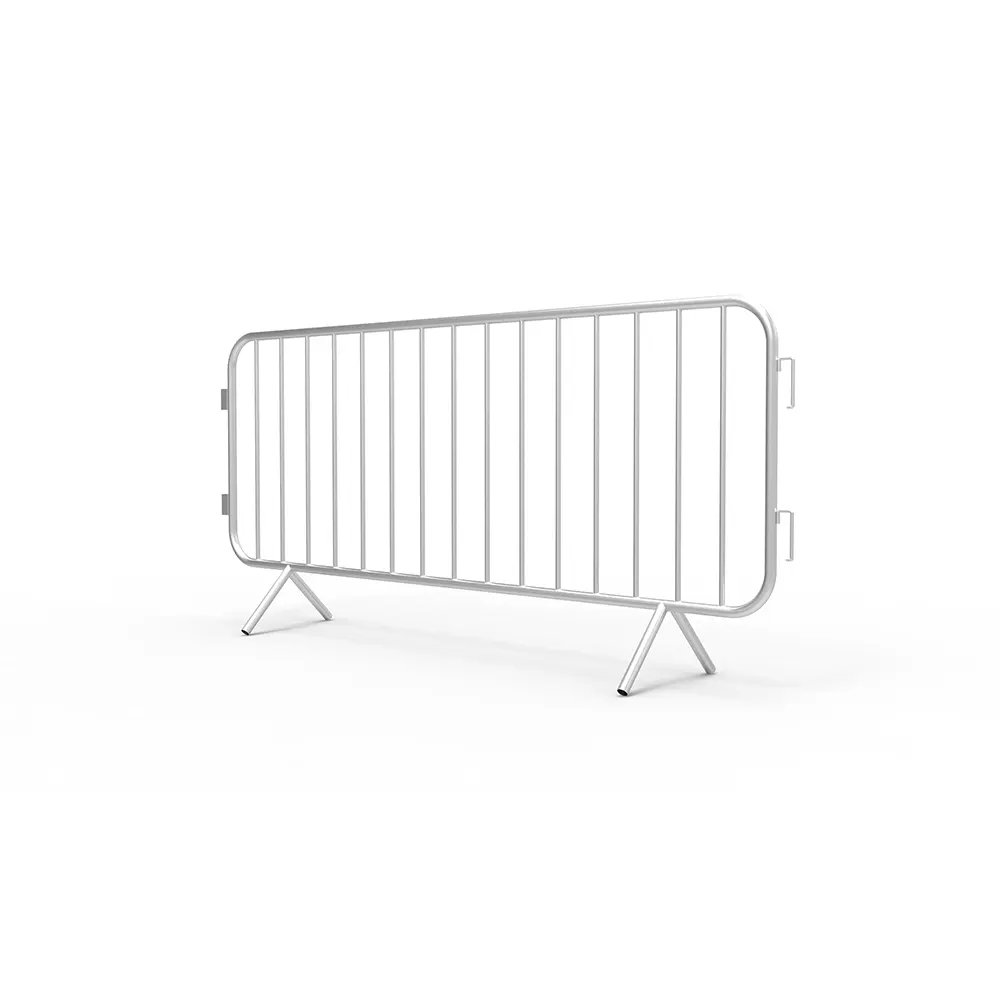

Fixed-leg crowd control barriers

- Purpose: Define restricted areas and guide crowds at outdoor events (concerts, festivals, ag shows, parking lots, construction sites, venues)

- Terrain handling: Fixed legs work on uneven ground without extra accessories

- Sustainability: 100% recyclable steel

- Typical handling weight: ~11.34 kg per barrier (≈25 lb) — up to four can be carried at once

- Persons to lift: 2 people (no special tools required)

- Frame tube OD: 38.1 mm (1.5″)

- Infill rod OD: 16.51 mm (0.65″)

- Infill spacing (gap): ≈111.8 mm (4.4″)

- Uprights per panel: 18–25 (depends on panel length)

- Interlocking: Hook-and-eye connectors for end-to-end runs

- Construction: One-piece tubular frame; horizontal + vertical bars welded; legs permanently welded to main frame

- Description

Fixed-leg crowd control barriers are rugged, all-steel panels with feet permanently welded to the frame for greater stability than detachable-base styles. They’re ideal for defining restricted zones and guiding foot traffic at concerts, festivals, ag shows, stadiums, construction sites, and car parks.

