Edge Protection Barrier : Secure Construction Working Platforms

- Name: Edge Protection Fence

- Wire Diameter: 54mm, 65mm, 8*6mm

- Mesh Size: 75x75mm, 50x100mm, 50x200mm

- Length: 1.5m, 2.0m, 2.5m, 3.0m

- Height: 1.3m, 1.4m, 1.5m, 1.6m

- Bending Degree: 60°, 90°, 12°

- Round Post: 48x2mm, 60x2mm

- Square Post: 50x502mm, 60x602mm

- Color: Yellow, Blue, Red

- Transport Package: Steel Pallet

- Specification: Wire Diameter 5mm/4mm, mesh size 75x75mm, length 1.5m

- Trademark: BMP

- Origin: Anping, Hengshui, China

- HS Code: 7308900000

- Production Capacity: 5000 rolls/month

- Description

Edge Protection Barrier Fences use welded wire mesh panels and provide security for construction working platforms in various applications. These include railway infrastructure, roof edge protection barriers, mesh guard edge protection panels, pontoon mesh edge protection systems for floating platforms, and more. These barriers are customizable and can include toeboards for added safety in construction settings.

|

|

|

|

Early Developments in Edge Protection

The use of edge protection barriers, often referred to as guardrails or safety barriers, dates back to ancient times. The primary purpose was to prevent falls in construction sites, especially in monumental projects like pyramids and other ancient structures. These early barriers were rudimentary, often made from basic materials available at the time.

Industrialization and Early Safety Measures

The early 20th century marked a significant shift with the advent of industrialization and urban development. The increasing complexity and height of construction projects necessitated more formal safety measures. During this period, basic wooden railings and barriers began to be employed to safeguard workers from falls. As awareness of workplace safety grew, so did the sophistication of edge protection solutions.

Advancements in Materials and Design

By the mid-20th century, advancements in materials science led to the adoption of metal barriers, particularly steel, offering superior strength and durability compared to their wooden predecessors. These early metal barriers were manually installed and provided a rudimentary level of protection on construction sites. The post-World War II construction boom saw a heightened focus on safety standards and regulations, prompting the broader use of metal barriers to enhance worker safety.

Specifications Edge Protection Barrier

- Wire Diameter: 5-8mm

- Opening Size: 50x200mm

- Panel Size: 1100x1700mm, 1100x2400mm, 1300x1300mm, 1300x2200mm

- Post Diameter/Thickness: 48mm with 1.5mm or 2.0mm thickness

- Surface Treatment: Options include galvanized with powder coating, galvanized with paint, or black with powder coating

- Customization: Specifications can be tailored to meet specific requirements

Product Description and Benefits Edge Protection Barrier

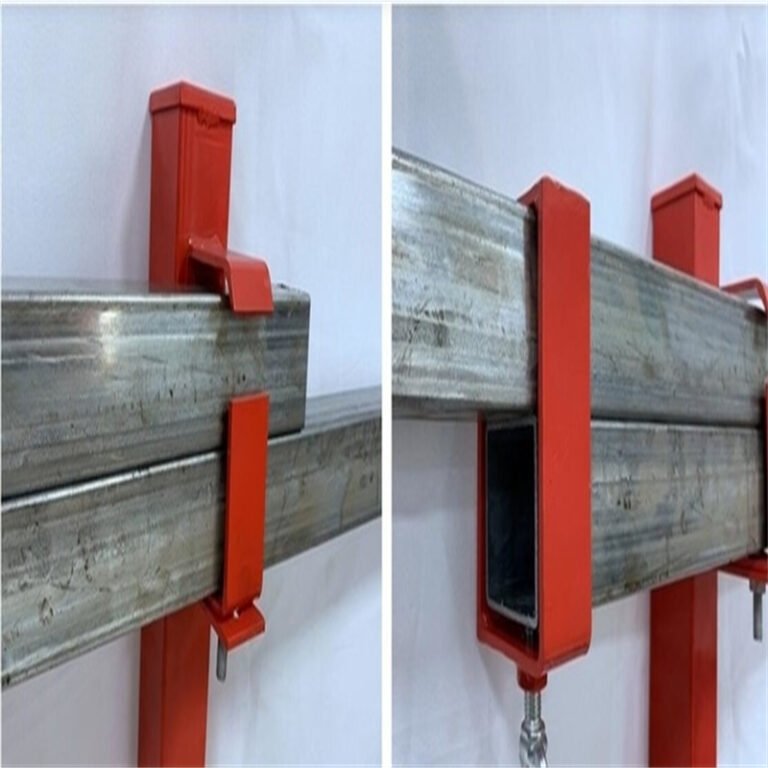

1. High-Quality Raw Materials: Made from low-carbon steel wire, the panels are welded with heavy wire and feature a 90-degree bend at the top and bottom. A toe board is welded at the bottom to prevent small stones from falling, thereby protecting people below. The continuous wire design ensures a smooth, flat, and straight finish without cut wires.

