacked above.

Packing Garrison Fencing Accessories

To securely pack accessories and ensure they remain in optimal condition:

- Organize and Protect: Place all accessories into individual plastic bags. This keeps them organized and shields them from scratches, moisture, and other potential damages.

- Secondary Packaging: Pack the plastic bags into sturdy carton boxes. This provides an additional layer of protection against impacts and simplifies handling and stacking.

Conclusion

At BMP, our dedication to excellence is reflected in every aspect of our garrison fencing solutions. By strictly adhering to both Australian and New Zealand standards, we ensure that our products not only meet but exceed industry expectations for durability, safety, and performance.

Our comprehensive range of garrison fencing—available in Cheapest, Standard, and Heavy-Duty specifications—provides versatile options tailored to meet various security needs and budgets without compromising on quality. The meticulous selection of materials, such as hot-dip galvanized steel and optional powder coatings, guarantees enhanced corrosion resistance and longevity, even in the most challenging environments.

Production Process of Garrison Fencing

The production of garrison fencing involves a meticulous 8-step process designed to ensure high quality, durability, and aesthetic appeal. Below is a clear and logical outline of each step:

Raw Material Inspection

- Objective: Ensure the structural integrity and durability of the fence by verifying the quality of raw materials.

- Process: Specialists examine the outer diameter and wall thickness of steel tubes to confirm they align with detailed product specifications.

Material Cutting Garrison Fencing

- Objective: Achieve precise lengths required for the fence components.

- Process: Advanced cutting technology is used to cut the tubes according to design requirements, ensuring clean and accurate cuts for uniformity.

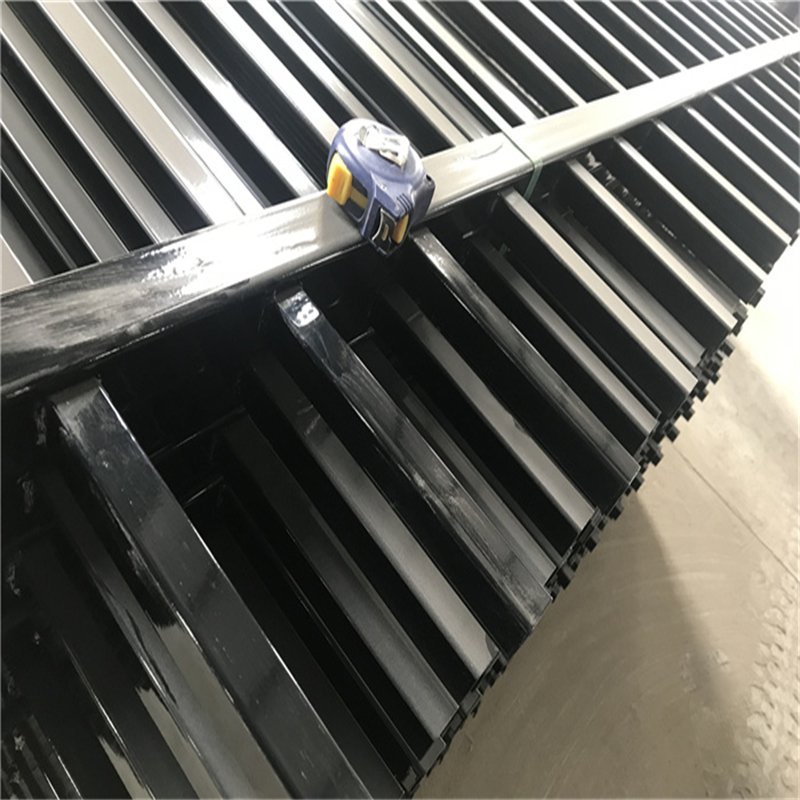

Flattening the Vertical Tubes

- Objective: Increase the contact area for welding, leading to stronger joints.

- Process: Vertical tubes are flattened using state-of-the-art machinery without compromising the metal’s integrity, preparing them for assembly.

Welding

Objective: Assemble the fence components securely.

Process:

- Garrison Fence Welding: Vertical pipes are directly welded to the surface of the horizontal pipes.

- Techniques Used: Double-sided full welding, spot welding, and circumferential welding, chosen based on the specific part of the fence to enhance structural strength.

Sandblasting

- Objective: Clean and prepare the metal surface for better paint adherence.

- Process: Sandblasting removes oxidation and impurities, creating a clean, rough surface ideal for subsequent chemical treatments and painting.

Phosphating for Garrison Fencing

- Objective: Protect the metal against rust and improve paint adhesion.

- Process: A chemical phosphating process forms a protective layer on the cleaned metal surfaces, enhancing longevity and durability.

Painting

Objective: Provide aesthetic enhancement and a protective barrier against environmental elements.

Process: We apply high-quality, eco-friendly paints evenly in a controlled area using methods like electrophoresis or spraying. The process ensures even coverage and optimal drying for a flawless finish.

Packaging

Objective: Ensure the product’s safety during transportation.

Process:

- Horizontal beams are wrapped with robust shrink wrap, placed on iron pallets, and secured with protective corner boards and strapping bands.

