Categories

- Recent Updates

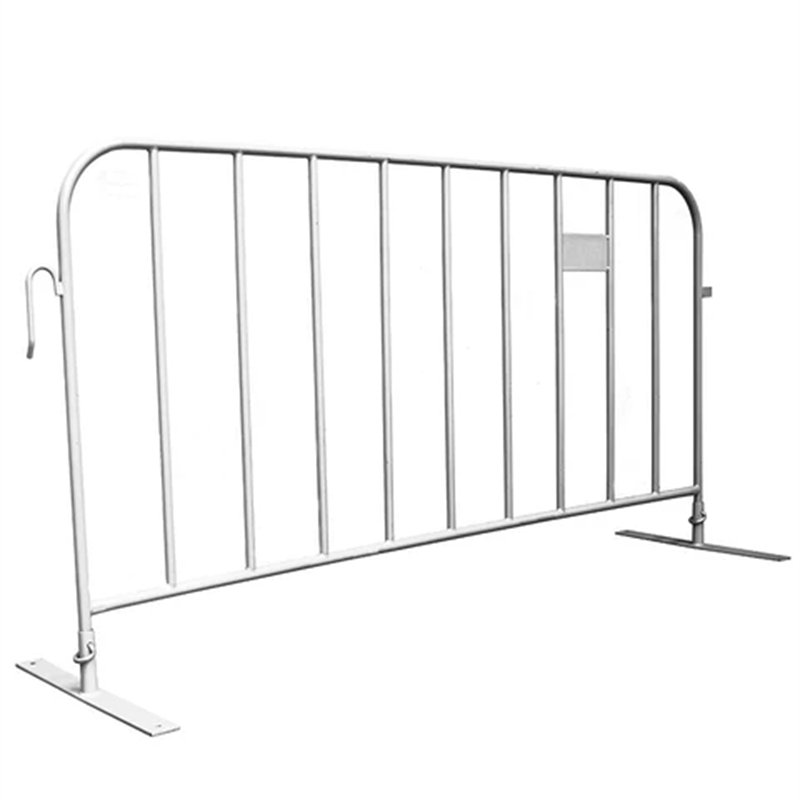

Crowd control barriers are essential tools used to manage and direct the movement of people in various settings, ensuring safety, security, and order. They are widely employed in events, public spaces, construction sites, and any environment where controlling pedestrian flow is crucial. This article provides a comprehensive overview of crowd control barriers, their types, applications, and the considerations for selecting the appropriate barrier for specific needs.

|

|

|

|

Constructed from durable materials like steel, these robust barriers are ideal for large-scale events, concerts, and festivals. They provide a high level of security and effectively prevent unauthorized access.

These specifications offer a range of options to suit different needs. The heavy-duty barriers provide extra durability with thicker tubes and more weight. The light-duty barriers are lighter and may be easier to handle. All barriers come with treatment options to enhance corrosion resistance and appearance.

| Specification | 25mm Series Heavy Duty | 25mm Series Light Duty | 32mm Series Heavy Duty | 32mm Series Light Duty |

|---|---|---|---|---|

| Height | 1100mm | 1100mm | 2100mm | 2100mm |

| Width | 2100mm | 2100mm | 1100mm | 1100mm |

| Tube Diameter (OD) | 25mm x 2.00mm | 25mm x 1.50mm | 32mm x 2.00mm | 32mm x 1.50mm |

| Upright Diameter (OD) | 20mm x 1.50mm | 20mm x 1.20mm | 14mm x 1.50mm | 14mm x 1.20mm |

| Number of Upright Tubes | 9 pcs | 9 pcs | 17 pcs | 17 pcs |

| Base | Flat Steel Base 500mm x 50mm x 10mm | Flat Steel Base 500mm x 50mm x 10mm | Flat Steel Base 500mm x 50mm x 10mm | Flat Steel Base 500mm x 50mm x 10mm |

| Weight | 18kg | 15kg | 22kg | 18kg |

| Spacing Between Tubes | 185mm | 185mm | 100mm | 100mm |

| Treatment Available | Hot Dipped Galvanized, Pre-galvanized, Polyester Powder Coated | Hot Dipped Galvanized, Pre-galvanized, Polyester Powder Coated | Hot Dipped Galvanized, Pre-galvanized, Polyester Powder Coated | Hot Dipped Galvanized, Pre-galvanized, Polyester Powder Coated |

| Kit Components | 1 Panel + 2 Flat Feet | 1 Panel + 2 Flat Feet | 1 Panel + 2 Flat Feet | 1 Panel + 2 Flat Feet |