2. Enhanced Safety Features: The 90-degree bending at the top provides a flat and strong surface, enhancing the fence’s shock resistance and ensuring the safety of personnel. The powder-coated surface treatment not only adds to the aesthetic appeal but also provides rust resistance, extending the product’s lifespan and reducing maintenance costs.

3. Reusability and Durability: These fences are designed for multiple uses, making them a cost-effective solution. The toe board at the bottom helps prevent debris from falling, adding an extra layer of safety.

Detailed Specifications Edge Protection Barrier :

| Type | Weight | Length | Height | Finish | Material | Wire Diameter | Mesh Size | Color |

|---|---|---|---|---|---|---|---|---|

| Type 1 | 9 Kg | 1325 mm | 1150 mm | Galv. wire + Powder coat | Metal | 4.0 mm | 50x100mm, 50x200mm | Red, yellow, blue, white (customizable) |

| Type 2 | 16 Kg | 2285 mm | 1150 mm | Galv. wire + Powder coat | Metal | 4.0 mm | 50x100mm, 50x200mm | Red, yellow, blue, white (customizable) |

| Type 3 | 18 Kg | 2585 mm | 1150 mm | Galv. wire + Powder coat | Metal | 4.0 mm | 50x100mm, 50x200mm | Red, yellow, blue, white (customizable) |

|

|

|

|

Introduction to SafeEdge Edge Protection System

SafeEdge provides a simple-to-install edge protection system, essential for ensuring safe work conditions at height. The system includes a range of barrier sizes and heights, with various fixing options tailored to different site requirements.

Dimensions and Setup

SafeEdge barriers come in two standard lengths—1300mm and 2600mm—with post centers typically spaced 2400mm apart. The standard height is 1150mm, with an extra height option for longer barriers. These barriers are designed to be installed around the perimeter of a building shell, either attached to scaffolding, steel work, or directly to concrete slabs.

Primary Function: Worker Safety

The primary purpose of the SafeEdge barriers is to create a temporary safety perimeter around work areas, preventing accidental falls. This is particularly crucial for high-rise construction projects without external walls, where the barriers act as edge protection.

Secondary Function: Debris Containment

SafeEdge barriers also prevent materials and debris from leaving the worksite. The mesh design stops large items from falling, while a kickplate at the bottom of the barrier ensures that smaller debris does not escape underneath, safeguarding both workers and the public below.

System and Installation

This Edge Protection Barrier system offers significant benefits in preventing falls on construction sites due to its ease of use, enhanced safety features, and compliance with EN 13374 standards. It provides maximum protection around construction perimeters, stairwells, lift wells, and excavations. The mesh barriers are straightforward to install, requiring no specialized skills, while also giving a professional appearance to construction sites. A wide range of attachments and accessories makes this system adaptable to almost any construction project.

Construction and Industrial Applications

Edge protection barriers play a vital role in safety across multiple sectors, especially in construction, industrial, and infrastructure projects. On construction sites, these barriers secure the edges of elevated work platforms, preventing falls and ensuring a safe environment. They commonly protect maintenance and construction zones in railway infrastructure, keeping unauthorized individuals out and safeguarding workers.. In addition, these barriers provide crucial roof edge protection, preventing falls during installation, repair, and maintenance. Industrial sites use these barriers to define safe zones around heavy machinery and elevated walkways, reducing accident risks. They are also essential at public events and temporary structures, such as stages and grandstands, where they help secure the perimeter and protect both workers and the public.

Specialized and Additional Uses

Edge protection barriers have specialized uses in marine and waterfront construction, where they prevent falls into the water from pontoons and floating platforms, safeguarding workers and equipment. At excavation sites, these barriers prevent falls into trenches and manage movement around hazardous areas. When used with scaffolding, they provide additional safety by securing the edges of working platforms. In commercial and residential complexes, edge protection barriers protect workers and equipment during construction and maintenance, clearly marking work areas. In demolition sites, these barriers contain debris and ensure safety by securing the perimeter of the demolition area.

Packaging & Shipping

The product comes packaged with care to ensure safe transportation, using wooden pallets and plastic packaging tailored to customer needs. This careful packaging helps maintain the quality and integrity of the fence panels during shipping.

This Edge Protection Barrier Fence offers a durable and flexible solution for various construction safety needs, providing easy installation and a professional finish.

|

|

|

|

Edge Protection Fence