Crowd Control Barrier: Specifications, Applications & Packing

Product Name: Crowd Control Barrier

Material: Galvanized tube

Surface Treatment: Hot dipped galvanized

Panel Size: 914x2440mm, 1090x2000mm, 1090*2010mm

Frame: 20mm, 25mm, 32mm, 40mm, 42mm, 48mm OD

Infill Picket: 12mm, 14mm, 16mm, 20mm OD

Spacing: 100mm, 120mm, 190mm, 200mm

Feet: Flat feet, bridge feet, tube feet

Application: Public events, sports, concerts

Assembly: By Interlock Hooking System

Price: 18.22$-49.11$ per kit

HS Code: 73144900

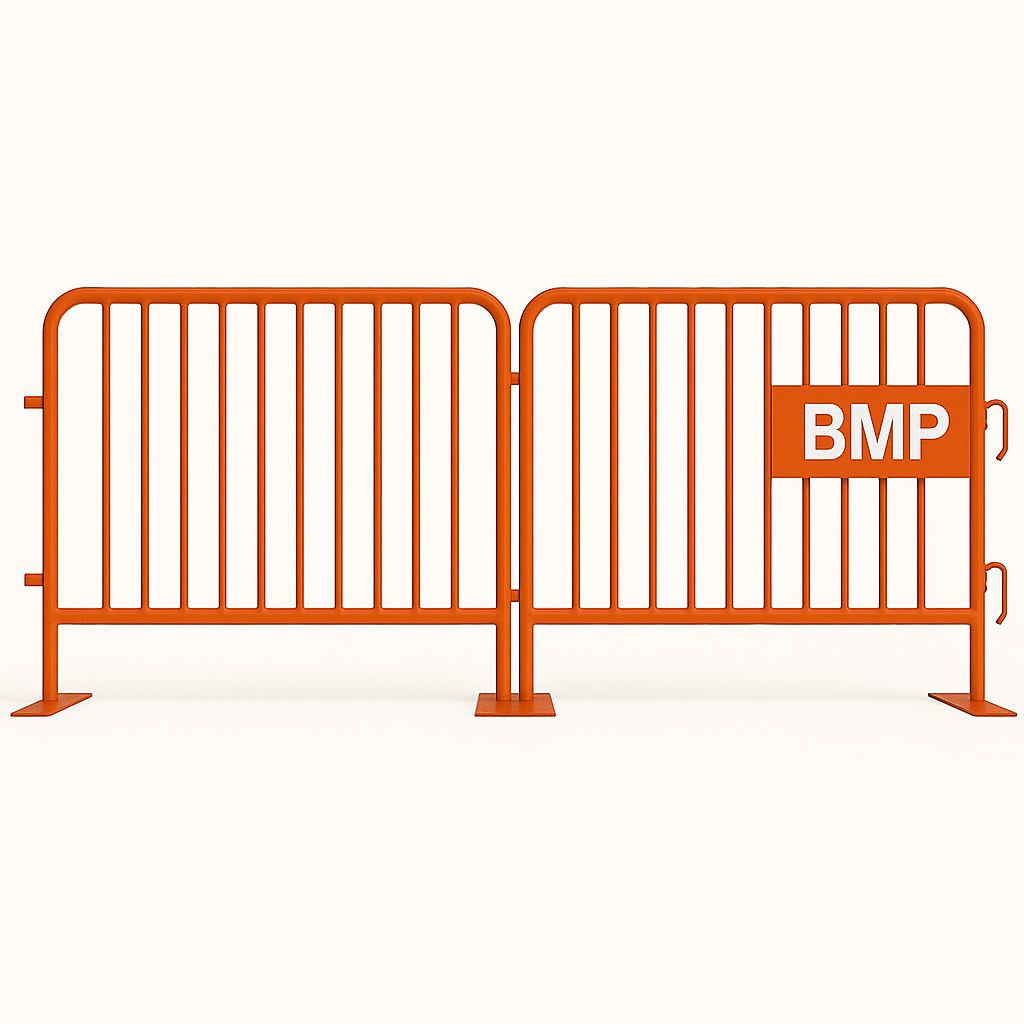

- Description

Crowd control barriers are essential tools for managing large crowds at events, construction sites, and public spaces. They help guide pedestrian traffic, ensure safety, and create designated areas. These barriers are built from durable materials and offer different base and customization options to suit various needs.