Why Fixed Legs

- Stays put on uneven ground: Offset fixed feet add stability and make placement easy—no extra accessories needed.

- Stronger by design: One-piece tubular frame with fully welded legs minimizes weak points.

- Fast handling: Lightweight enough to carry up to four at once; typically only two people needed to lift a panel.

- Sustainable: Built from 100% recyclable steel.

Design & Materials Fixed-leg crowd control barriers

- Frame: Steel tube, main rail 1.5″ diameter (model-dependent).

- Infill: Central rods 0.65″ tube, 4.4″ spacing for effective crowd containment.

- Uprights: 18–25 per panel (varies by length) for stiffness and durability.

- Interlock: Hook-and-eye connectors join panels end-to-end for a continuous run.

- Finish: Galvanized steel for long-term rust resistance; models offered with zinc electroplate or hot-dip galvanizing (HDG). Optional powder topcoat available on request.

|

|

|

Key Features

- Offset fixed legs for stability and easy stacking/placement

- Hook-and-eye quick-connect system

- Top of frame punched; infill bars slotted into the frame and welded

- Thicker-gauge frame and legs for longer service life

- Entirely welded construction reduces maintenance

Specifications

| Model | Length (mm) | Height (mm) | Tube Ø (mm) | Wall (mm) | Weight (kg) | Per Pallet | Material | Coating Finish |

|---|---|---|---|---|---|---|---|---|

| FDCI114001 | 2286 | 1100 | 38.1 | 0.889 | 10.66 | 18 | Pre-galvanized carbon steel | Zinc electroplated |

| FDCI114002 | 2286 | 1100 | 38.1 | 0.889 | 9.30 | 20 | Pre-galvanized carbon steel | Zinc electroplated |

| FDCI114003 | 1981 or 2438 | 965 or 1118 | 31.75 | 1.651 | 23.13 or 25.40 | 25 | Galvanized carbon steel | Hot-dip galvanized |

*Weight varies slightly by batch and hardware configuration.

Typical handling weight: ~25 lb per barrier (model-dependent).

Applications

-

Events: Concerts, festivals, marathons, parades

-

Venues & parking: Stadium perimeters, car parks, ticketing lines

-

Civic & ag shows: Agricultural field days, fairs, markets

-

Work zones: Construction sites, queuing lanes, exclusion zones

Manufacturing Process Fixed-leg crowd control barriers

-

Material selection & inspection — verify tube thickness, diameter, and zinc uniformity.

-

Cutting — precision cut to length per drawings.

-

Punching — pre-punch holes for connectors and assembly operations.

-

Tube bending — form corners and legs to spec without cracking.

-

Welding — assemble pre-galvanized tubes into a rigid, one-piece frame; weld infill bars.

-

Surface prep — sandblast to remove scale/oil; phosphating to promote coating adhesion.

-

Finishing — zinc electroplate or hot-dip galvanize; optional powder coating if specified.

-

Quality control — check weld integrity, wall thickness, coating thickness, and fit.

-

Packaging — pro crating for safe transport and easy unloading.

FAQs Fixed-leg crowd control barriers

-

Outdoor-ready? Yes—galvanized finishes resist rain and weather.

-

Load rating? Designed to handle heavy crowd environments (up to 2,000 lb static load capacity as specified).

-

Branding? Logo/colour customization available (powder coat or decals).

-

Lead time? Depends on quantity and finish; contact for a schedule.

-

How to order? Share quantities, model(s), and any coatings/branding; we’ll quote and guide you through the process.

Crowd Control Barriers