- Vertical posts are individually wrapped in plastic and palletized.

- Plywood or metal frames separate pallets to prevent damage from direct contact.

Production Considerations Garrison Fencing

Material Selection and Processing:

- Use of high-quality steel with rigorous testing for tensile strength and corrosion resistance.

- Proper pre-treatment, such as rust removal and preheating, before production to ensure quality in welding and coating.

Welding Techniques:

- Utilization of automated welding technology for uniform and strong welds.

- Precise adjustment of welding parameters (current and voltage) based on material characteristics.

Garrison Fencing Coating Process:

- Application of high-adhesion, anti-corrosion paints to ensure durability.

- Even application through methods like electrophoresis or spraying to withstand various weather conditions without fading or rusting.

Quality Control:

- Strict quality checkpoints at every production stage.

- Professional quality tests from raw materials to finished products to ensure compliance with international safety standards.

Applications of Garrison Fencing

Garrison fencing works well in places where you need both security and a nice look. You can find it around government buildings, businesses, schools, and factories. It also fits in areas that need strong protection without looking too harsh, like apartment complexes, parks, and sports fields.

Benefits of Garrison Fencing

Garrison fencing is strong and lasts a long time because we use high-quality steel. It keeps unwanted people out and protects your property. The simple, flat design looks modern and suits many settings. Our special coating stops rust and weather damage, so the fence stays good with little maintenance. You can also customize garrison fences with different sizes, colors, and finishes to fit your needs.

Conclusion

Making garrison fencing involves many careful steps to ensure it is precise, durable, and high quality. We start by checking the raw materials and continue through cutting, welding, painting, and packaging. Each step helps us create a fence that is safe and looks great. We follow strict production rules and quality checks to make sure our fences are strong, long-lasting, and good for the environment.

Garrison Fencing Colors: Exploring RAL Color Options

When it comes to selecting garrison fencing, color plays a crucial role in both aesthetics and functionality. The right color can enhance the visual appeal of a property while providing protection against environmental factors. One of the most popular color standards for fencing is the RAL color system. This article delves into the available RAL colors for garrison fencing, their benefits, and how to choose the perfect shade for your needs.

What Are RAL Colors?

RAL is a color matching system used in Europe that defines colors for paint, coatings, and plastics. Established in 1927, the RAL system ensures consistency and accuracy in color application across various industries. RAL colors are widely recognized for their reliability, making them a preferred choice for garrison fencing.

Available RAL Colors for Garrison Fencing

Garrison fencing can be customized with a wide range of RAL colors to match any design preference or property requirement. Here are some popular RAL colors used for garrison fencing:

1. RAL 7016 – Anthracite Grey

- Description: A deep, sophisticated grey that offers a modern and sleek look.

- Best For: Contemporary buildings, commercial properties, and urban settings.

2. RAL 9005 – Jet Black

- Description: A pure, intense black that provides a bold and elegant appearance.

- Best For: High-security areas, residential properties, and areas requiring a strong visual statement.

3. RAL 7035 – Light Grey

- Description: A light, neutral grey that blends seamlessly with various environments.

- Best For: Residential complexes, parks, and areas where subtlety is preferred.

4. RAL 5010 – Gentian Blue

- Description: A vibrant blue that adds a touch of color without being overpowering.

- Best For: Schools, recreational facilities, and community centers.

5. RAL 3020 – Traffic Red Garrison Fencing

- Description: A bright red that stands out and catches attention.

- Best For: Industrial sites, warning areas, and places needing high visibility.

6. RAL 6005 – Moss Green

- Description: A rich green that complements natural surroundings.

- Best For: Parks, gardens, and properties aiming for an eco-friendly look.

7. RAL 8003 – Clay Brown

- Description: A warm brown that provides a natural and earthy feel.

- Best For: Residential areas, rural properties, and traditional settings.

8. RAL 5015 – Sky Blue

- Description: A soft blue that offers a calming and pleasant appearance.

- Best For: Schools, hospitals, and public spaces.

Benefits of Choosing RAL Colors for Garrison Fencing

1. Consistency and Accuracy

The RAL system ensures that the color you choose matches exactly what you see in catalogs and samples. This consistency is crucial for maintaining the desired look across large fencing projects.

2. Wide Range of Options

With over 200 RAL colors available, you have the flexibility to choose a shade that perfectly complements your property’s design and surroundings.

3. Durability and Fade Resistance

RAL-certified paints are formulated to withstand harsh weather conditions. They resist fading, ensuring your garrison fence maintains its color and appearance over time.

4. Enhanced Aesthetic Appeal

Choosing the right color can significantly enhance the visual appeal of your property. Whether you prefer a bold statement or a subtle blend, RAL colors offer the perfect shade for any aesthetic preference.

5. Increased Property Value

A well-colored garrison fence can boost the overall appearance of your property, potentially increasing its market value and appeal to prospective buyers or tenants.

How to Select the Right RAL Color for Your Garrison Fence

1. Consider the Surroundings

Choose a color that complements the existing environment. For urban settings, neutral or dark colors like RAL 7016 or RAL 9005 work well. In natural settings, greens and earthy tones like RAL 6005 or RAL 8003 are ideal.

