- Description

What is Galvanized Crowd Control Barriers?

Galvanized crowd control barriers are durable solutions designed to manage large crowds and control access at events, construction sites, protests, and public gatherings. These barriers feature a galvanized steel finish that protects them from rust and corrosion, ensuring long-lasting performance in outdoor environments.

Benefits of Galvanized Crowd Control Barriers

These barriers are known for their strong, weather-resistant construction, making them ideal for both temporary and permanent use. The lightweight design makes them easy to transport and install. They interlock seamlessly, forming a secure, stable line to manage and control crowds effectively.

The base options, such as flat or bridge-style feet, provide excellent stability on various surfaces. These feet help prevent tipping, ensuring the barriers remain secure even during high-traffic events or uneven ground conditions.

|

|

|

|

How to Choose Between Galvanized and Powder-Coated Crowd Control Barriers

When selecting between galvanized and powder-coated crowd control barriers, it is essential to evaluate your specific needs, including environmental conditions, aesthetics, durability, and budget. Each type offers distinct advantages for different use cases.

|

|

|

|

1. Environmental Conditions and Corrosion Resistance

- Galvanized Barriers:

- Hot-dipped galvanized barriers provide superior corrosion resistance, making them ideal for long-term outdoor use, especially in harsh or coastal environments.

- Pre-galvanized barriers offer moderate protection and are suitable for short-term outdoor events or indoor applications.

- Powder-Coated Barriers:

- These barriers are better suited for environments with less exposure to moisture. While powder coating provides some corrosion resistance, it is not as robust as hot-dip galvanization.

Choose galvanized barriers if your application involves frequent outdoor exposure to rain, humidity, or coastal environments

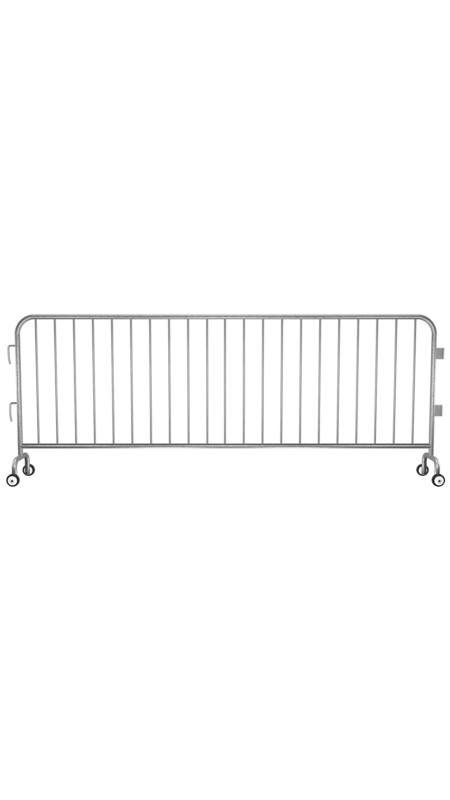

Feet Option

2. Aesthetic Appeal and Visibility

- Powder-Coated Barriers:

- Available in bright colors like yellow and orange, enhancing visibility and safety at events or construction sites.

- Ideal for public-facing applications where color consistency and aesthetics are important.

- Galvanized Barriers:

- Typically have a silver metallic finish that might look industrial. Suitable where aesthetics are less important, such as construction zones.

Choose powder-coated barriers for high-visibility applications like events, public gatherings, or roadwork where the color plays a key role in safety

3. Durability and Lifespan

- Galvanized Barriers:

- Particularly hot-dip galvanized barriers offer better durability, with resistance to scratches, rust, and wear.

- They are suitable for long-term installations where barriers may be exposed to heavy use or harsh environments.

- Powder-Coated Barriers:

- Powder coating resists chipping and fading, but if the coating gets damaged, the underlying steel can corrode.

- Suitable for medium-duty applications where the barrier will not experience extreme environmental exposure.

4. Cost and Budget

- Galvanized Barriers:

- Higher initial cost due to the hot-dip galvanization process but lower maintenance over time.

- A good choice for long-term investments with reduced replacement needs.

- Powder-Coated Barriers:

- Generally less expensive than galvanized barriers, but they may require more maintenance or replacement if used outdoors in harsh conditions.