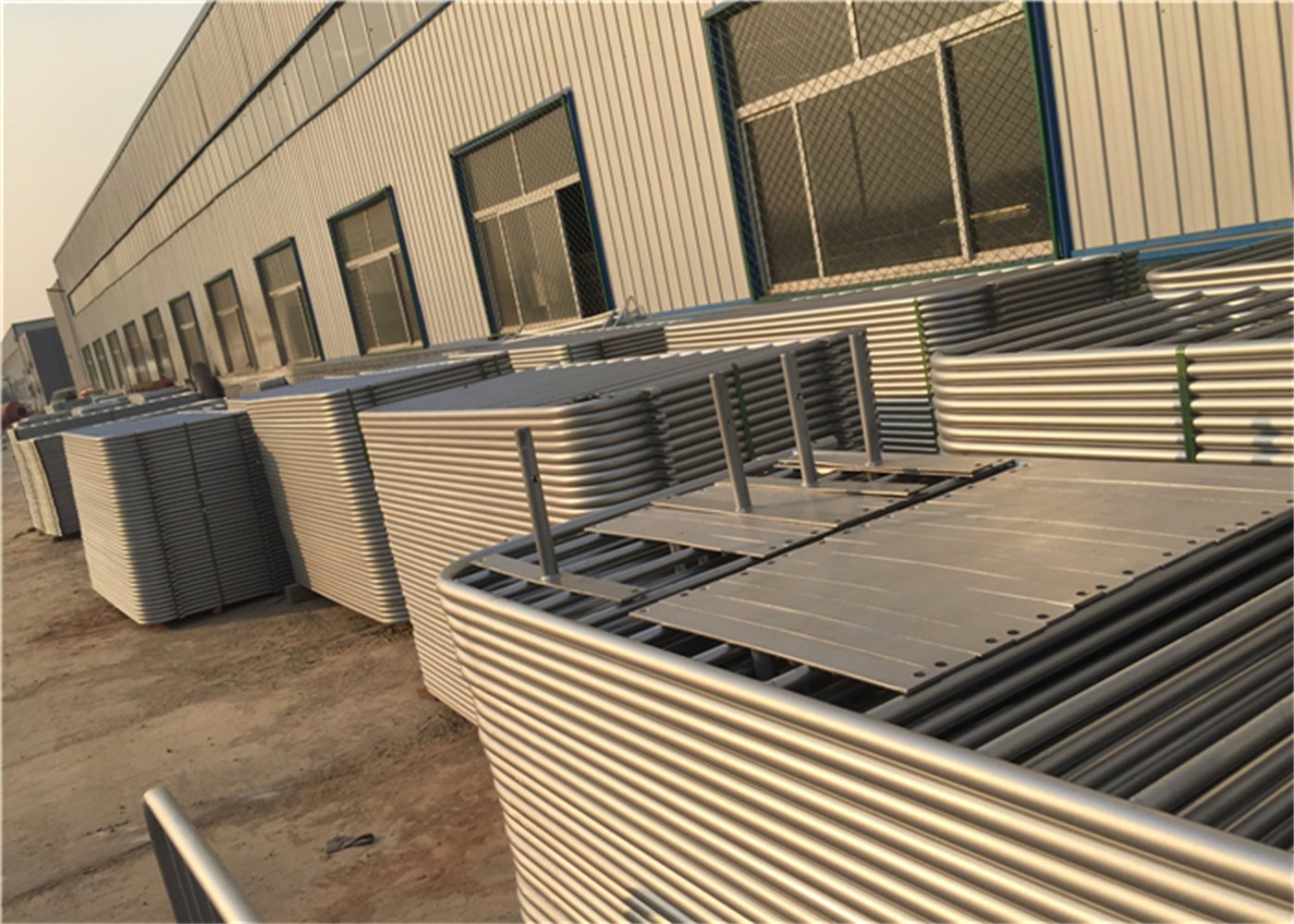

Galvanized Crowd Control Barriers Available pre-galvanized and hot dipped galvanized |