2. Reflect Your Style

Your personal or brand style should influence your color choice. Modern styles may favor sleek greys and blacks, while traditional styles might prefer warmer browns and muted greens.

3. Think About Maintenance

Darker colors like black may show dirt and scratches more easily, requiring more frequent maintenance. Lighter colors might hide imperfections better but could fade faster under intense sunlight.

4. Evaluate Security Needs

Brighter colors like RAL 3020 can act as a visual deterrent by attracting attention, while darker colors provide a more discreet and intimidating barrier.

5. Test Samples

Before finalizing your decision, apply small samples of your chosen RAL colors to a section of the fence. This allows you to see how the color looks in different lighting conditions and ensures it meets your expectations.

Conclusion

Choosing the right color for your garrison fencing is essential for both aesthetic appeal and functional performance. The RAL color system offers a wide array of reliable and vibrant colors that cater to diverse preferences and requirements. By selecting the appropriate RAL color, you can enhance the beauty, security, and longevity of your garrison fence, ensuring it complements your property while providing robust protection.

Whether you opt for the modern elegance of RAL 7016 Anthracite Grey or the bold statement of RAL 9005 Jet Black, RAL colors provide the flexibility and quality needed to create a stunning and durable fencing solution. Embrace the variety and precision of RAL colors to achieve the perfect balance of style and security for your garrison fencing.

Standard Complied

Garrison fencing serves as a dependable and sturdy barrier for securing various types of properties across Australia and New Zealand. Whether it’s safeguarding government buildings, commercial establishments, schools, or residential areas, our garrison fences provide both security and aesthetic appeal. To ensure that our fencing solutions meet the highest standards of quality and performance, we adhere to rigorous Australian and New Zealand standards.

Australian Standards

- AS/NZS 4680:2006 – Hot-Dip Galvanized (Zinc) Coatings on Fabricated Ferrous Articles

- Corrosion Protection: All our steel fencing components undergo hot-dip galvanization in accordance with AS/NZS 4680:2006. This process provides essential protection against rust and corrosion, significantly enhancing the longevity of our fences, especially in coastal and humid environments.

- AS 4100:2020 – Steel Structures

- Structural Integrity: We adhere to AS 4100:2020 in the design, fabrication, and erection of our steel garrison fencing. This ensures that our products meet the necessary structural integrity and safety requirements, providing you with a robust and reliable fencing solution.

- AS/NZS 1170.2:2021 – Structural Design Actions Part 2: Wind Actions

- Wind Load Resistance: Our fencing systems are engineered to withstand wind pressures specific to various Australian locations by complying with AS/NZS 1170.2:2021. This standard ensures our fences maintain their integrity under challenging weather conditions.

- AS 4506:2005 – Metal Finishing – Thermoset Powder Coatings

- Powder Coating Quality: For fences requiring a powder-coated finish, we comply with AS 4506:2005. This guarantees that the thermoset powder coatings are applied correctly, offering excellent adhesion, hardness, and resistance to chipping and UV degradation.

New Zealand Standards

- AS/NZS 4680:2006 – Hot-Dip Galvanized (Zinc) Coatings on Fabricated Ferrous Articles

- Corrosion Protection: Similar to our Australian operations, we hot-dip galvanize all steel components for the New Zealand market in line with AS/NZS 4680:2006, safeguarding against corrosion and extending the life of our fencing products.

- NZS 3404.1:2009 – Steel Structures Standard Part 1: Materials, Fabrication, and Construction

- Structural Integrity: Our garrison fencing complies with NZS 3404.1:2009, ensuring that materials, fabrication, and construction methods meet New Zealand’s standards for safety and structural soundness.

- AS/NZS 1170.2:2021 – Structural Design Actions Part 2: Wind Actions

- Wind Load Resistance: We utilize AS/NZS 1170.2:2021 to design fences capable of withstanding local wind conditions in New Zealand, ensuring stability and durability throughout their service life.

Key Benefits of Our Compliant Garrison Fencing

- Enhanced Durability: Compliance with hot-dip galvanizing standards provides robust protection against environmental factors, reducing maintenance costs and increasing lifespan.

- Safety Assurance: Adhering to structural standards guarantees that our fencing systems are safe for various applications, including residential, commercial, and industrial settings.

- Weather Resilience: By meeting wind load resistance standards, our fences remain secure and intact even in high-wind areas, providing peace of mind.

- Superior Finish: Our powder-coated fences not only offer an attractive appearance but also enhanced protection against wear and tear, thanks to compliance with coating standards.

Commitment to Quality

By strictly following these Australian and New Zealand standards, BMP ensures that our garrison fencing products are of the highest quality. Our dedication to compliance demonstrates our commitment to providing customers with fencing solutions that are safe, durable, and built to withstand the test of time.

For more information or to discuss your specific fencing needs, please contact our team. We are here to assist you in selecting the perfect fencing solution that complies with all relevant standards and exceeds your expectations.

Garrison Fencing