We offer a wide range of crowd control barriers in different sizes and designs, built with strong steel frames and infill panels that add extra strength and keep lines straight on site. Whether it’s for temporary events or long-term construction projects, our crowd control barriers provide reliable, repeatable control. The feet options—including flat feet, welded fixed feet, and bridge feet—help maintain stability across asphalt, concrete, and uneven ground. Most buyers reach a point where they also need to decide where to buy crowd control barriers for the right mix of stock availability, compliance, and delivery speed, especially when timelines are tight.

|

|

|

|

|

|

Specifications Crowd Control Barrier

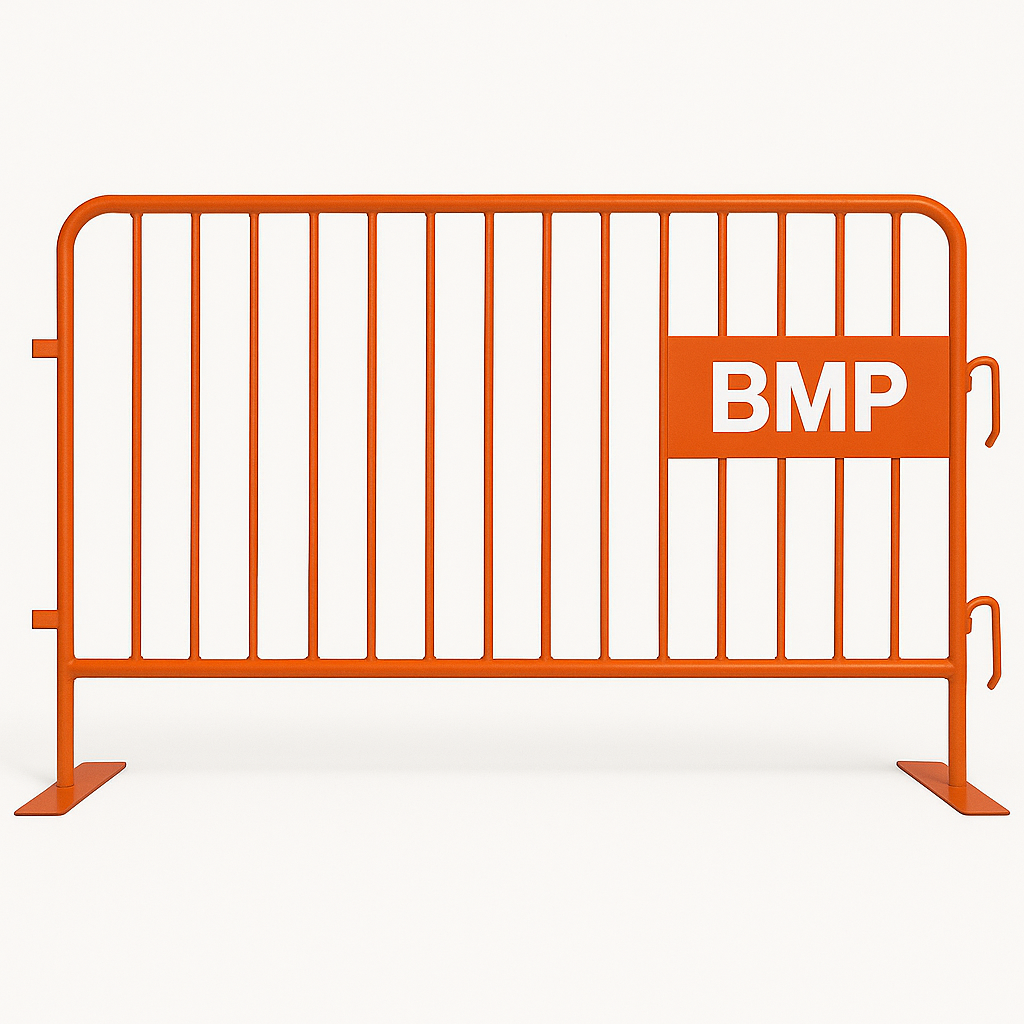

Our crowd control barriers are available in a wide range of sizes, materials—such as Q195 steel, Q235 steel, and Aluminium 6063 T6—and practical designs to match different site conditions and crowd-flow needs, including plastic crowd control barriers for lighter-duty events and safety zoning. Each panel is built on a rigid frame and reinforced with an infill section to improve strength, alignment, and overall control performance.

