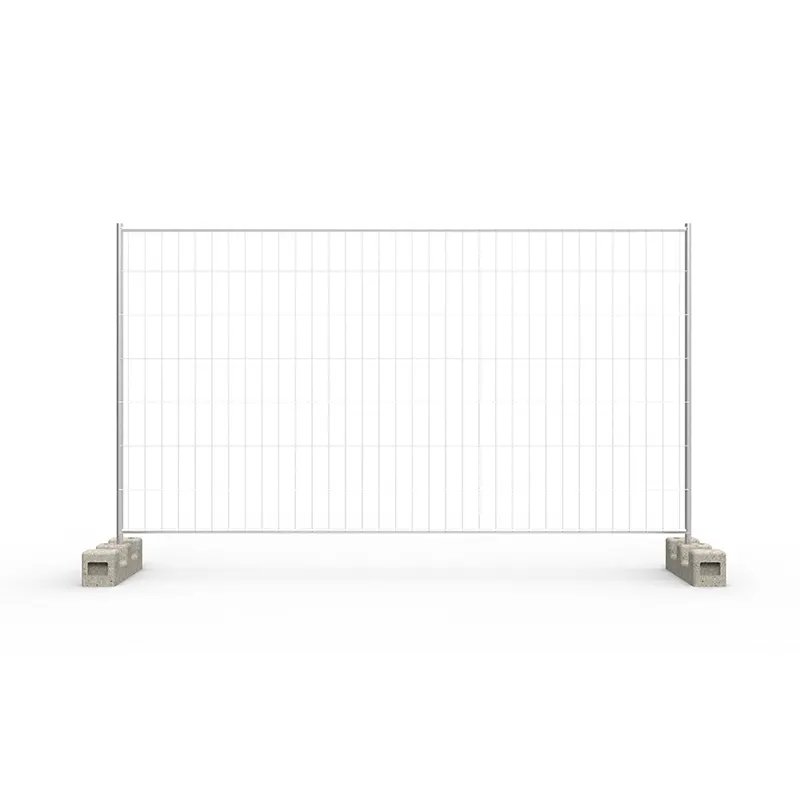

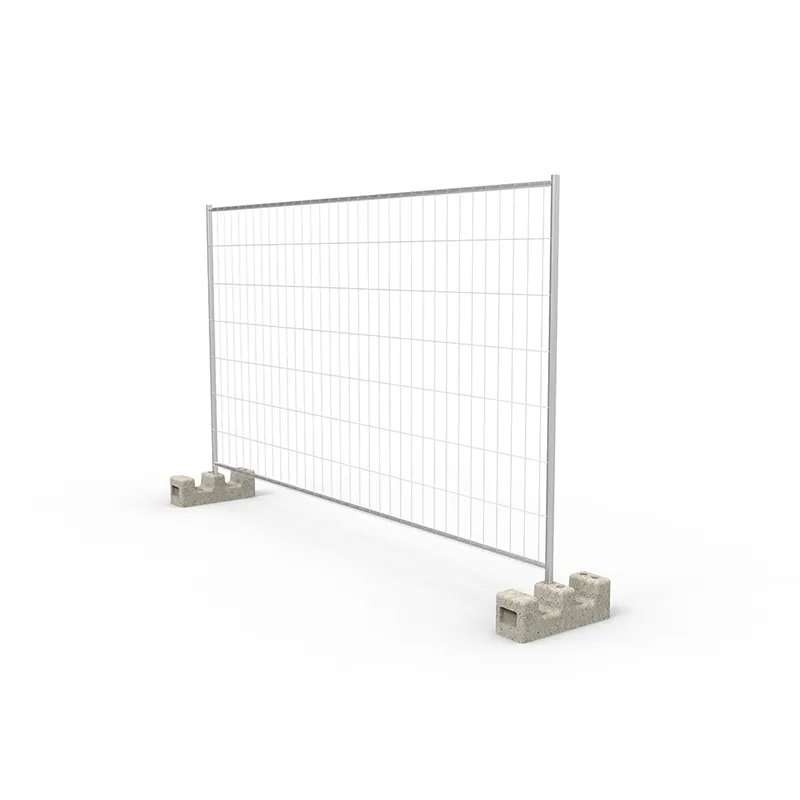

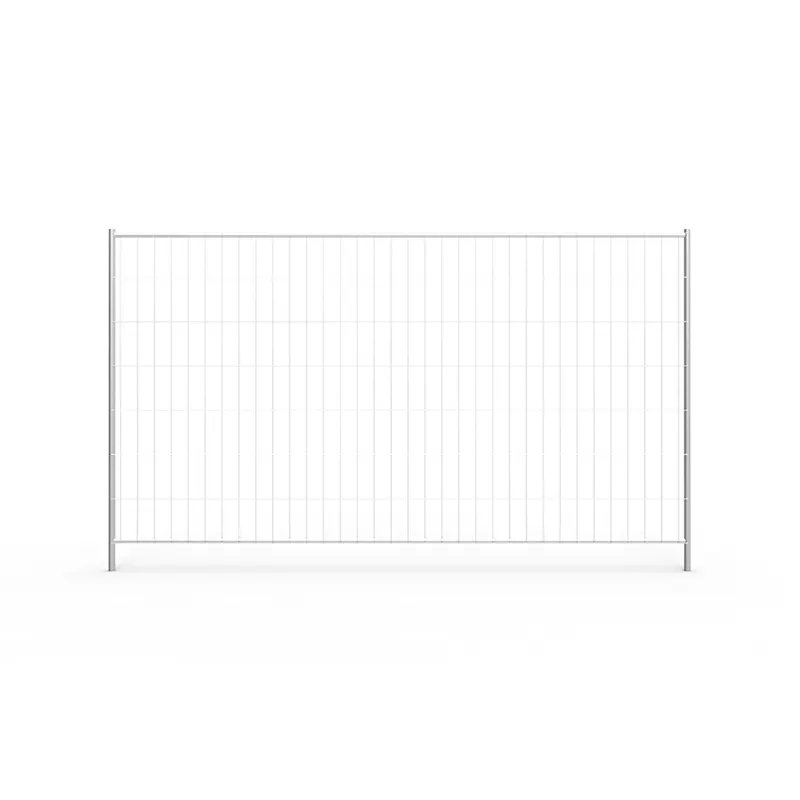

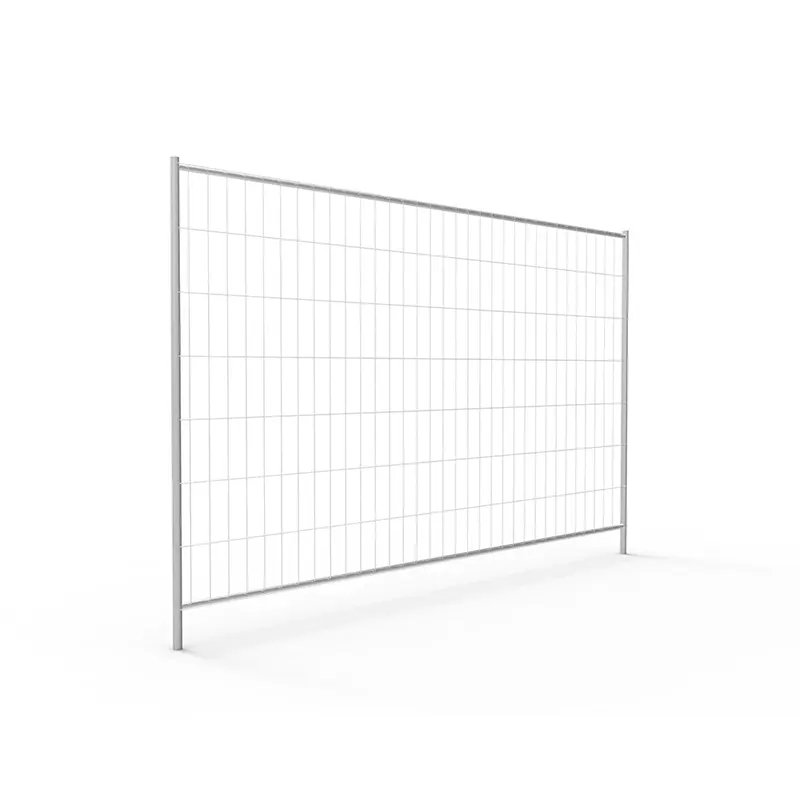

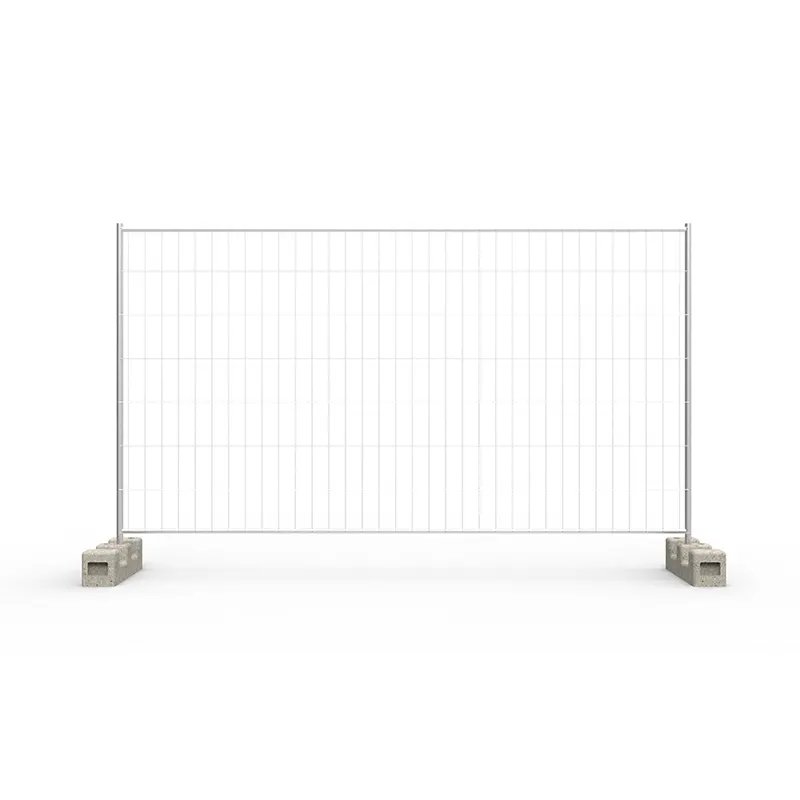

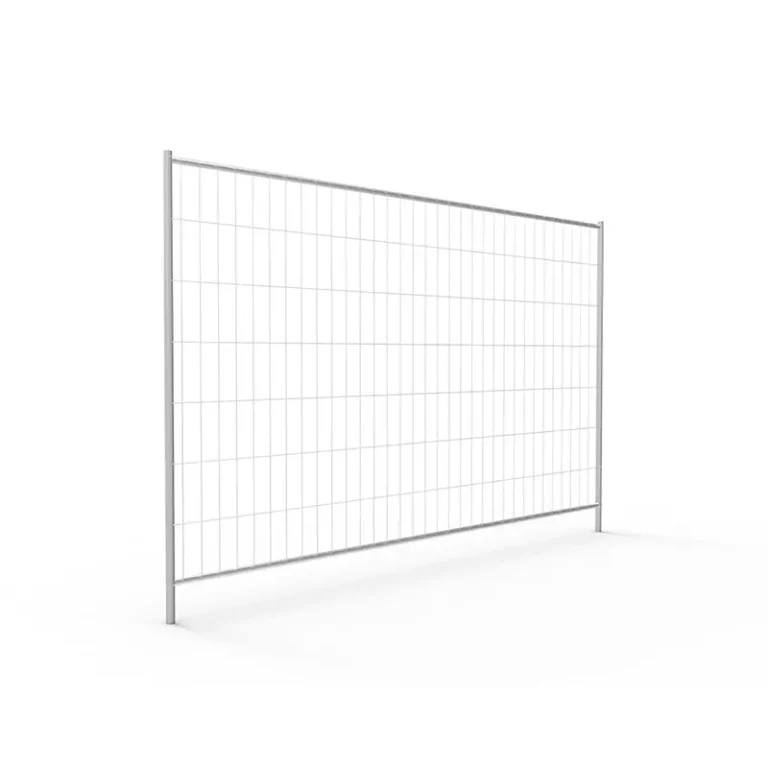