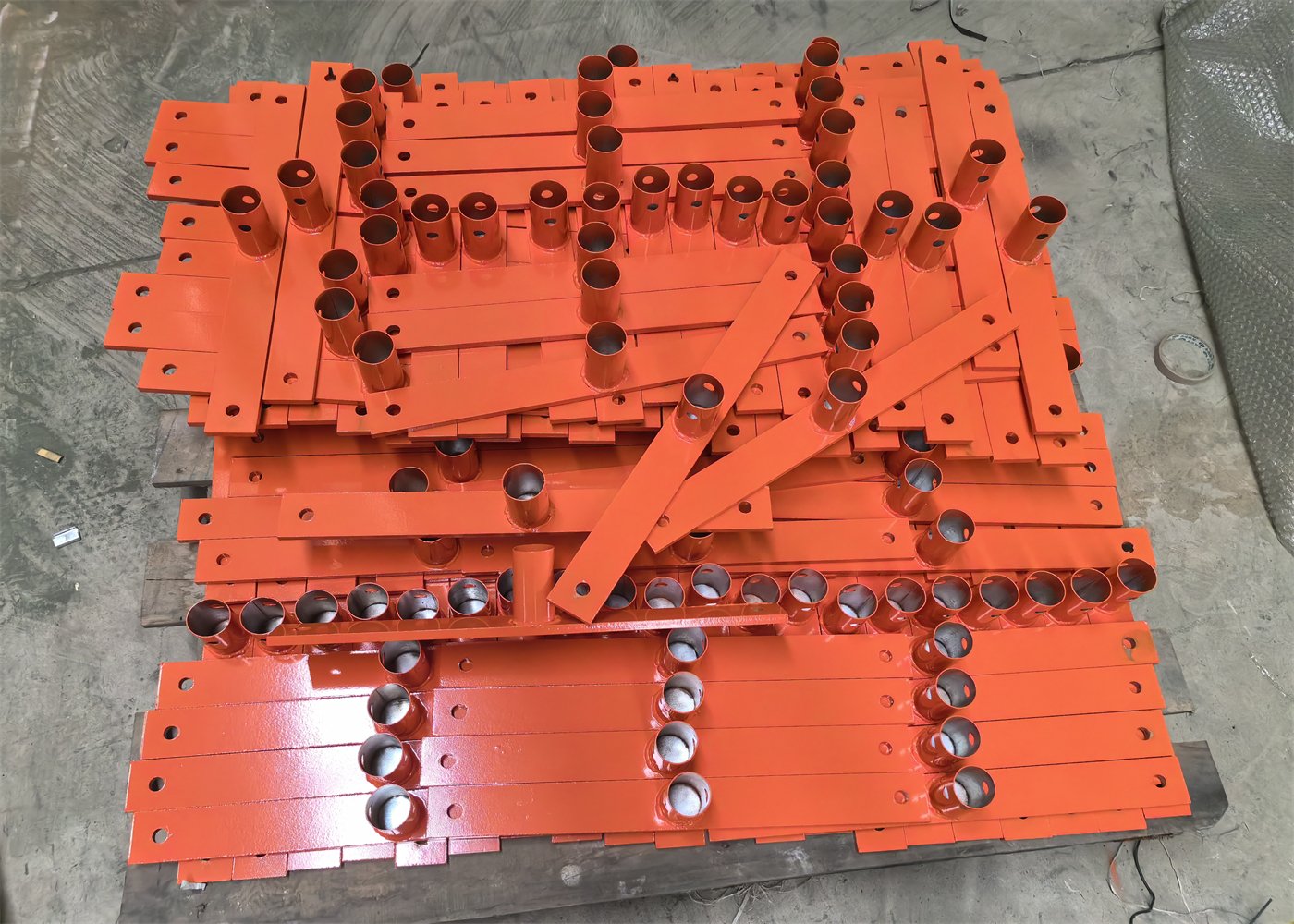

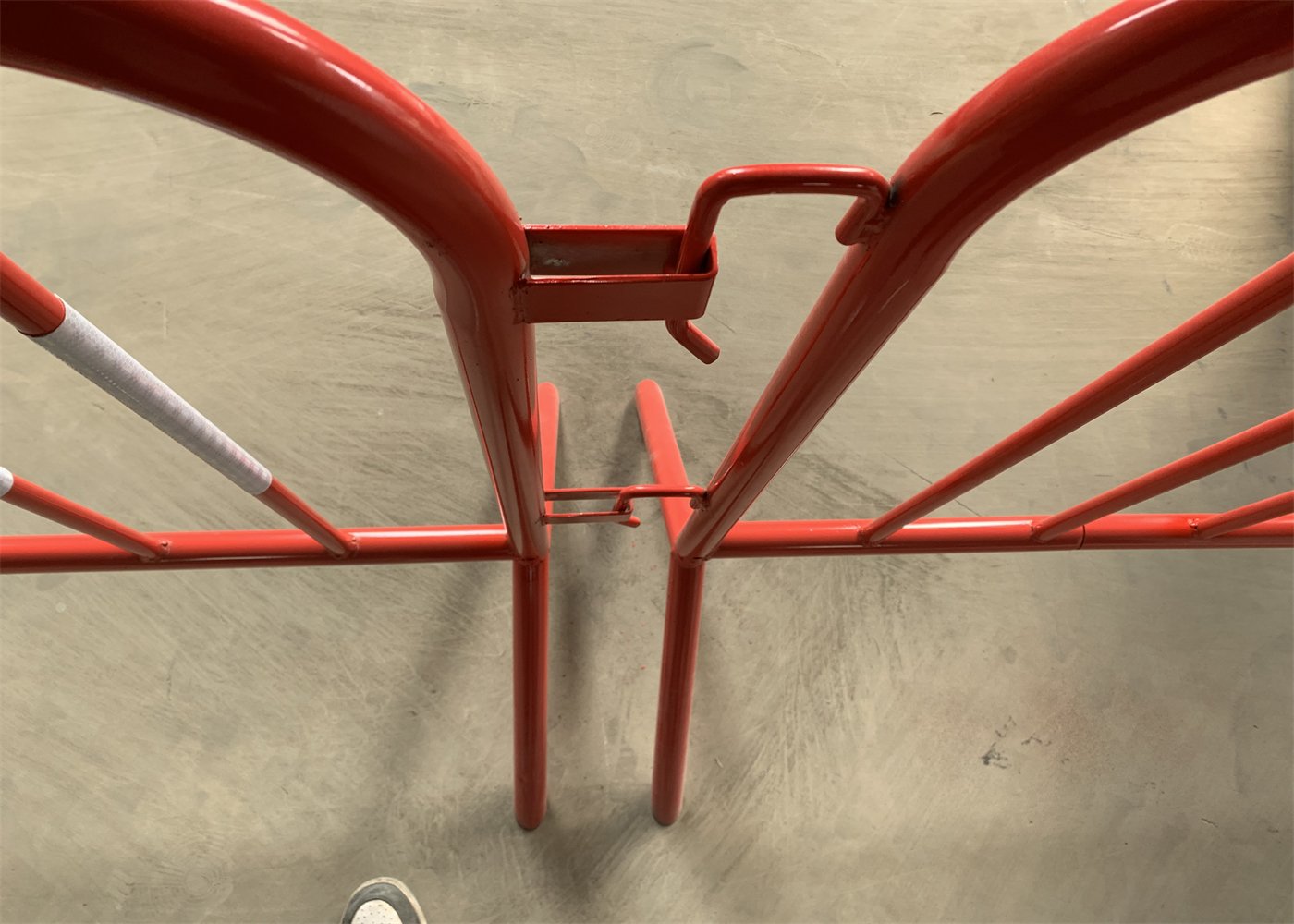

Orange powder coated Crowd Control Barriers |

Bottom foot designs |

Gate design |

Tube thickness greatly affects the price of metal crowd control barriers. Thicker tubes use more steel, which increases material costs. Therefore, barriers with thicker tubes are more expensive.

Freight cost also influences the price. Shipping heavy metal barriers can be costly, especially over long distances. If freight costs rise, the overall price of the barriers goes up.

Steel price is another key factor. When the market price of steel increases, production costs for the barriers rise. This leads to higher prices for the finished product.

The currency exchange rate between USD and Australian dollars impacts the price as well. If the USD strengthens against the Australian dollar, importing barriers becomes more expensive for Australian buyers. Conversely, if the Australian dollar strengthens, the barriers become cheaper.

In summary, tube thickness, freight cost, steel price, and currency exchange rates all play significant roles in determining the price of metal crowd control barriers.

Purchasing crowd control barriers in small quantities from local suppliers in Australia costs between $48 and $110, including GST. But if you buy imported crowd control barriers from China, the price is much lower. When landed at main Australian ports like Brisbane, Sydney, and Melbourne, the cost ranges from around $25 to $55 per kit.If you are seeking crowd control barriers for hire and are interested in obtaining a quote, we have prepared contact information for 18 reputable suppliers for your reference.