To suit real-world deployment, we offer multiple base styles including fixed feet, flat feet, and bridge feet, helping the barrier line stay stable on uneven ground and high-traffic surfaces. Detailed specifications are provided for frame OD, infill tube size and thickness, and overall panel dimensions so you can select a compliant option with confidence—whether you’re purchasing for long-term use or planning short-term setups like crowd control barriers hire for events, worksites, or temporary access control.

For finish protection, our barriers can be hot-dip galvanized and pre-galvanized /or powder coated to improve corrosion resistance and extend service life in both indoor and outdoor environments.

General Crowd Control Barrier Specifications

| Frame (OD × T, mm) | Infilled Pipe (OD × T, mm) | Panel Width (m) | Panel Height (m) | Foot | Surface Treatment |

|---|---|---|---|---|---|

| 32 × 1.2 | 12 × 0.7 | 2.0 | 1.1 | Welded on the frame or removable | Hot dipped galvanized |

| 38 × 1.2 | 14 × 1.0 | 2.1 | 1.25 | Welded on the frame or removable | Galvanized + powder coated |

| 42 × 1.2 | 16 × 1.0 | 2.2 | 1.5 | Welded on the frame or removable | Hot dipped galvanized |

| 48 × 1.2 | 20 × 1.2 | 2.4 | 1.5 | Welded on the frame or removable | Galvanized + powder coated |

| 48 × 1.5 | 25 × 1.2 | 2.5 | 1.5 | Welded on the frame or removable | Hot dipped galvanized |

Australian Crowd Control Barriers Specifications

| Specification | 25mm Series Heavy Duty | 25mm Series Light Duty | 32mm Series Heavy Duty | 32mm Series Light Duty |

|---|---|---|---|---|

| Panel Size (H × L, mm) | 1100 × 2100 | 1100 × 2100 | 1100 × 2100 | 1100 × 2100 |

| Frame Tube (OD × T, mm) | 25 × 2.00 | 25 × 1.50 | 32 × 2.00 | 32 × 1.50 |

| Upright Tube (OD × T, mm) | 20 × 1.50 | 20 × 1.20 | 14 × 1.50 | 14 × 1.20 |

| Number of Upright Tubes | 9 pcs | 9 pcs | 17 pcs | 17 pcs |

| Spacing Between Uprights (mm) | 185 | 185 | 100 | 100 |

| Base / Feet | Flat steel base 500 × 50 × 10 mm | Flat steel base 500 × 50 × 10 mm | Flat steel base 500 × 50 × 10 mm | Flat steel base 500 × 50 × 10 mm |

| Weight (kg) | 18 | 15 | 22 | 18 |

| Treatment Available | Hot dipped galvanized / Pre-galvanized / Polyester powder coated | Hot dipped galvanized / Pre-galvanized / Polyester powder coated | Hot dipped galvanized / Pre-galvanized / Polyester powder coated | Hot dipped galvanized / Pre-galvanized / Polyester powder coated |

| Kit Components | 1 panel + 2 flat feet | 1 panel + 2 flat feet | 1 panel + 2 flat feet | 1 panel + 2 flat feet |

American Crowd Control Barriers Specifications

| Panel Length (ft / m) | Panel Height (in / mm) | Frame Tube (OD × T, mm) | Inner Tube (OD × T, mm) | Inner Tube Distance (mm) | Feet Specifications | Surface Treatment |

|---|---|---|---|---|---|---|

| 6.5′ / 1.98 m | 36″ / 914 mm | Φ38 × 1.5 | Φ12 × 1.2 | 110 | Flat: 50×580×6 mm; Bridge: 675×500 mm; V-feet height: 270 mm | Hot-dipped galvanized (after welding) |

| 7.0′ / 2.13 m | 40″ / 1016 mm | Φ38 × 1.8 | Φ12 × 1.5 | 120 | Flat: 50×580×6 mm; Bridge: 675×500 mm; V-feet height: 270 mm | PVC coated after galvanized (after welding) |

| 7.5′ / 2.29 m | 47″ / 1194 mm | Φ38 × 2.0 | Φ16 × 1.5 | 150 | Flat: 50×580×6 mm; Bridge: 675×500 mm; V-feet height: 270 mm | Hot-dipped galvanized (after welding) |

| 8.0′ / 2.44 m | 60″ / 1524 mm | Φ38 × 1.5 | Φ12 × 1.2 | 110 | Flat: 50×580×6 mm; Bridge: 675×500 mm; V-feet height: 270 mm | Hot-dipped galvanized (after welding) |

| 8.5′ / 2.59 m | 60″ / 1524 mm | Φ38 × 2.0 | Φ16 × 1.5 | 150 | Flat: 50×580×6 mm; Bridge: 675×500 mm; V-feet height: 270 mm | PVC coated after galvanized (after welding) |