Temporary Construction Fence

- Standard panel size: 3452 mm (L) × 2025 mm (H)

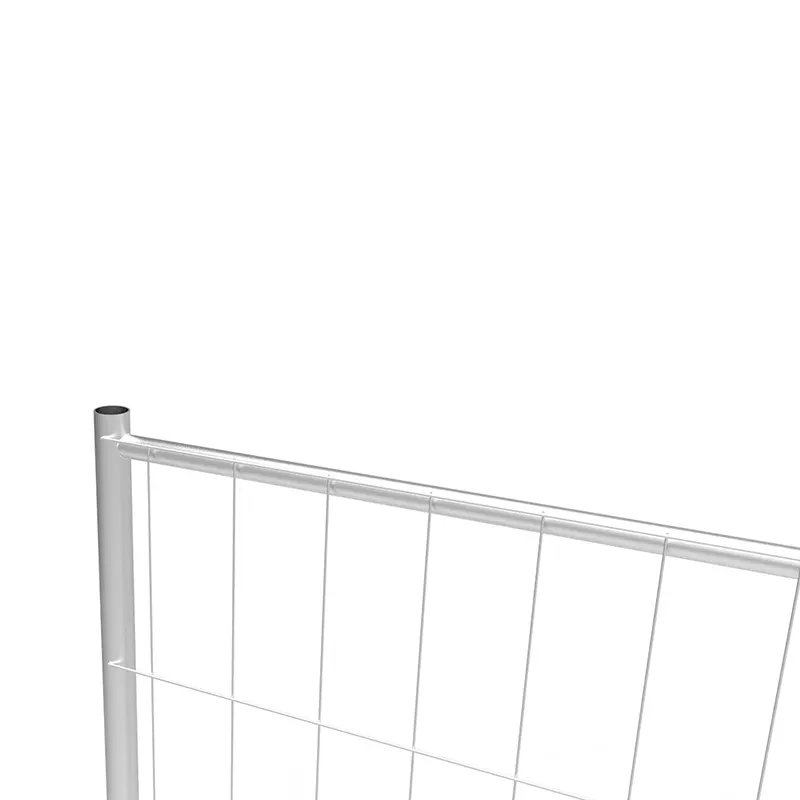

- Frame tube (uprights/crossbars): Ø40 mm

- Horizontal inner tube: Ø30 mm

- Mesh aperture: 100 × 262 mm

- Wire diameter (horizontal): Ø3.2 mm

- Wire diameter (vertical): Ø3.2 mm

- Panel weight: ≈15 kg

- Standard finish: Pre-galvanized

- Optional coatings (process notes): Zinc-rich epoxy primer/topcoat; hot-dip galvanized variants referenced in features

- Stability aids: Panel stays/braces; robust feet; secure couplers

- Accessories (examples): Hinges; ground anchors; jockey wheels; bases/feet; panel stays; galvanized clamps/couplers; anti-tamper clamps

- Key features: Durable, corrosion-resistant; portable yet strong; quick install/removal; reusable