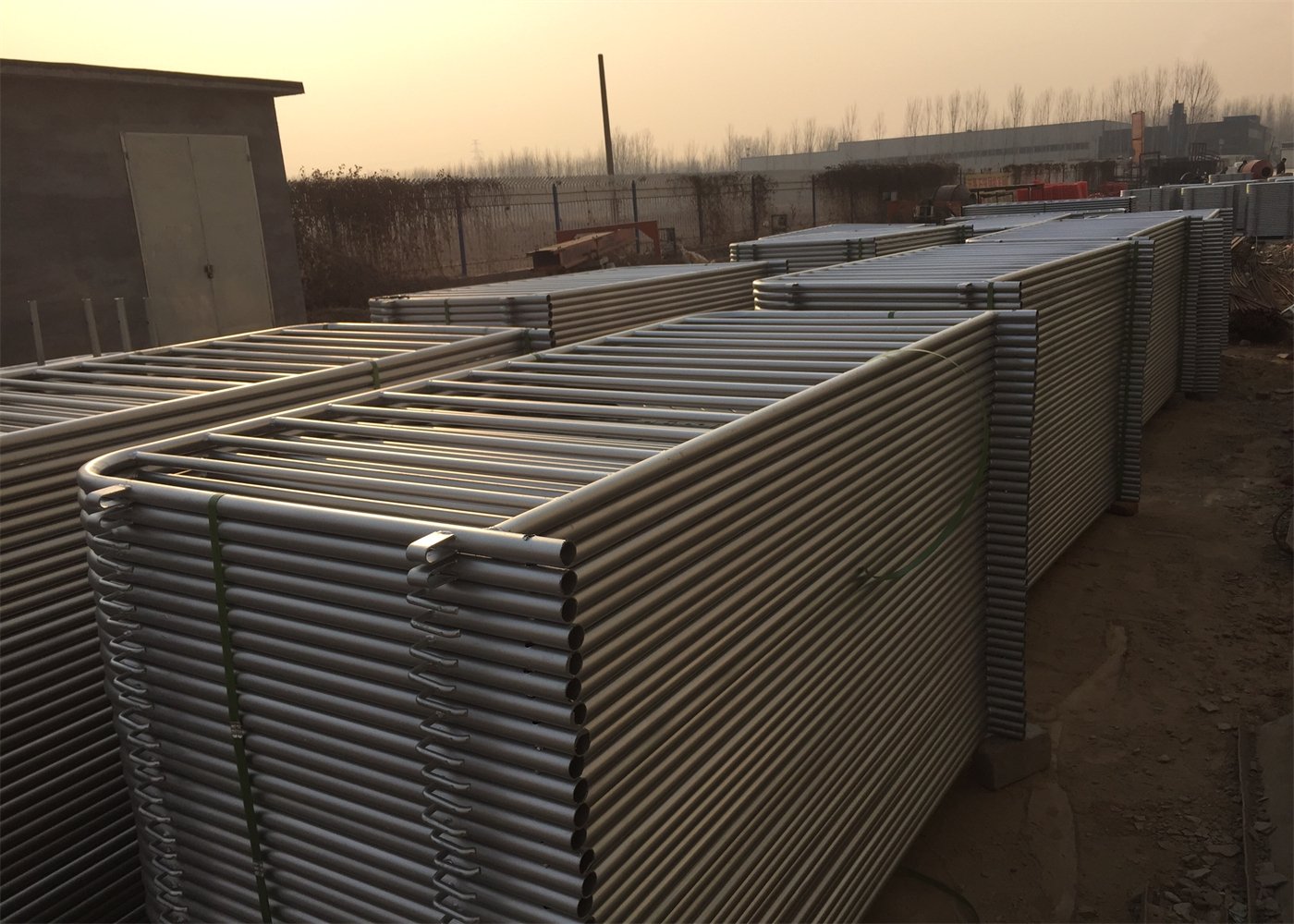

The standard method for packing crowd control barriers involves placing the panels onto metal pallets. To maintain the balance of the entire pallet, it’s important not to have all the round top sides facing the same direction. The correct packing procedure is to alternate the orientation: one piece with the round top facing one way, then the next piece facing the opposite direction.

The packing methods differ between galvanized crowd control barriers and polyester powder-coated crowd control barriers. The notable difference is that for powder-coated barriers, a layer of plastic film is placed between each barrier to protect the finish. The sequence is: one layer of plastic film, then one barrier, followed by another layer of plastic film.

Typically, OD25mm crowd control barriers are packed with approximately 100 pieces per pallet. 32mm crowd control barriers usually have 75 pieces per pallet, and 38mm crowd control barriers are packed with about 65 pieces per pallet.

Generally, the steel plate feet of the crowd control barriers are placed into the upright spacing between the barriers for efficient use of space. In orders with higher requirements, the feet are often placed in cardboard boxes for additional protection.

stacking in metal pallets |

base plate put in upright tubes |

crowd control barriers container loading |

each barriers stacking with a extra plastic film |

as per requirements the base plate put in paper carton |

metal barriers wrapped with plastic film |

Crowd control barriers are essential for ensuring safety and order in public spaces, construction sites, and event venues. In Australia and New Zealand, these barriers must adhere to specific standards that ensure durability, safety, and compliance with local regulations. The treatments applied to these barriers—such as pre-galvanizing, polyester powder coating, and hot-dip galvanizing—are critical for their performance and longevity.The zinc layer on pre-galvanized crowd control barriers typically breaks after welding. To prevent rust, a cold zinc coating is usually applied as an anti-corrosion treatment.

|

|

|

|

Process Overview: Pre-galvanizing involves coating steel with a thin layer of zinc before fabrication. This is typically done by running steel sheets through a molten zinc bath and then forming them into the desired shape.

Advantages:

Limitations:

Relevant Standards in Australia and New Zealand:

Process Overview: Polyester powder coating involves applying a dry powder to the metal surface electrostatically and then curing it under heat to form a protective layer.

|

|

|

|

Advantages:

Limitations:

Relevant Standards in Australia and New Zealand:

Process Overview: Hot-dip galvanizing involves immersing the fabricated steel barrier into a bath of molten zinc, creating a robust, metallurgically bonded zinc coating.

|

|

|

|

Advantages:

Limitations:

Relevant Standards in Australia and New Zealand:

Beyond the coating treatments, crowd control barriers must comply with several other standards to ensure safety and functionality:

Crowd control barriers are essential tools for managing people and ensuring safety at events, construction sites, and public gatherings. One critical aspect of these barriers is the design of their feet, which affects stability, ease of installation, and safety for pedestrians. This article explores the three main types of crowd control barrier feet—bridge foot, flat-style foot, and V-type foot—and provides guidance on how to choose the right one for your specific needs

1. Bridge Foot

The bridge foot design is one of the most popular options for crowd control barriers. Its unique shape resembles a small bridge, providing exceptional stability and making it ideal for use on uneven or soft surfaces like grass, gravel, or turf.

|

|

|

|

The flat-style foot barrier is designed with a flat base that lies flush with the ground. This design minimizes tripping hazards and allows for easy passage over the feet by pedestrians and vehicles.

|

|

|

|

The V-type foot features a V-shaped support that balances stability with portability. This design allows for quick assembly and disassembly, making it convenient for events that require rapid setup and takedown.

|

|

|

|

Selecting the appropriate barrier foot depends on several factors:

Choosing the right crowd control barriers foot is essential for the safety, efficiency, and success of your event or project. By considering factors such as surface type, crowd density, safety concerns, and logistical needs, you can select the barrier foot design that best suits your requirements. Whether it’s the stability of the bridge foot, the safety of the flat-style foot, or the versatility of the V-type foot, understanding these options ensures effective crowd management and a smoother operational experience.