Choose powder-coated barriers for short-term or budget-friendly projects where aesthetics and visibility are key priorities, and galvanized barriers for long-term investments

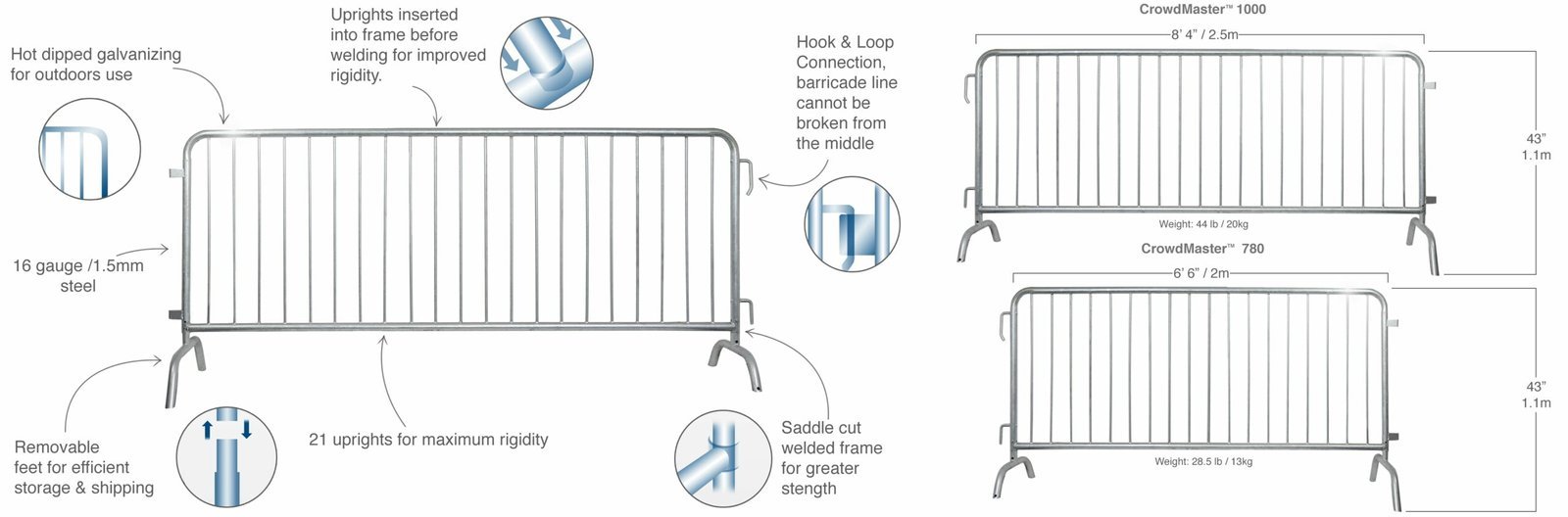

Key Features:

- Material: High-quality galvanized steel for corrosion resistance

- Design: Interlocking hook and loop system for stability

- Feet Options: Flat feet for stable surfaces or bridge feet for uneven ground

- Applications: Events, construction sites, public gatherings, and roadwork

- Durability: Weatherproof, resistant to rust and outdoor conditions

- Portability: Lightweight for easy transport and quick installation

Types of Galvanized Crowd Control Barriers

Crowd control barriers come in several types, each suited to different environments and requirements. Among them, the key difference lies in their material finish and construction method. Let’s explore the main types, focusing on their features, durability, and application.

|

|

|

|

1. Pre-Galvanized then Cold Zinc Painted Barriers

These barriers receive an initial galvanization during the steel manufacturing process (pre-galvanized). Afterward, they are coated with a cold zinc paint to further protect them from corrosion.

Features:

Lightweight yet durable.

Additional cold zinc paint provides a smooth finish.

Suitable for short-term outdoor use, especially in moderate weather.

Applications:

Indoor events, festivals, or short-term outdoor events.

Areas requiring quick installations and removals.

Limitations:

Less corrosion resistance compared to fully hot-dip galvanized barriers.

Not ideal for prolonged exposure to harsh conditions.

2. Hot-Dipped Galvanized Crowd Control Barriers

These barriers undergo a hot-dip galvanizing process, where the steel is fully immersed in molten zinc. This coating creates a thick, durable layer that resists corrosion, even in challenging environments.

Features:

Maximum protection against rust and corrosion.

Highly durable with a long lifespan, even in extreme weather.

Requires minimal maintenance.

Applications:

Construction sites, outdoor concerts, airports, and traffic control.

Areas with high exposure to rain, snow, or saltwater.

Ideal for long-term installations.

Advantages:

Performs well in harsh climates and over long periods.

Trusted for high-security events and construction areas.