- Description

Purpose-built for temporary site security, these Temporary Construction Fence assemble quickly, stand up to weather, and pack down for reuse. They’re a reliable choice for construction sites, sporting events, festivals, outdoor activations, and safety/exclusion zones.

|

|

|

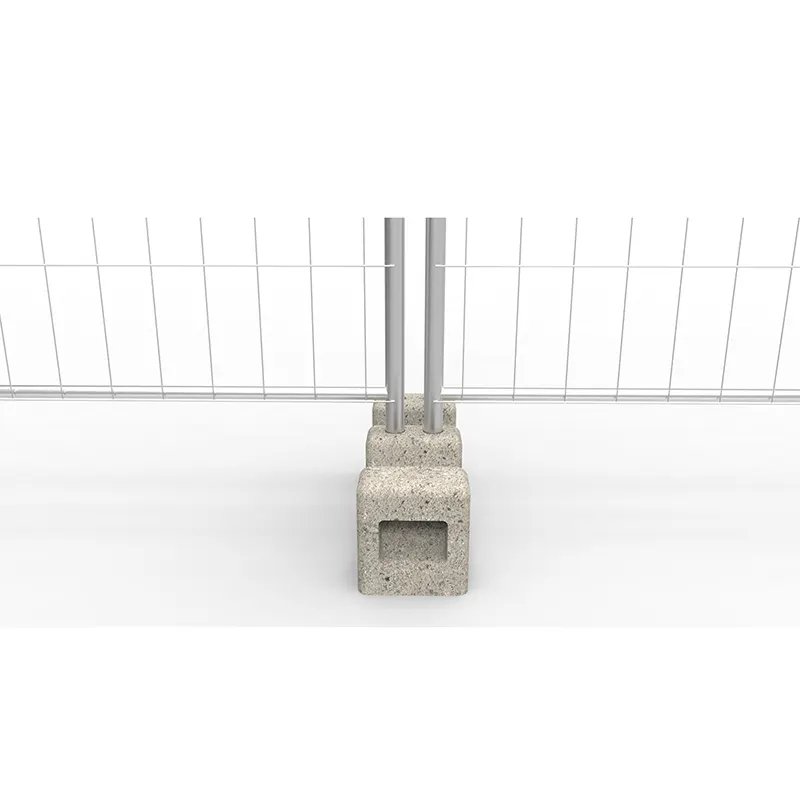

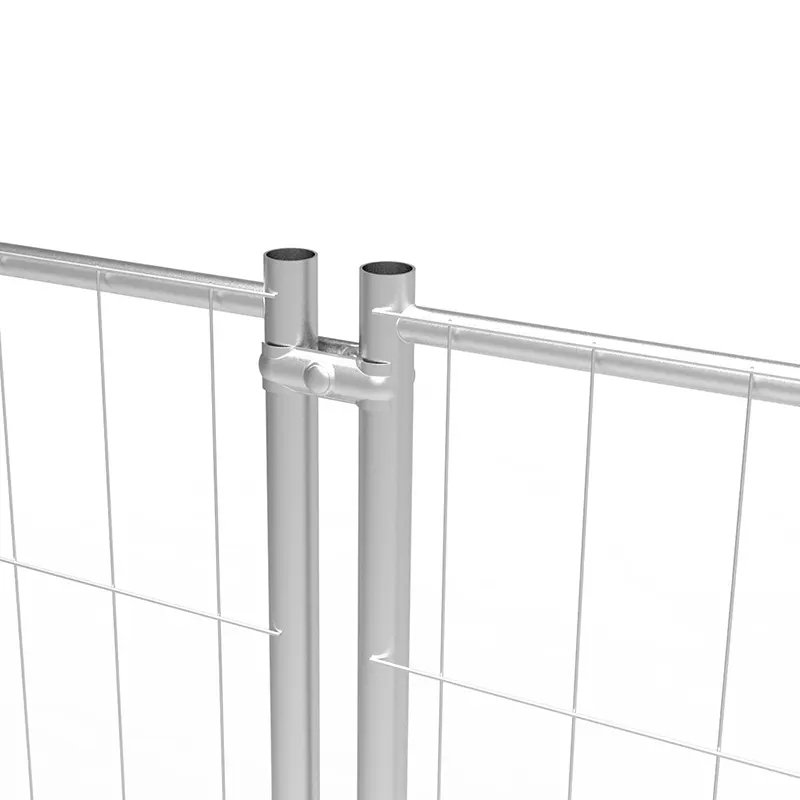

| Temporary Fencing Panel | Temporary Fencing Base | Temporary Fencing Welding |

Why These Temporary Construction Fence Panels

- Wind-permeable mesh: Allows air to pass through, reducing wind load and the risk of panel blow-over.

- Fast install, clean removal: Drop-in feet and couplers/clamps make setup and teardown quick—no special tools.

- Stable & secure: Rigid welded frame with braced feet and stays for long runs or corners.

- Reusable & portable: Pre-galvanized steel keeps weight reasonable for handling and transport.

- Configure any layout: Panels connect to form straight lines, corners, or enclosures of almost any length/shape.

Standard Size & Specifications Temporary Construction Fence

| Attribute | Spec |

|---|---|

| Panel dimensions | 3452 mm (L) × 2025 mm (H) |

| Frame tube (uprights/crossbars) | Ø40 mm |

| Horizontal inner tube | Ø30 mm |

| Mesh aperture | 100 × 262 mm |

| Wire diameter (H/V) | Ø3.2 mm / Ø3.2 mm |

| Panel weight | ≈ 15 kg |

| Finish | Pre-galvanized steel (zinc-coated); zinc-rich primer and topcoat available on request |

Need other sizes, colours, or mesh densities? Panels can be customised for specific sites or branding.

Features You’ll Notice on Site

- All-round welds: Tubes are 360° fully welded for a solid, long-lasting frame.

- Couplers & feet: Standard clamps/couplers and temporary fence feet (concrete or recycled-rubber options).

- Stays & bracing: Panel stays for added stability in windy or high-traffic areas.

