RMS Pedestrian Fencing

- Hot-dip galvanized after welding

- Powder coated

- Duplex: Powder coated after hot-dip galvanizing

- Welding: AS/NZS 1554.1:2014

- Galvanizing: AS/NZS 4680:2006

- Powder coating: AS 4506—2005

- No sharp or protruding parts (public-safe design)

- Optimized height and spacing preserve pedestrian/driver sightlines

- High-strength steel + protective coatings for durability, corrosion resistance

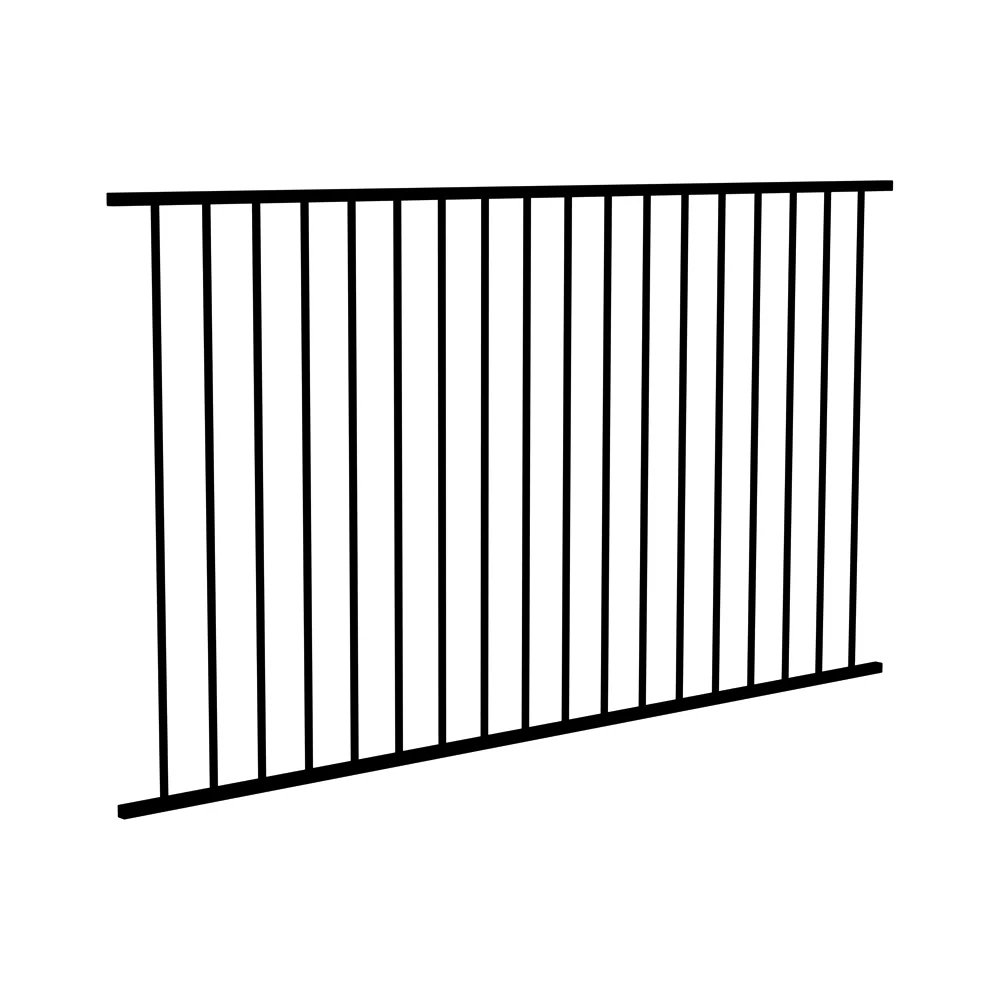

- Description

BMP’s RMS Pedestrian Fencing is engineered for public areas, schools, parks, and busy road corridors. The system uses heavy-duty steel, nut-and-bolt connections, and welded assemblies to deliver stable, impact-resistant barriers that guide pedestrians to safe crossing points and improve driver visibility.

|

|

Key Features

-

Impact guidance: Rails and offsets help channel pedestrians toward designated crossings and deter mid-block entry.

-

Driver sightlines: Offset verticals reduce visual blockage so approaching drivers can see pedestrian movement.

-

Robust build: High-strength steel, welded construction, and anchored base plates for long service life.

-

Flexible deployment: Suitable for public hubs, main roads, school zones, and high-footfall precincts.