European Crowd Control Barriers Specifications

| Panel Length (m) | Panel Height (mm) | Frame Tube (OD × T, mm) | Inner Tube / Rod | Inner Tube Distance (mm) | Feet Specifications | Surface Treatment |

|---|---|---|---|---|---|---|

| 2.0 | 900 | Φ38 × 1.5 | Φ16 × 1.2 | 110 | Flat: 50×580×6 mm; Bridge: 675×500 mm; V-feet height: 270 mm | Hot-dipped galvanized (after welding) |

| 2.2 | 1000 | Φ38 × 1.8 | Φ16 × 1.5 | 120 | Flat: 50×580×6 mm; Bridge: 675×500 mm; V-feet height: 270 mm | Hot-dipped galvanized (after welding) |

| 2.5 | 1100 | Φ38 × 2.0 | Φ12 mm steel rod | 150 | Flat: 50×580×6 mm; Bridge: 675×500 mm; V-feet height: 270 mm | Hot-dipped galvanized (after welding) |

| 2.5 | 1200 | Φ48 × 1.5 | Φ12 mm steel rod | 150 | Flat: 50×580×6 mm; Bridge: 675×500 mm; V-feet height: 270 mm | Hot-dipped galvanized (after welding) |

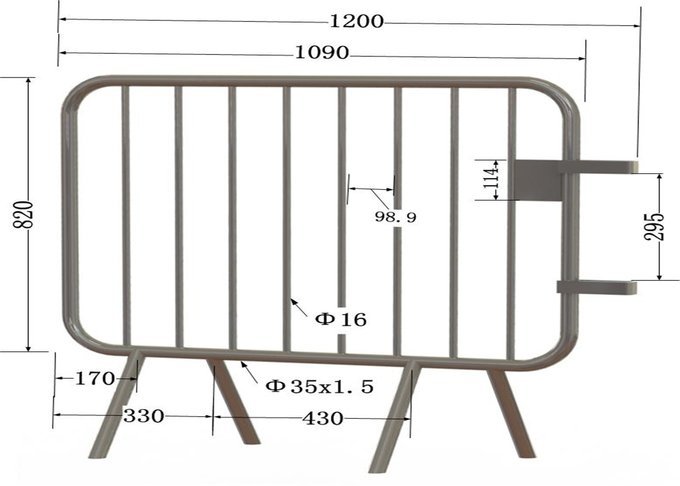

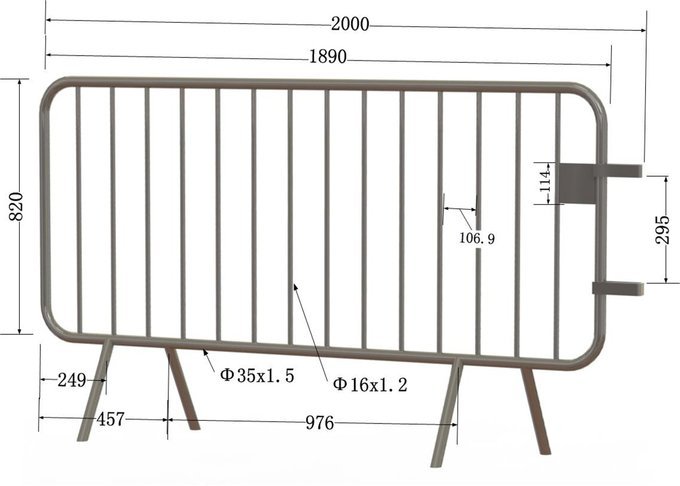

Customized Crowd Control Barrier (1200mm & 2000mm)

| 1200mm Width Belgium Crowd Control Barrier | 2000mm Width Belgium Crowd Control Barrier |