- Accessory-ready: Hinge sets, ground anchors, jockey wheels, and security clamps available.

- Surface prep options: Zinc-rich primers or finishing coats to boost corrosion resistance where specified.

Temporary Fencing Systems:

|

|

|

| Fence Hinge | Fence Ground Anchor | Fence Jockey Wheel |

|

|

|

| Fence Base | Fence Panel Stay | Temporary Fence Clamps |

System Accessories (Typical)

- Bases/feet (concrete or rubber)

- Galvanized clamps/couplers

- Panel stays/braces

- Hinges (create swing access), jockey wheel (gate panel support)

- Ground anchors and anti-tamper clamps

Manufacturing Process (Simplified)

- Material inspection — verify galvanized pipe and wire to spec.

- Pipe cutting & end stamping — cut to length; flatten ends as required.

- Mesh welding — straighten wires; weld into mesh sheets by automated line.

- Frame welding — assemble uprights/crossbars; weld mesh to frame.

- Scarfing/clean-up — remove slag; touch up zinc where needed.

- Protective coatings (optional) — brush/spray zinc-rich epoxy primer and finish coat if specified.

- Quality control — check weld integrity, wire gauge, mesh size, coating consistency.

- Packaging — stack and strap for safe transport and quick site unloading.

FAQs Temporary Construction Fence

- Custom builds? Yes—panel size, mesh aperture, colour, branding, and hardware.

- Faster delivery? Share quantities and configuration early; we’ll optimise production and logistics.

- Samples? Usually free; freight at cost (lead time ~7–10 days for standard samples).

- Lead time? Depends on quantity and options; high-capacity lines keep turnaround short.

- Experience? Dedicated design, manufacturing, and shipping teams with 10+ years in fencing.

Temporary Fencing, Temporary Fence Panels

SEND INQUIRY

Related Products

© BMP All rights reserved