Materials & Finishes

-

Base material: High-strength steel

-

Galvanizing: Hot-dip galvanized after welding for complete coverage

-

Coatings:

-

Powder coated

-

Duplex option: Powder coated over hot-dip galvanized for enhanced durability

-

-

Colour: Black standard; custom colours available by request

Compliance & Standards RMS Pedestrian Fencing

Designed to align with relevant Australian standards:

-

Welding: AS/NZS 1554.1:2014

-

Galvanizing: AS/NZS 4680:2006

-

Powder coating: AS 4506—2005

Product Details

-

High-quality galvanized steel throughout

-

Welded frames for overall strength and stability

-

Column base plates welded and secured with anchor screws and hardware

-

Powder-coat finish options for corrosion and abrasion resistance

|

|

|

|

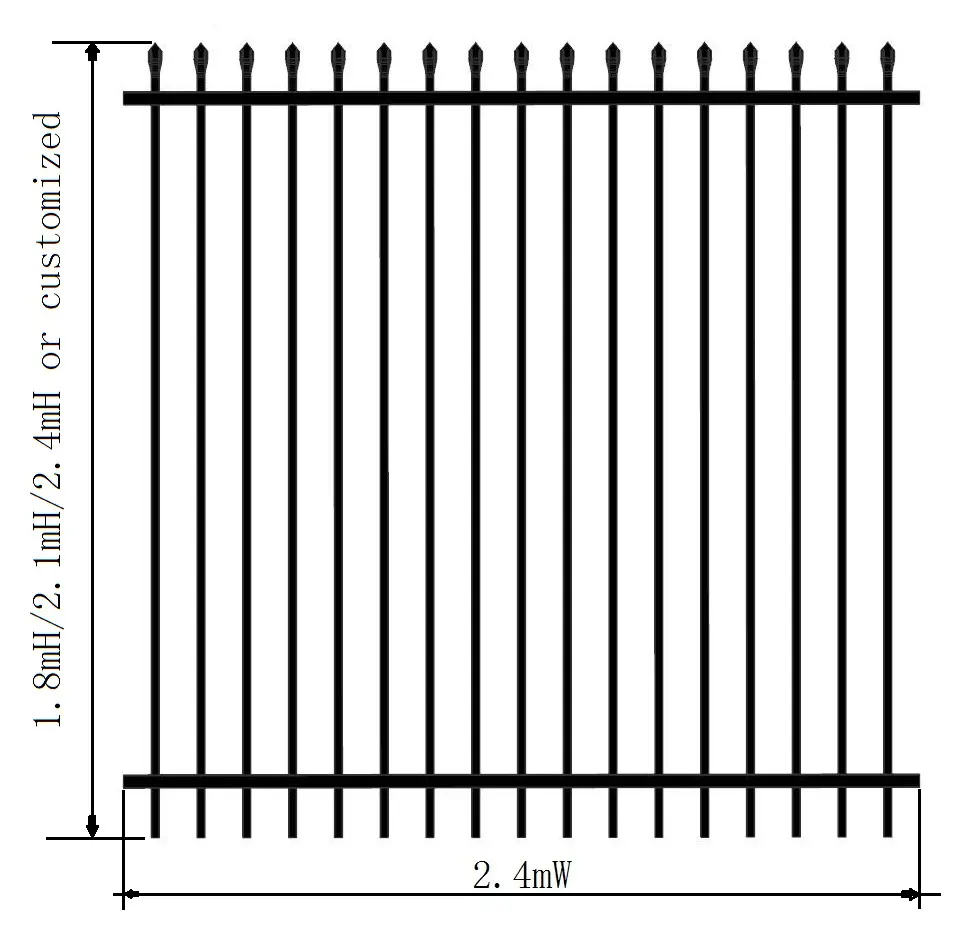

Specifications

-

Panel size (mm): 2000 × 1050

-

Frame (mm): Two × 75 × 10 flat bars with 75 × 50 × 8 unequal-angle brackets

-

Infill (mm): 1650 × 90 × 50 (module as supplied)

-

Intermediate post: Three post designs available to suit differing site needs

-

Surface treatment options:

-

Hot-dip galvanized after welding

-

Powder coated

-

Powder coated after hot-dip galvanizing (duplex)

-

Notes: Dimensions and module details reflect the standard configuration. Project drawings confirm exact post type, footing details, bolt patterns, and panel spacing.

Advantages RMS Pedestrian Fencing

-

Protects pedestrians from roadside hazards and funnels movement to safer locations

-

No sharp or protruding parts—reduces injury risk for the public and maintenance crews

-

Optimised height and bar spacing preserve sightlines and reduce distraction

-

High-strength steel for durability and consistent safety performance

-

Can be manufactured to meet various national or state road authority requirements

-

Professional packaging for secure, damage-free transport

Typical Applications

-

Intersections and median islands

-

School frontages and pick-up/drop-off zones

-

Tourist attractions and event precincts

-

Shared spaces, activity areas, and transport hubs

-

Main roads and approaches to pedestrian crossings

Ordering & FAQs RMS Pedestrian Fencing

Q: Can you design to our brief?

A: Yes. Share your requirements (drawings, dimensions, photos, or a verbal brief) and our engineering team will produce a tailored design.

Q: We need product quickly—what helps?

A: Tell us the quantities and configurations. We’ll plan the most efficient production sequence and confirm realistic lead times.

Q: Sample timing and cost?

A: For custom samples that don’t require a new mould, typical lead time is 7–10 days. Samples are free; freight is customer-paid.

Q: Delivery time?

A: Dependent on quantity and specification. Our large-scale facility supports fast throughput; timing is confirmed in your quotation.

Q: Can you customise?

A: Yes—size, materials, colour, and workmanship can be tailored to site conditions and authority requirements.

Q: What’s the MOQ for a trial order?

A: Typically one full 1×20′ container to protect products in transit. We can discuss flexible quantities if needed.

Aluminum fence