Lightweight and versatile, plastic barriers are well-suited for smaller events such as conferences and exhibitions. They are easy to assemble, transport, and can be customized with event-specific branding.

|

|

|

|

Specifications

| Model No | Length | Total Height | Barrier Body Height | Base Width | Base Height | Total Weight | Color |

|---|---|---|---|---|---|---|---|

| BMP-PCCB-1 | 2 Meter | 1000mm | 800mm | 440mm | 200mm | 12kg | Orange/Yellow, White/Blue/Green |

| BMP-PCCB-2 | 1.1 Meter | 1000mm | 800mm | 440mm | 200mm | 9kg | Orange/Yellow, White/Blue/Green |

| BMP-PCCB-3 | 1.1 Meter | 1000mm | 800mm | 440mm | 200mm | 20kg | Orange/Yellow, White/Blue/Green |

| BMP-PCCB-4 | 2 Meter | 1000mm | 800mm | 440mm | 200mm | 9kg | Silver |

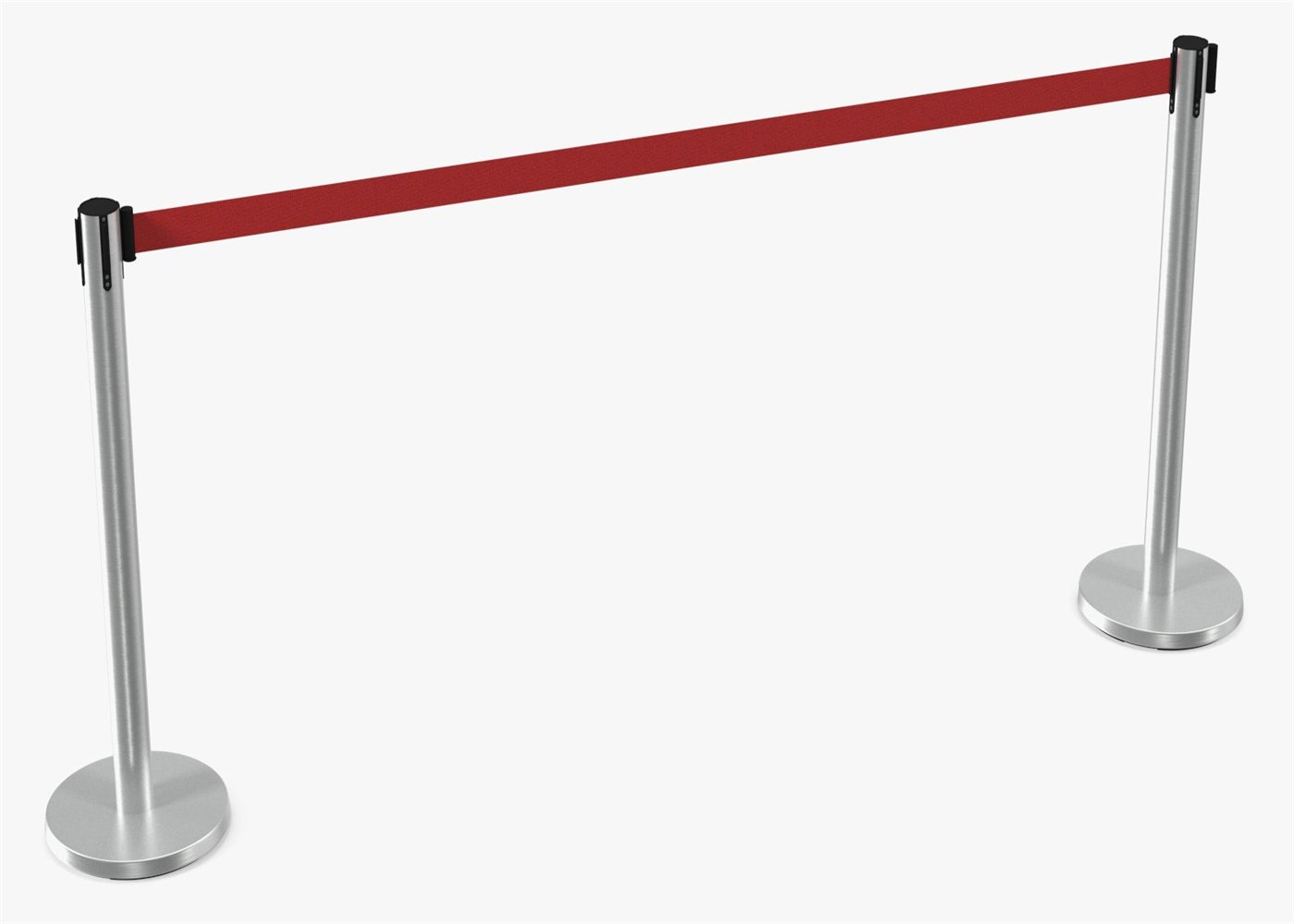

Commonly used in indoor settings like museums, exhibitions, and queues, these portable and visually appealing barriers help maintain orderly and organized lines.