3. Powder-Coated Barriers over Galvanized Steel

These barriers have a galvanized steel core and are coated with a layer of powder paint. This additional coating provides both aesthetic appeal and extra protection against corrosion.

Features:

Available in various colors for visibility and branding.

Corrosion-resistant, with added protection from wear and tear.

Smooth, non-toxic finish.

Applications:

Sporting events, marathons, parades, and public spaces requiring visible barriers.

Areas with both safety and visual appeal in mind.

Galvanized crowd control barriers Specifications

| Specification | Details |

|---|---|

| Height | 1100mm |

| Length | 2000mm (6.5 ft) or 2500mm (8 ft) |

| Weight | 13 kg (2000mm) / 20 kg (2500mm) |

| Frame Material | 38mm diameter, 16-gauge galvanized steel tubing |

| Upright Material | 13mm to 20mm diameter, 18-gauge steel tubing |

| Upright Spacing | Typically 110mm, 127mm, or 200mm |

| Feet Types | Flat feet or bridge feet, both removable |

| Connection System | Hook and loop interlocking system |

| Finish | Hot-dip galvanized to prevent corrosion |

| Base Options | Flat feet for pedestrian areas; bridge feet for uneven ground |

| Color Options | Standard galvanized; optional black, orange, or other coatings |

| Usage Applications | Events, construction sites, public gatherings, roadwork |

| Storage and Transport | Stackable in bundles of 25 for easy handling |

| Environmental Benefit | 100% recyclable material |

Differences Between Pre-Galvanized and Hot-Dipped Galvanized Crowd Control Barriers

Both pre-galvanized and hot-dipped galvanized (HDG) crowd control barriers offer corrosion protection, but they differ in coating process, durability, and use cases.

1. Coating Process

- Pre-Galvanized Steel:

- The steel is galvanized before the barrier is fabricated.

- A zinc layer is applied to large sheets or coils of steel through a continuous galvanizing process.

- After fabrication, the cut edges remain exposed, which can reduce corrosion protection over time.

- Hot-Dipped Galvanized (HDG):

- The entire fabricated barrier is dipped into a bath of molten zinc (at around 450°C).

- This process ensures a thicker, uniform zinc coating, covering all edges and welds, leaving no steel exposed to corrosion.

2. Coating Thickness and Durability

- Pre-Galvanized Barriers:

- Zinc coating is usually 10-20 microns thick.

- Offers moderate corrosion resistance, suitable for environments with light exposure to moisture.

- The barrier’s protection may degrade faster over time, especially at exposed edges and welds.

- Hot-Dipped Galvanized Barriers:

- Coating thickness is generally 42-85 microns.

- Provides superior corrosion resistance, even in harsh environments such as coastal areas or heavy industrial zones.

- Ensures longer service life, as the entire barrier (including joints and welds) receives zinc coating.

Stuructures of Crowd Control Barriers

3. Appearance and Finish

- Pre-Galvanized:

- Smoother surface and a more consistent silver color.

- Ideal for projects where aesthetics matter and exposure to moisture is limited.

- Hot-Dipped Galvanized:

- May have a rougher surface with a spangled, uneven finish.

- Suitable for industrial and heavy-duty applications where durability matters more than appearance.

4. Cost and Applications

- Pre-Galvanized Barriers:

- Lower cost compared to HDG due to reduced processing.

- Used for temporary installations, moderate climates, and less harsh environments like indoor events.

- Hot-Dipped Galvanized Barriers:

- Higher initial cost due to the intensive process.

- Ideal for long-term outdoor installations or environments with high exposure to moisture or chemicals, such as coastal areas or construction sites.

Summary Comparison

| Feature | Pre-Galvanized | Hot-Dipped Galvanized (HDG) |

|---|---|---|

| Coating Thickness | 10-20 microns | 42-85 microns |

| Protection at Welds | Limited | Fully coated |

| Corrosion Resistance | Moderate | High |

| Appearance | Smooth, uniform | Rough, spangled |

| Cost | Lower | Higher |

| Ideal Use | Indoor or light-duty outdoor events | Heavy-duty outdoor use, harsh environments |

Optional of feet types

Conclusion

The choice between pre-galvanized and hot-dipped galvanized barriers depends on the intended application and environmental conditions. Pre-galvanized barriers are suitable for short-term or moderate environments, while hot-dipped galvanized barriers are better for long-term outdoor applications where corrosion resistance is essential

Crowd Control Barriers