|---|---|

1200mm Width Crowd Control Barriers

|

2000mm Width Crowd Control Barriers

|

| Specification | 1200mm Width (mm) | 2000mm Width (mm) |

|---|---|---|

| Overall Height | 820 | 820 |

| Overall Width | 1200 | 2000 |

| Inner Width | 1090 | 1890 |

| Frame Diameter × Thickness | Ø35×1.5 | Ø35×1.5 |

| Inner Pipe Diameter | Ø16 | Ø16×1.2 |

| Feet Length | 430 | 976 |

| Feet Width | 330 | 457 |

| Distance Between Feet | 170 | 249 |

| Locking Space | 98.9 | 106.9 |

| Hook Length | 114.1 | 114.1 |

| Hook Gap | 295 | 295 |

| Total Height | 1050 | 1050 |

Different Types of Feet for Crowd Control Barriers

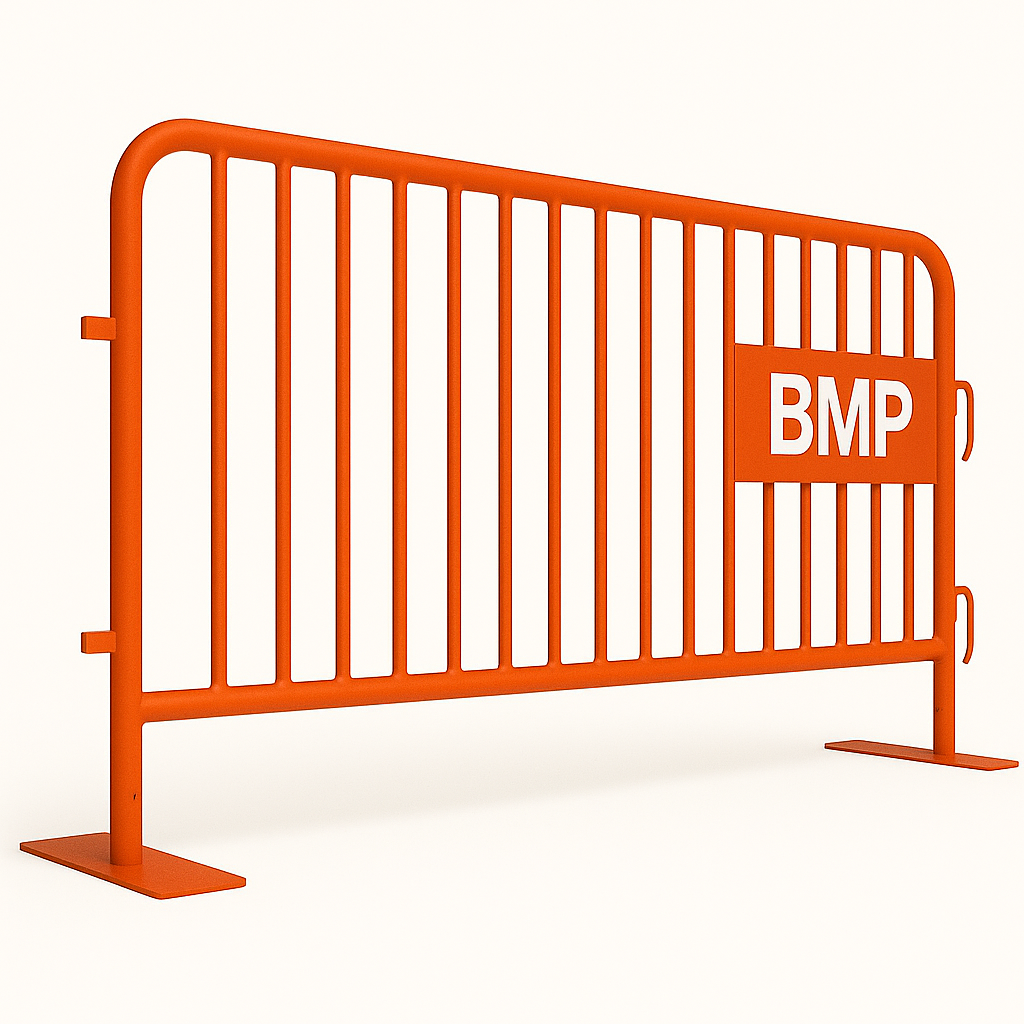

Crowd control barriers help guide people at events, construction sites, and roadwork, and the feet play a big role in keeping every panel stable and aligned. Most projects choose from three common options—flat feet, welded fixed feet, and bridge feet—because each style behaves differently on concrete, asphalt, grass, or uneven ground. If your site also needs clear instructions, branding, or “keep out” messaging on the barrier line, crowd control barrier signage is often added as a practical finishing step to improve visibility and reduce staff workload.