| Specification | Details |

|---|---|

| Item No. | SJ36IK |

| Belt | 2.3–3.6m length / 4.8cm width |

| Tube | Diameter 63.50mm |

| Cover | Diameter 360mm, stackable over |

| Base | Stackable iron base |

| Overall Height | 950mm |

|

|

|

|

|

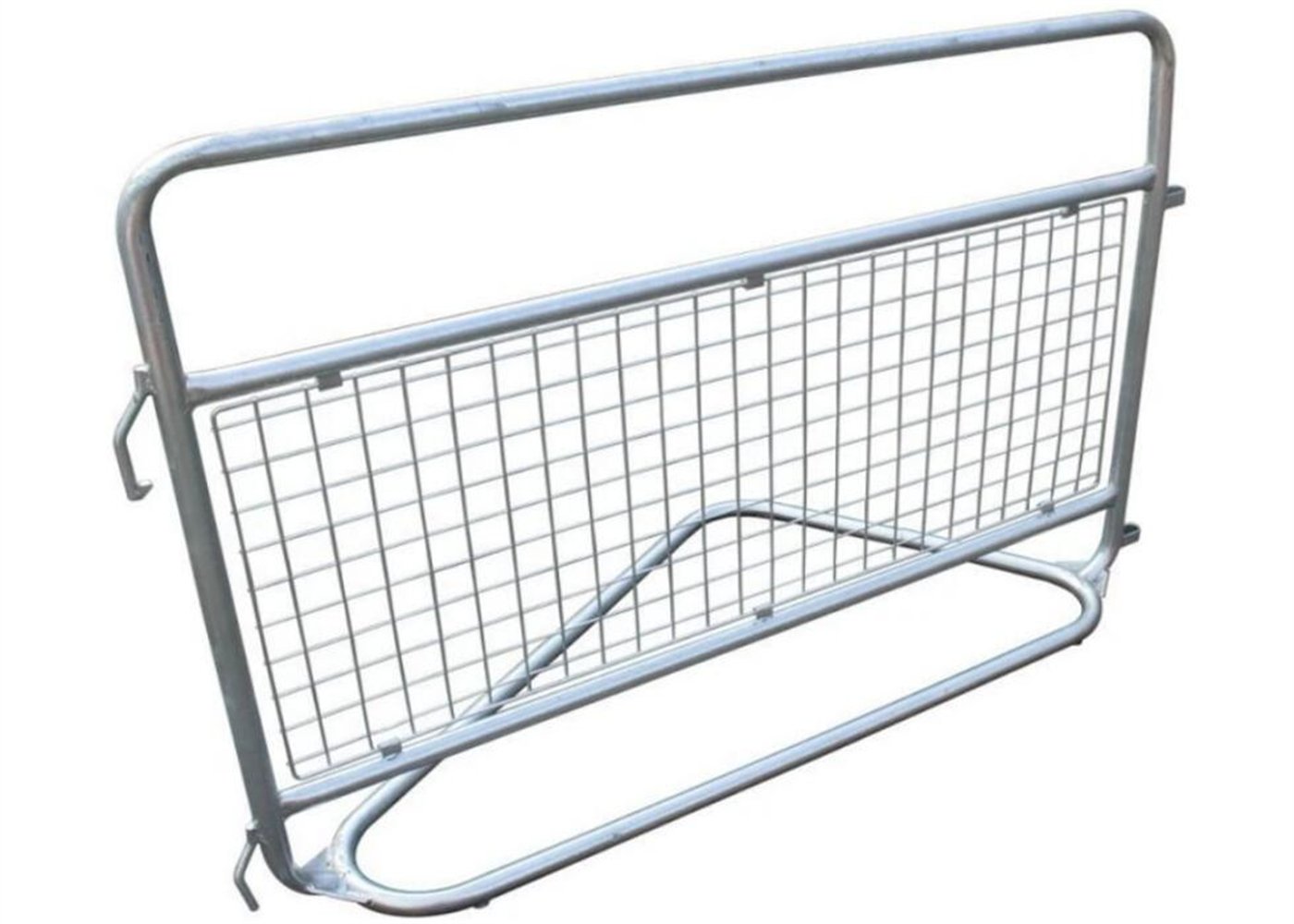

Specifically designed for crowd control and public safety, police barriers are sturdy and reliable solutions for managing large gatherings, parades, and high-security events. Made from heavy-duty materials, they offer enhanced security measures and effectively prevent unauthorized access and disruptions.

|

|

|

|

| Article | Length (mm) | Width (mm) | Height (mm) | Diam. Tube (mm) | Mesh Dimension (mm) | Wire Thickness (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| EMS 1501 | 1526 | 705 | 1065 | 33.7 | 45 x 45 | 2.2 x 3.2 | 26 |

| EMS 1520 | 2000 | 705 | 1100 | 33.7 | 45 x 45 | 2.2 x 3.2 | 35 |

| EMS 1545 | 1675 | 815 | 1255 | 33.7 | 45 x 45 | 2.2 x 3.2 | 40 |

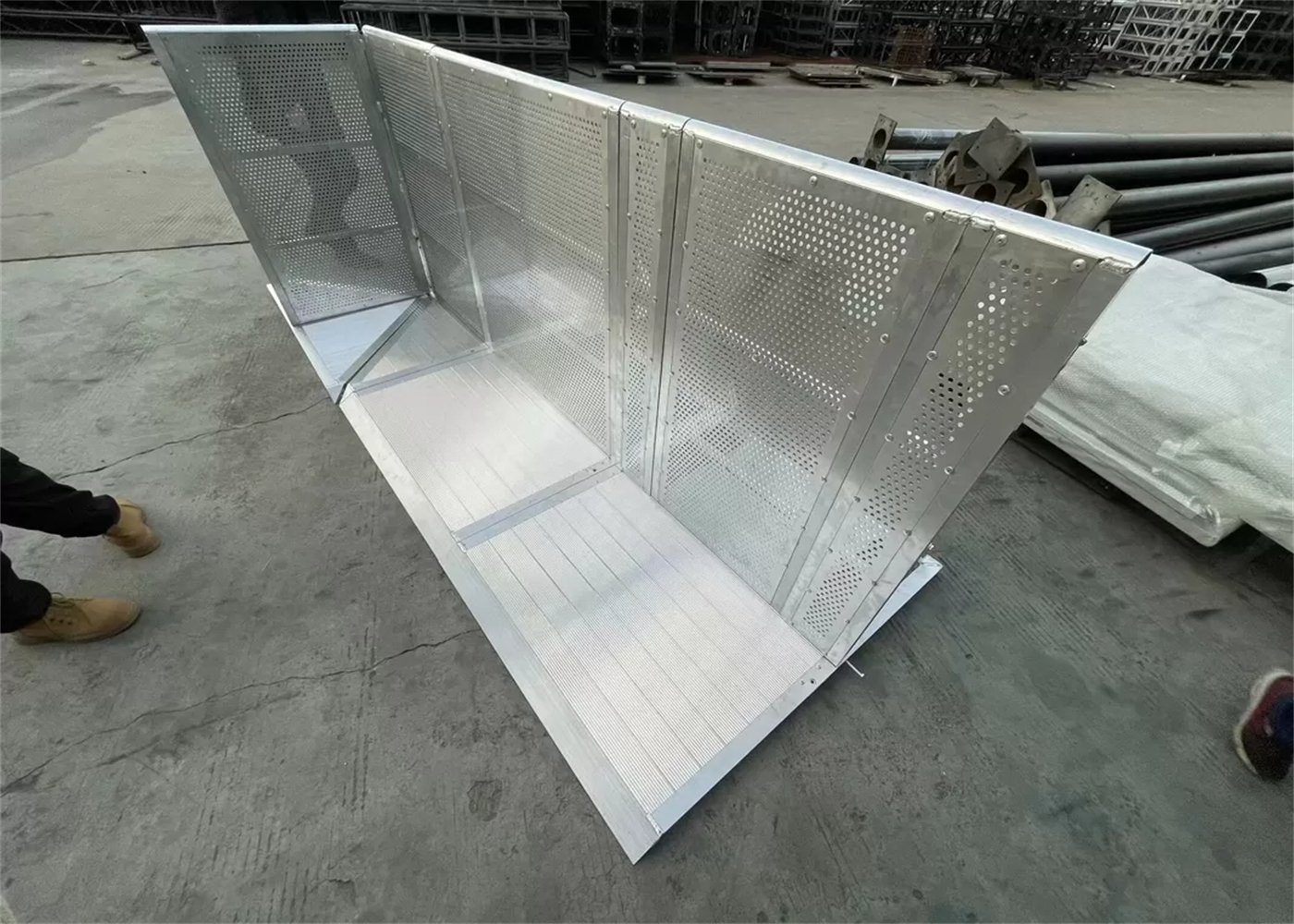

Mojo Barriers is a leading company that specializes in designing and manufacturing high-quality crowd control barriers. Their products are widely used at concerts, festivals, and large events to ensure crowd safety and security. Known for their durability, lightweight construction, and easy installation, Mojo crowd control Barriers offer reliable solutions for managing crowds and creating safe environments for both attendees and performers. The company has a strong reputation for innovation and excellence in the event safety industry.

|

|

|

|

| Specification | Details |

|---|---|

| Material | Aluminium Alloy 6061 T6 |

| Dimension (HxDxW) | 1.2m × 1.2m × 1.0m |

| Semicircle Tube | 50 × 2.0mm |

| Square Tube | 40 × 50 × 2.0mm |

| Perforated Metal THK | 2.0mm |

| Baffle Thickness | 3.0mm |

| Weight | Around 28kg-30kg |

| Unit Package | 1.26m × 1.06m × 0.13m |

Crowd control barriers are indispensable tools for managing pedestrian flow and ensuring safety across various settings, including events, construction sites, and public spaces. They come in multiple forms, each tailored to specific needs and environments.

Metal Crowd Control Barriers are robust and ideal for large-scale events like concerts and festivals. Their specifications vary in height, width, tube diameter, and weight, affecting their durability and price. Key factors influencing their cost include tube thickness, freight expenses, steel prices, and currency exchange rates. Proper packing methods and treatments—such as pre-galvanizing, polyester powder coating, and hot-dip galvanizing—enhance their longevity and compliance with standards like AS/NZS 4792 and AS/NZS 4680 in Australia and New Zealand.

In summary, choosing the appropriate crowd control barrier involves assessing factors such as event scale, environmental conditions, required durability, compliance with safety standards, and budget constraints. By understanding the various types and specifications, one can select barriers that effectively manage crowds, enhance safety, and contribute to the smooth operation of events and public spaces.