1. Flat Feet

Flat feet are the most popular type. They work well on flat surfaces like concrete, asphalt, or indoors. These feet make the barriers stable and easy to set up or move. Flat feet are a great choice for events like concerts or festivals because they reduce the chance of people tripping over them.

2. Welded Fixed Feet Crowd Control Barrier

Welded fixed feet stay attached to the barrier frame and provide strong support. These feet work well when you need the barriers to stay in place for a long time, such as at construction sites. Welded fixed feet handle tough conditions well and offer solid stability.

3. Bridge Feet

Bridge feet, also called arched feet, offer the best stability on uneven ground like grass or dirt. The arched shape spreads the weight better, making it harder for the barriers to tip over. Bridge feet are ideal for outdoor events or on rough ground where flat feet wouldn’t work as well.

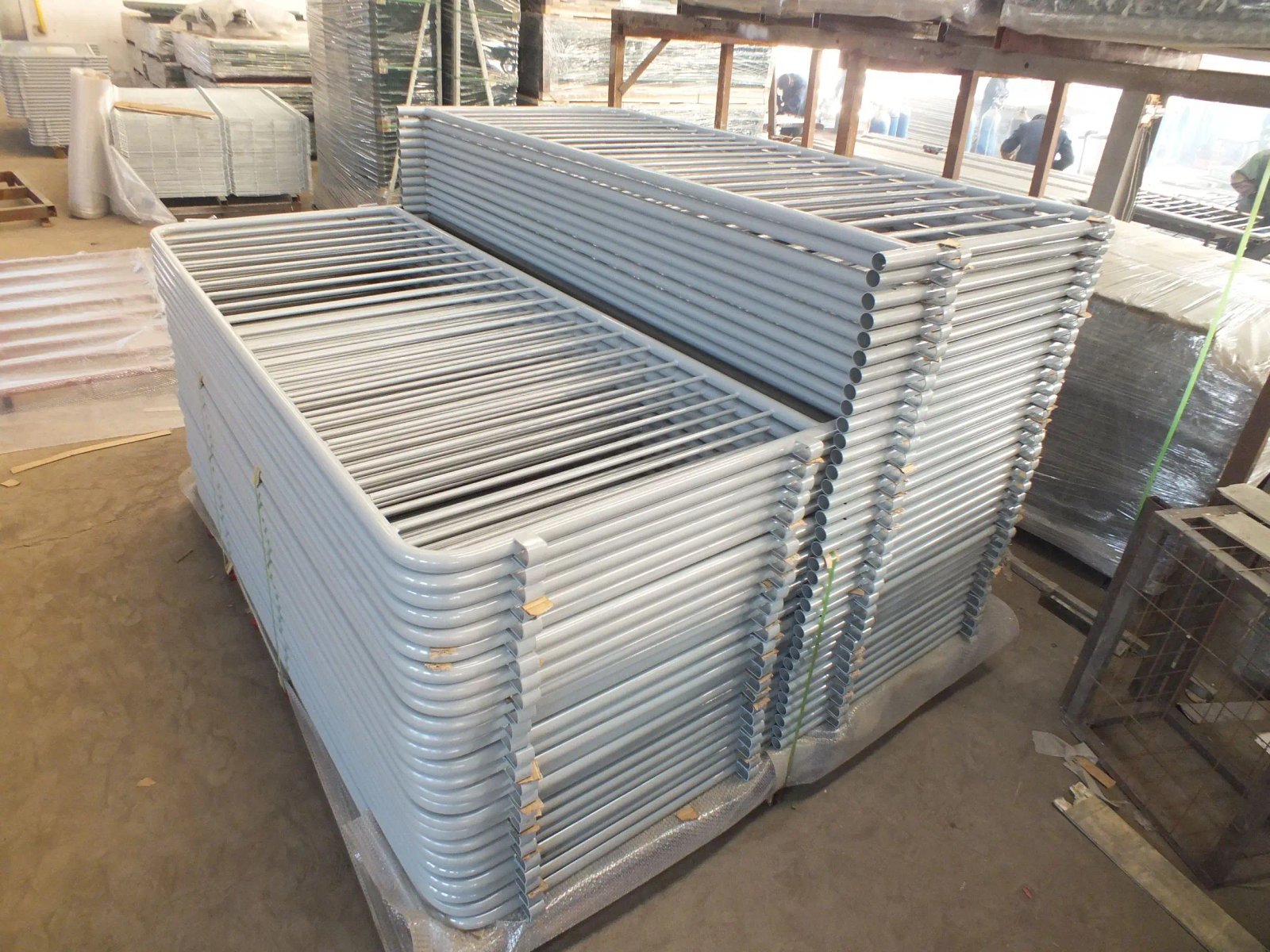

Crowd Control Barriers Packing

We offer several packing options for crowd control barrier based on customer needs. Each option provides different benefits to meet your specific requirements.

1. Standard Packing – Bulk

This option packs the barriers in bulk without using pallets. It saves space, reduces packaging costs, and lowers freight charges. It’s an efficient choice when cost savings are a priority.

2. Customized Packing – Pallet

In this option, we pack the crowd control barrier on pallets. While the cost is higher, it makes loading and unloading much easier, saving labor time and effort. It’s a great choice for those who want convenience during handling.

3. Custom Labels

We can provide custom labels based on your needs, making it easy to identify and organize the barriers during storage and transportation.

5. Packing Details

- Barrier Panels: Each barrier panel is wrapped with plastic bands for protection and then placed on pallets for easy handling and secure transport.

- Accessories: All accessories, like hooks and feet, are placed in plastic bags and then packed in cartons for safe keeping and easy access.

6. Different Packing Methods Crowd Control Barrier

- Stacked in Metal Pallets: Barriers are neatly stacked in metal pallets to save space and keep them stable during transit.

- Bulk Loading in Containers: Barriers are tightly packed in shipping containers for large-scale deliveries. This method makes the most of available space.

- Wrapped with Protective Material: For added protection, some barriers are wrapped in plastic or other materials to prevent scratches or minor damage during transportation.

- Horizontal and Vertical Stacking: Barriers can be stacked both horizontally and vertically, depending on the space, to ensure they remain secure and organized throughout the shipping process.

Storage Services

Our factory has a large, clean, and dry warehouse, which lets us hold your barriers for short-term storage when you’re coordinating site dates or waiting for the next shipping window. Everything is kept off the ground, protected, and clearly labeled so the products stay in good condition until they are ready for dispatch. Many projects also standardize their access points at the same time, so it’s common to pair the barrier line with matching garrison fencing gates to keep the full perimeter system consistent on site.

|

|

|

|

Applications Crowd control barriers

- Public Events and Gatherings: Crowd control barriers are used to manage pedestrian traffic during large public events, such as concerts, festivals, and parades. They help create clear pathways and control the movement of people.

- Construction Sites: The barriers are placed around construction sites to ensure safety by keeping unauthorized personnel out and directing pedestrian flow around the work zone.

- Road and Traffic Management: Barriers are deployed on roads to manage and direct traffic during construction, repairs, or events that require rerouting vehicles and pedestrians.

- Parks and Public Spaces: Crowd control barriers are used in parks to section off areas, create designated pathways, and protect certain spots from being accessed by the public.

- Sidewalk and Street Work: Barriers help create a protective buffer between ongoing street work or sidewalk repairs and pedestrians. They prevent people from entering dangerous areas.

- Event Venues and Sports Grounds: At sporting events, barriers ensure the separation of different zones, such as spectator areas, VIP sections, and player entry points.

FAQ Crowd control barriers

Are the welding points strong?

The welding points won’t break easily. We test the strength during production to make sure they hold up well.

Do the barriers rust?

No, they don’t rust easily. Before we paint them, the barriers go through cleaning and sand-blasting. We use top-quality powder coatings from brands like Dupont and Aksu. This makes sure the barriers stay smooth, strong, and resistant to UV rays and rust.

What happens if the product doesn’t meet my standards?

We carefully check every product to keep the defect rate low, below 0.1%. If there’s any problem, we will solve it within 2 working days after you send photos or videos of the issue.

Can I get a sample?

Yes, we can send a sample if we have parts in stock. You will need to pay for the delivery. Once you place an order, we will refund the sample cost.

How long is the warranty for the Crowd Control Barrier?

Our barriers last at least 10 years. We usually give a warranty between 5 to 10 years.

Can I become your agent?

We are open to partnerships. Please email us for more details, and we can discuss further cooperation.

What kind of after-sales service do you offer?

We track your order after shipping and give you updates. After you receive the goods, we will check in with you. If there’s any issue, we will respond within 2 working days.

Can you make custom barriers?

Yes, we can. We build the barriers based on your needs and also offer advice to help you get the best results.

Crowd Control Barriers